Smoke suppression and dust falling system and method facing centralized slag loading area

A technology of slag loading and dust suppression, which is applied in the direction of separation methods, chemical instruments and methods, separation devices, etc., can solve the problems of unfriendly working conditions, poor construction environment, poor dust suppression effect, etc., and achieve the reduction of construction supporting investment and efficiency Improvement, the effect that the effect is direct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

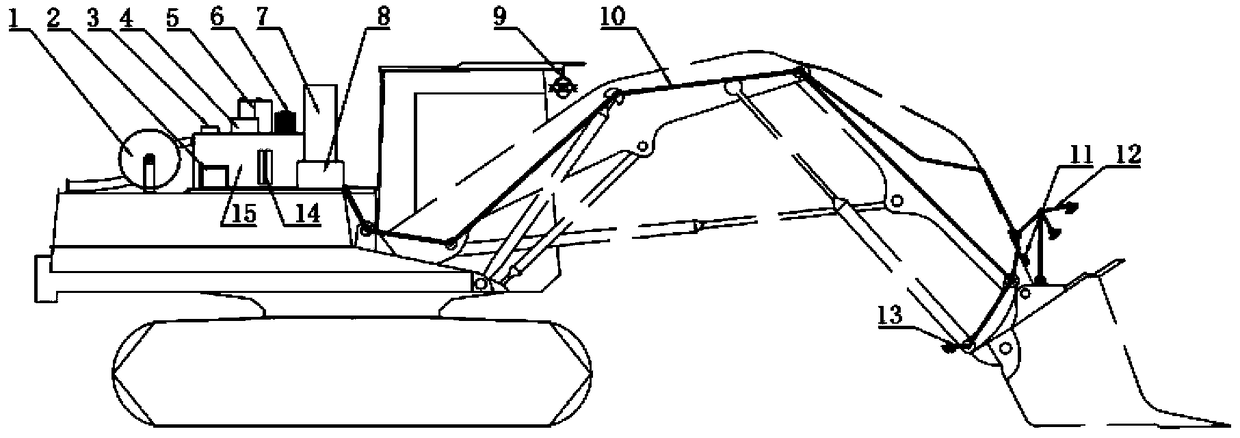

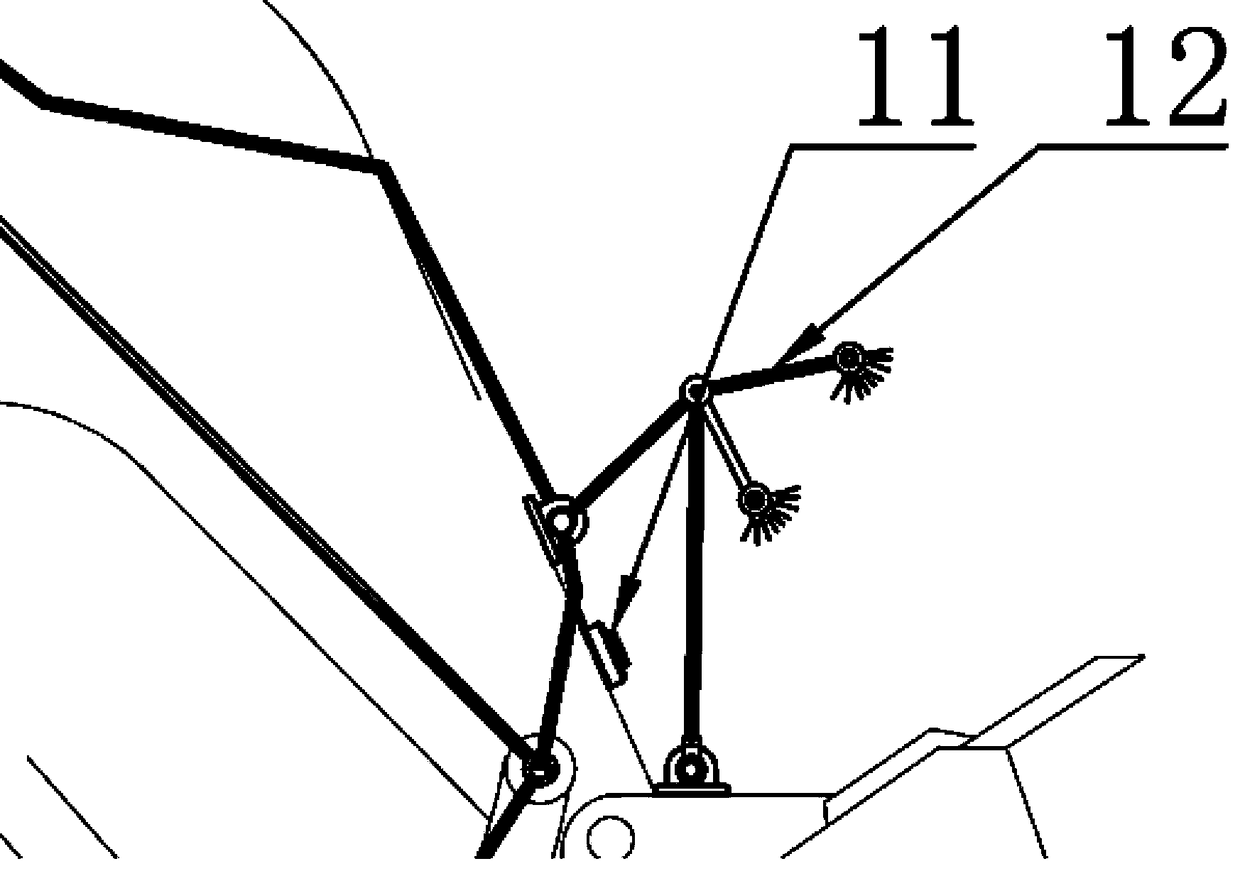

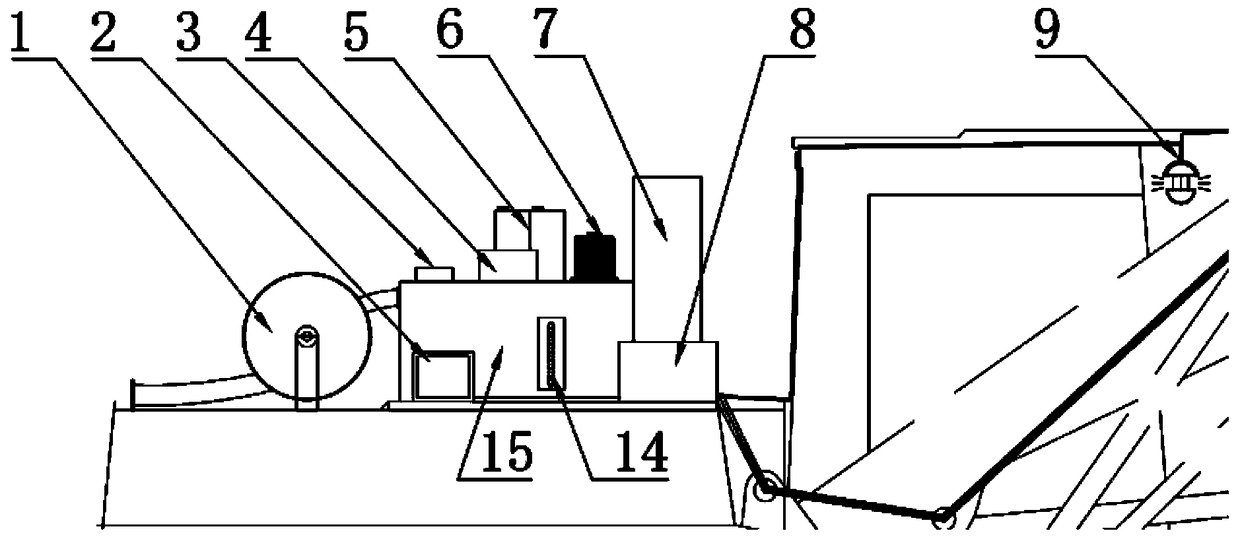

[0036] see Figure 1-3 , a smoke elimination and dust reduction system facing the centralized slag loading area, which includes a walking construction machine for cleaning the slag in the slag loading area; the walking construction machine is equipped with a smoke detection device for monitoring the amount of smoke and dust in its environment The smoke detection device is connected to the spray control system for spraying and dust reduction through the main controller; the spray control system is connected to the medicament configuration device for providing spray medicament through the medicament delivery device; The construction machinery is provided with a driver's cab control device for controlling the spray control system, the medicament delivery device and the medicament configuration device. By adopting the above-mentioned structure of the smoke elimination and dust reduction system, a large amount of dust, smoke, peculiar smell, etc. generated by excavation and transpo...

Embodiment 2

[0046] Any one of the smoke and dust reduction methods facing the smoke and dust reduction system in the centralized slag loading area is characterized in that it includes the following steps:

[0047] Step1: Move the walking construction machinery to the centralized slag loading area;

[0048] Step2: Start the smoke detection device, and operate the walking construction machinery to clean up the debris;

[0049] Step3: When the smoke and dust detection device detects the smoke and dust on the construction site, if there is only dust, the sprinkler control system will be activated and only water will be sprayed;

[0050] Step4: When the smoke detection device detects that the construction site contains harmful smoke and dust, start the agent dispensing device, and spray the mixed liquid containing the agent to eliminate the smoke and dust;

[0051] Step5: During the working process of the medicine dispensing device, the liquid level device 14 is used to observe the liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com