Intelligent disproportionated rosin potassium soap rubber additive blender and using method thereof

A disproportionated rosin potassium soap and rubber additive technology, which is applied in the field of intelligent disproportionated rosin potassium soap rubber additive mixer, can solve the problems of low work efficiency, long time for mixing, and high operating costs, so as to save labor, Effect of improving mixing efficiency and shortening working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

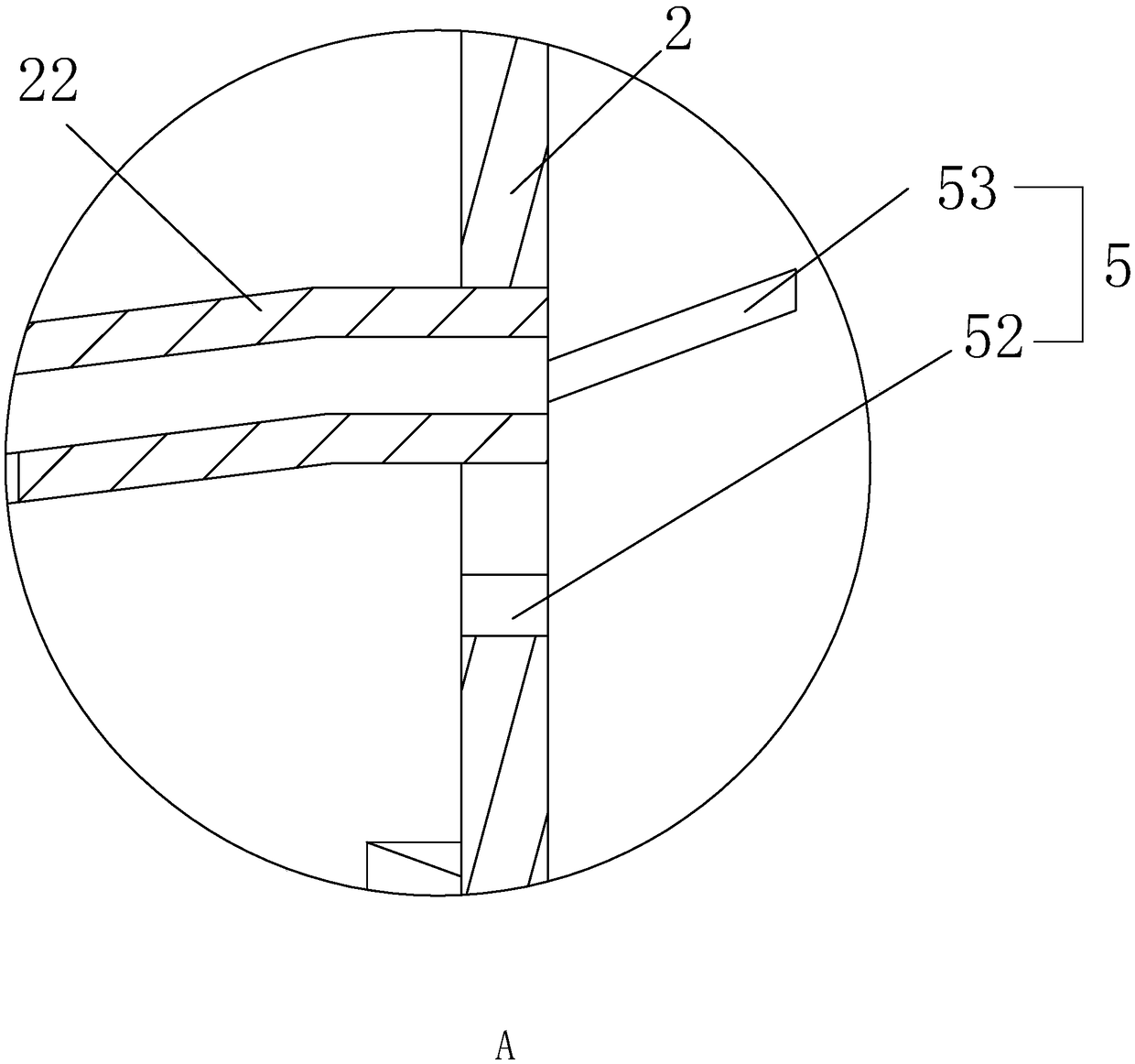

[0024] Embodiment: a kind of intelligent disproportionated rosin potassium soap rubber additive mixer, such as figure 1 As shown, it includes a barrel 1, the middle part of the barrel 1 is provided with a stirring shaft 2 controlled by a driving mechanism, and the barrel 1 has a feeding port 11 for feeding rubber materials and a driving motor 12 for controlling the rotation of the stirring shaft 2 .

[0025] like figure 1 As shown, at this time, a plurality of connecting bearings 21 are arranged on the outer peripheral surface of the stirring shaft 2 along its height direction array, and a plurality of partition plates 3 are arranged on the inside of the barrel 1 along its height direction array, so as to test the barrel 1 The inside is divided into a plurality of working space layers 6, and the outer ends of the partition 3 are respectively connected and fixed with the inner wall of the barrel 1, and at the same time, the outer ring of the connecting bearing 21 is fixedly co...

specific Embodiment approach

[0028] Specific embodiments: under normal conditions, the electromagnet 43 is not energized, and under the action of the limit block 44, the switch plate 42 is in a downward hanging state, and its end away from the hinge point communicates with the lower working space layer 6, through The feeding port 11 puts the rubber raw material into the barrel 1, and the rubber raw material first falls into the bottom working space layer 6 through the opening groove 41 on the upper partition 3, when a certain amount of rubber is stored in the bottom working space layer 6 raw material, and after the rubber raw material is in contact with the pressure sensor 45 on the bottom of the switch plate 42, the electromagnet 43 is triggered to work, to realize the adsorption of the switch plate 42, and to realize the closing of the opening slot 41 here, and then the rubber raw material can be stored on the upper layer. In the working space layer 6, according to this method, a large amount of rubber r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com