Movable welding fume dust collecting device

A technology of vacuuming device and welding fume, applied in the direction of removing smoke and dust, auxiliary devices, welding equipment, etc., can solve the problems of large area, pollution, harm to the health of workers, etc., to achieve the effect of convenient extension and movement, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solution of the present invention. The protection scope of the present invention includes but is not limited to In the following embodiments, any modifications made to the details and forms of the technical solutions of the present invention without departing from the spirit and scope of the present application fall within the protection scope of the present invention.

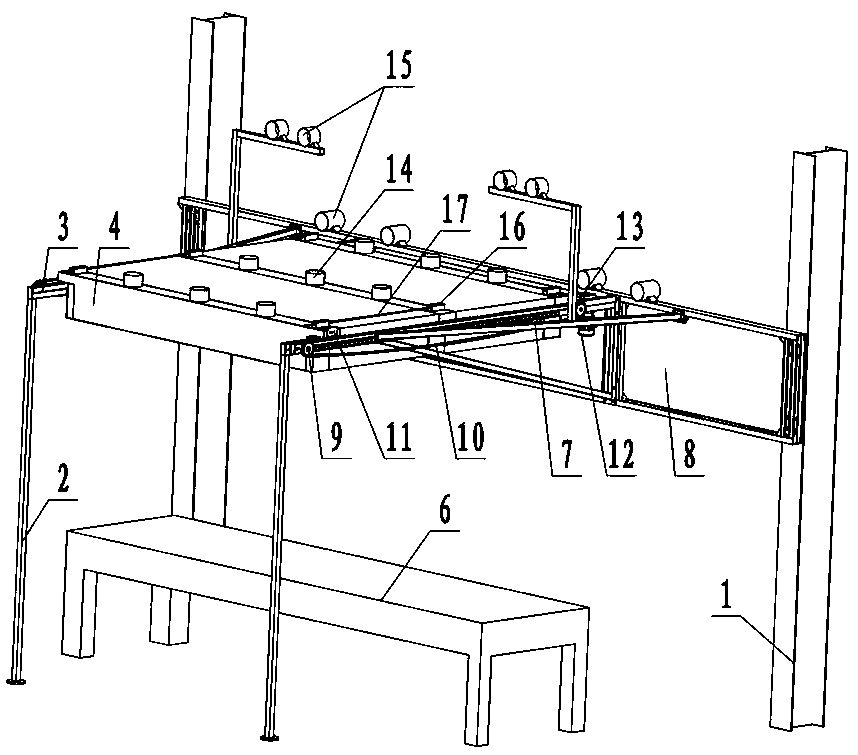

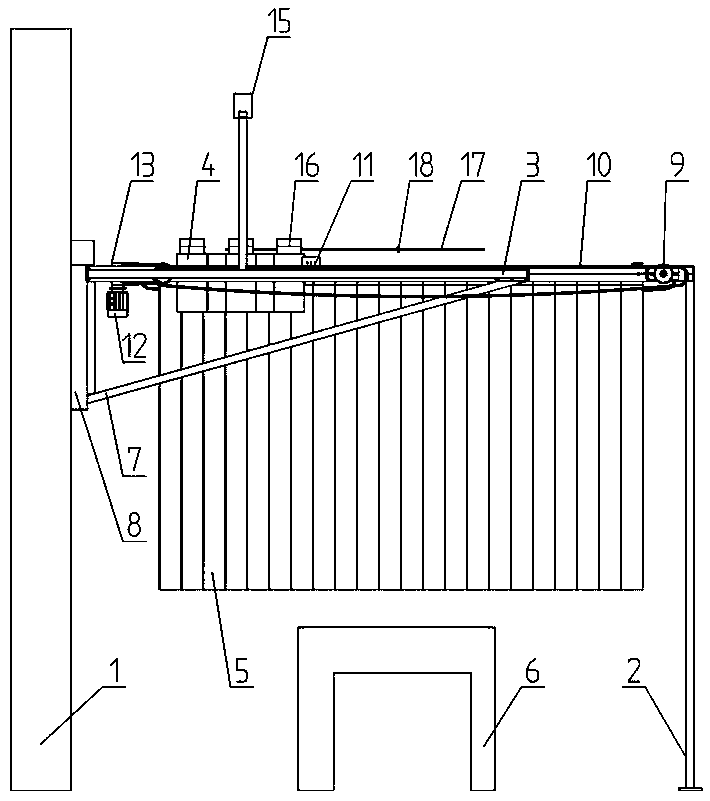

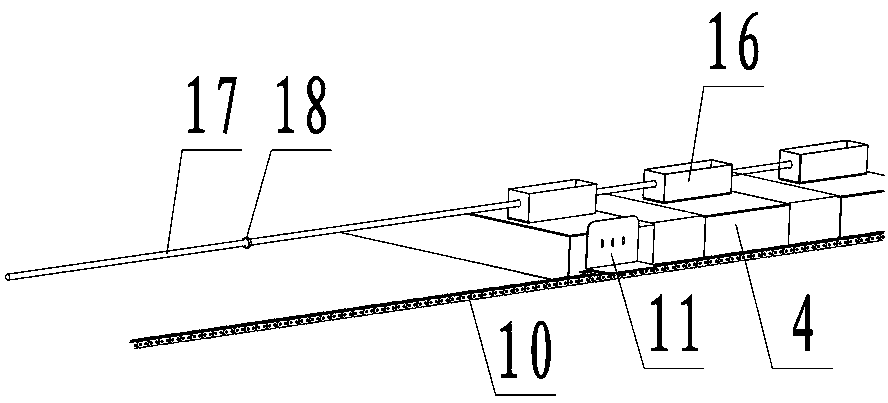

[0019] The drawings are a specific embodiment of the present invention. This embodiment includes a workshop column 1, a smoke collecting hood bracket 2 and a telescopic smoke collecting hood 4. The telescopic smoke collecting hood 4 is an organ telescopic protective cover, which is expanded and contracted by the expansion and compression of the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com