Two-dimensional code printing mold

A two-dimensional code and mold technology, applied in the field of two-dimensional codes, can solve the problems of troublesome two-dimensional codes and affect the appearance of products, and achieve the effects of simple structure, wide application range, and simple and easy printing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more clearly understood, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

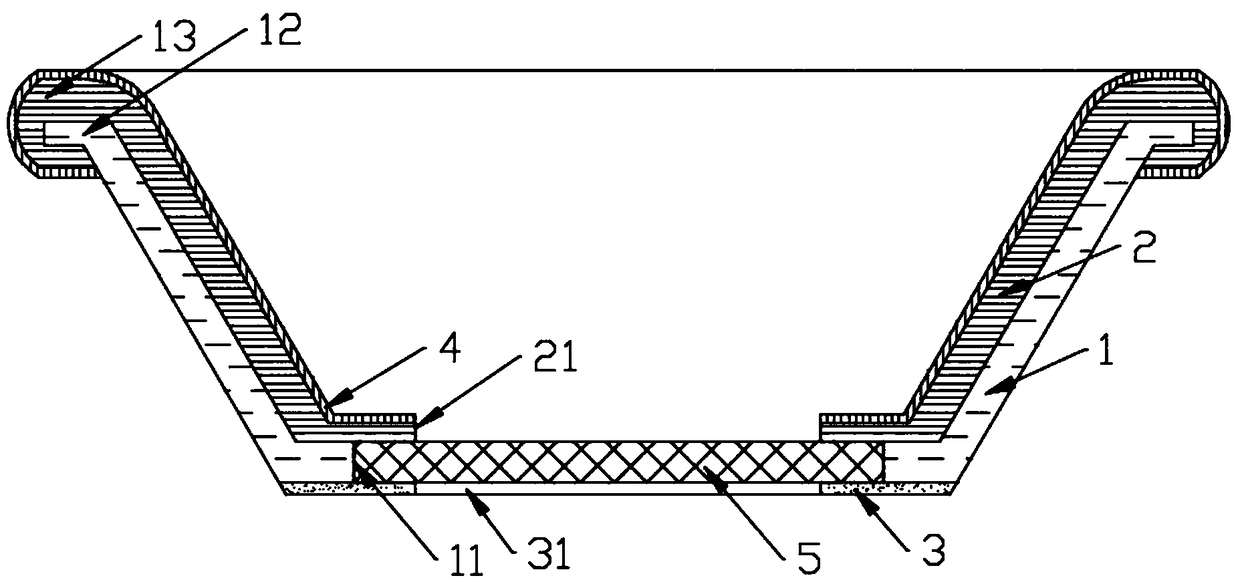

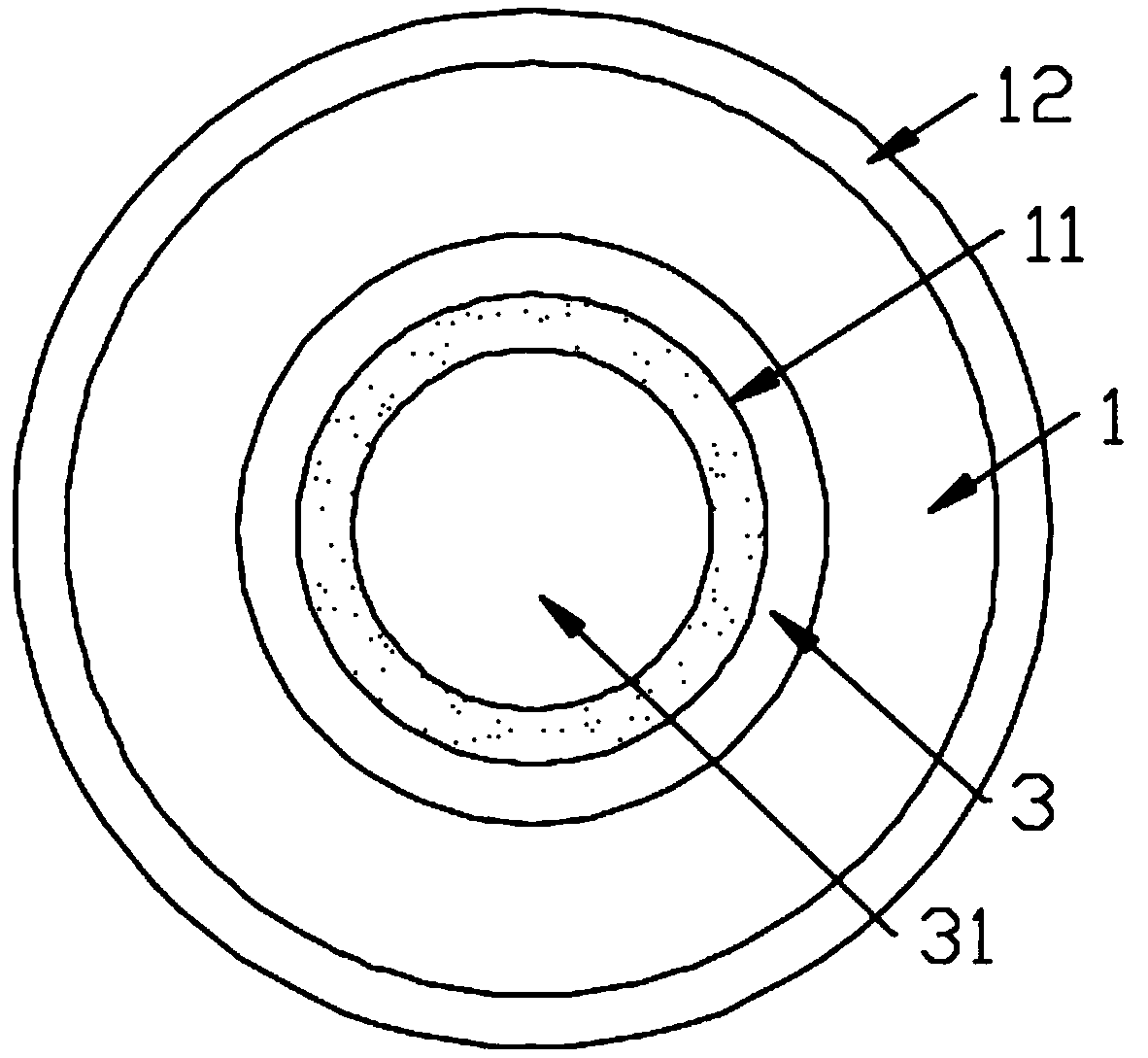

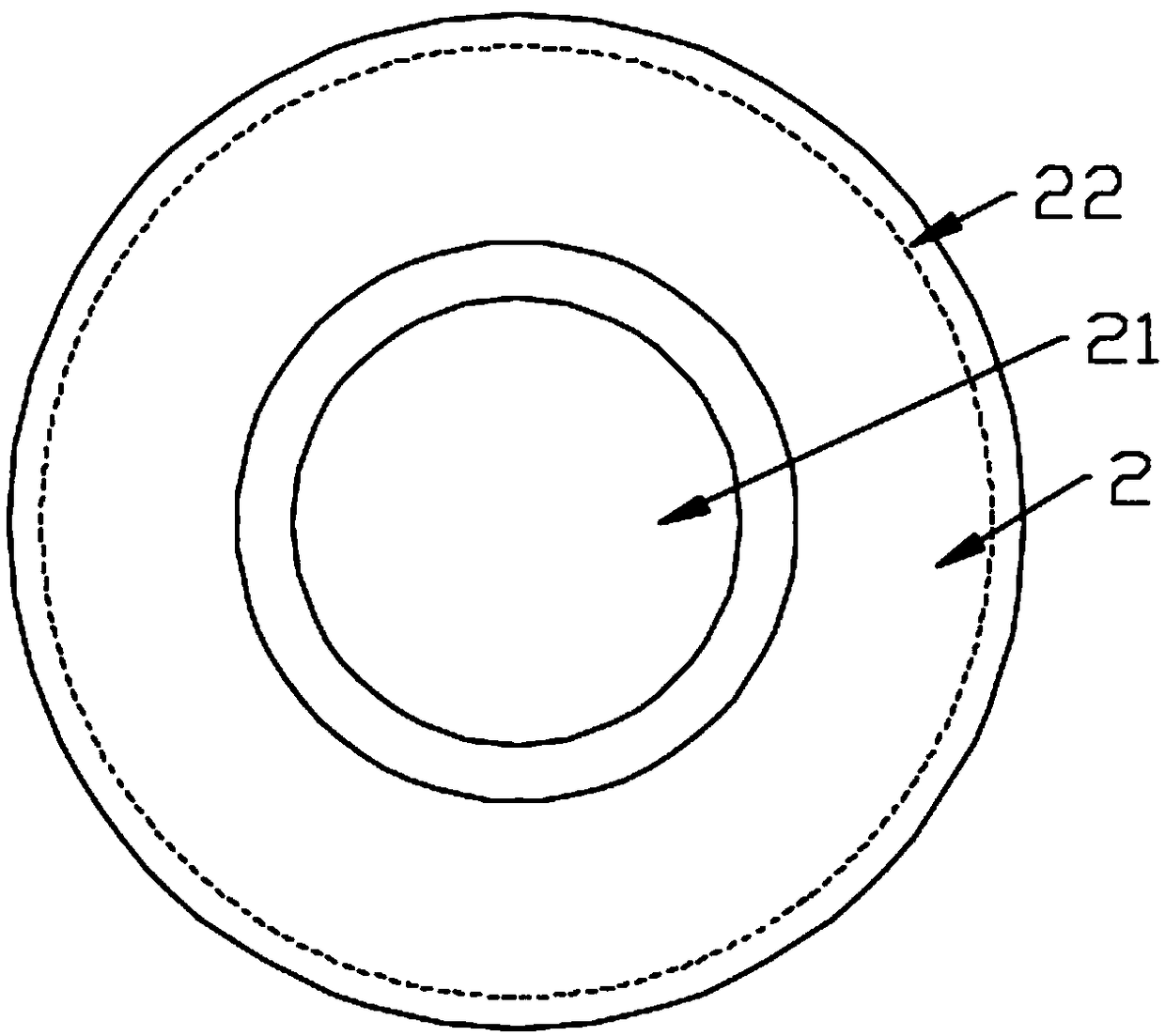

[0024] Such as Figure 1-Figure 3 Shown, a kind of two-dimensional code printing mould, comprises mold one 1 and the mold two 2 that is socketed in mold one 1 inside, the bottom surface of mold one 1 is affixed with adhesive layer 3, the bottom surface of mold one 1 and the adhesive layer 3 The center is respectively provided with a through hole 11 and a through hole 31, and the top of the outer wall of the mold one 1 is provided with a fixed ring 12; The top of two 2 extends outwards to form a fixed buckle 22. Wherein, the diameter of the first through hole 11 is greater than the diameter of the third through hole 31 , and the diameter of the second through hole 21 is the same as that of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com