Self-adaptive steel ball sorting device based on electric eddy current testing

A sorting device and self-adaptive technology, applied in the field of machinery, can solve the problems of being easily affected by subjective factors, low degree of equipment self-adaptation, and difficult to guarantee the quality of steel balls, so as to achieve a simple and reliable overall structure and low sorting costs. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

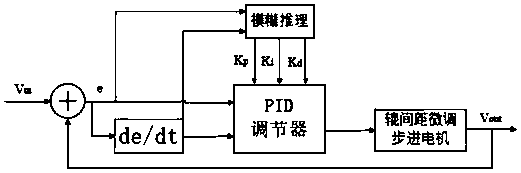

[0034] Embodiment 1 provides an adaptive sorting device for steel balls based on eddy current detection, which has a high degree of self-adaptation, accurate sorting, and high sorting efficiency.

[0035] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

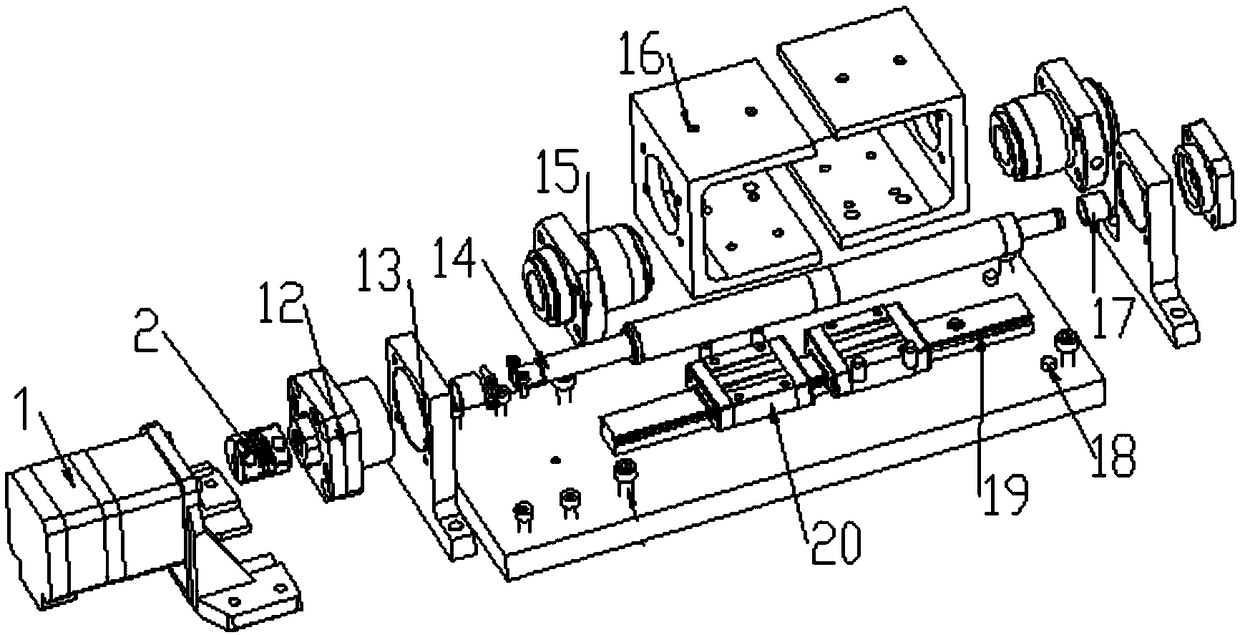

[0036] Such as Figure 1 to Figure 7 As shown, an adaptive sorting device for steel balls based on eddy current detection, including a steel ball sorting unit, a fine-tuning unit for the gap between sorting rollers, a drive unit, an eddy current detection unit and a steel ball collection unit;

[0037] Steel ball sorting unit:

[0038] Including the left sorting roller 6 and the right sorting roller 61 that are arranged in parallel, the left sorting roller 6 and the right sorting roller 61 are all stepped, and the two ends of the left sorting roller 6 and the right sorting roller 61 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com