Pin inserting type wooden comb machining device and using method

A processing device and pin insertion technology, which is applied in the direction of wood processing equipment, workpiece clamping devices, manufacturing tools, etc., can solve the problem of insufficient connection between the comb needle and the comb body, insufficient strength of manual installation, and increased frequency of comb teeth replacement and other problems, to achieve the effect of facilitating replacement and maintenance, improving processing efficiency, and simplifying the use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

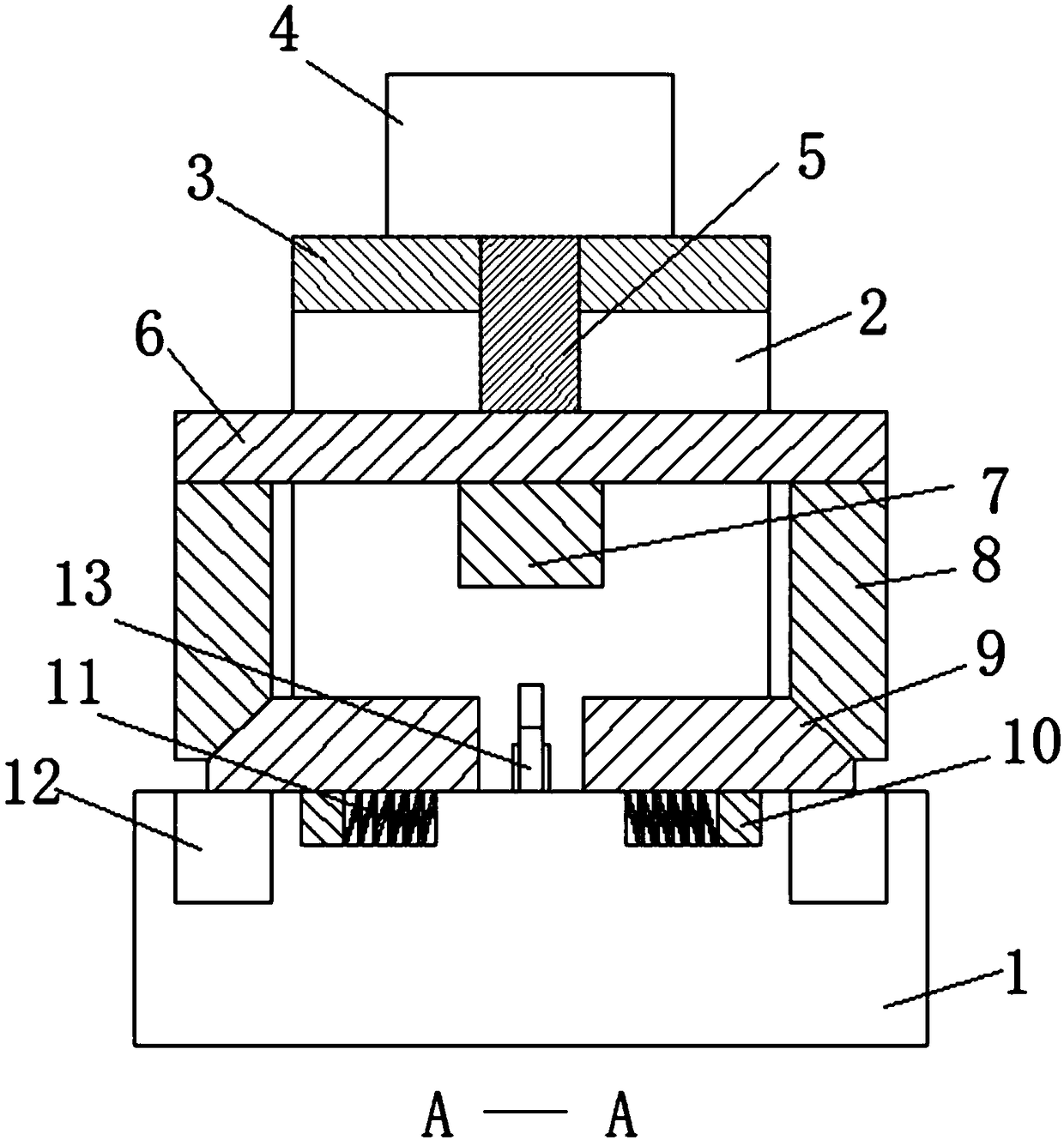

[0028] A pin-type wooden comb processing device, please refer to figure 1 with figure 2 , including: base 1, support rod 2, fixed plate 3, power components, upper and lower pressing mechanism and left and right clamping mechanism, there is a notch or comb body positioning seat 13 for placing workpieces on the base, and the upper end of support rod 2 is connected and fixed Plate 3, the lower end of the support rod 2 is connected to the base 1, the power part is installed on the fixed plate 3, the power part is the cylinder 4 or oil cylinder, the cylinder 4 is connected to the upper and lower pressing mechanism, the left and right clamping mechanism is connected to the upper and lower pressing mechanism and realizes linkage with it, The workpiece is directly below the upper and lower pressing mechanism.

[0029] The upper and lower pressing mechanisms include a lower pressing rod 5, a pressing plate 6 and a pressing block 7. The upper end of the lower pressing rod 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com