A powder recovery filter for a powder coating production line and its application method

A filter and production line technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of time-consuming and laborious manual cleaning, poor filtering effect, and easy dust accumulation of filter elements, so as to improve self-cleaning performance and reduce The accumulation of dust and the effect of ensuring the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

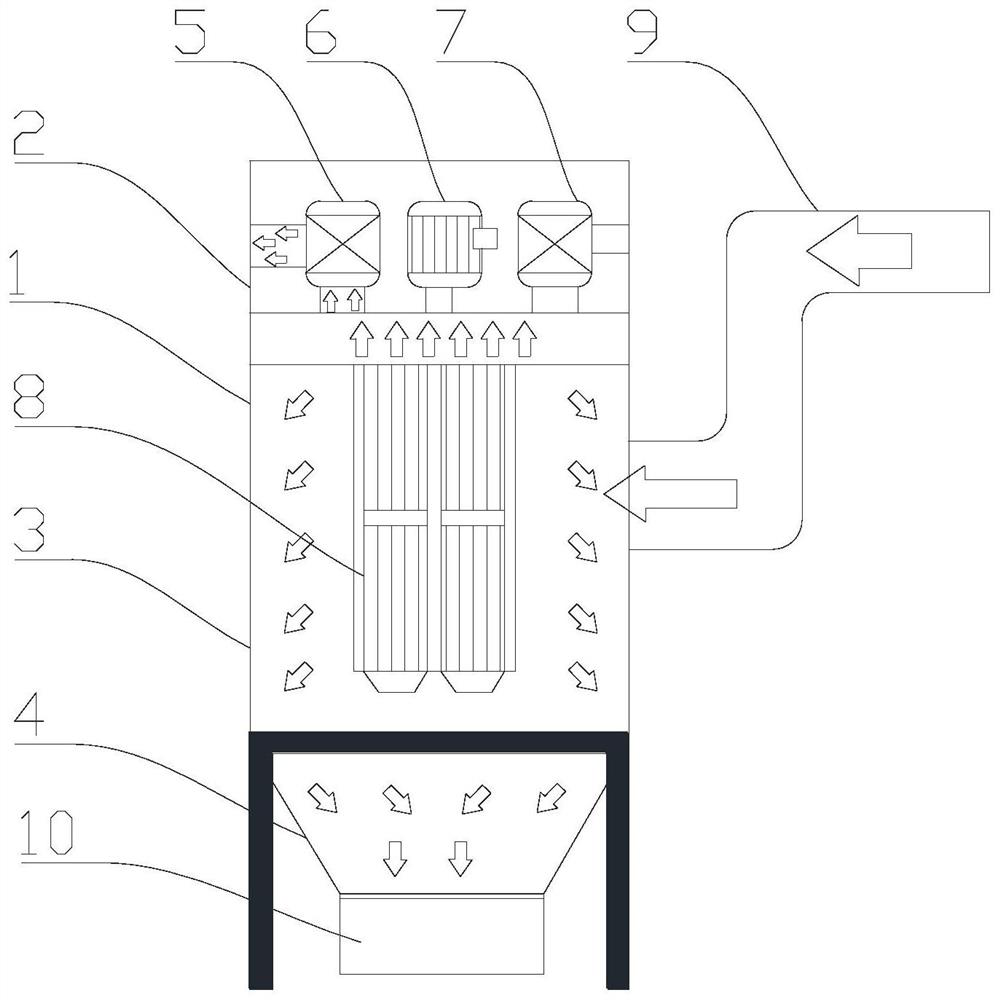

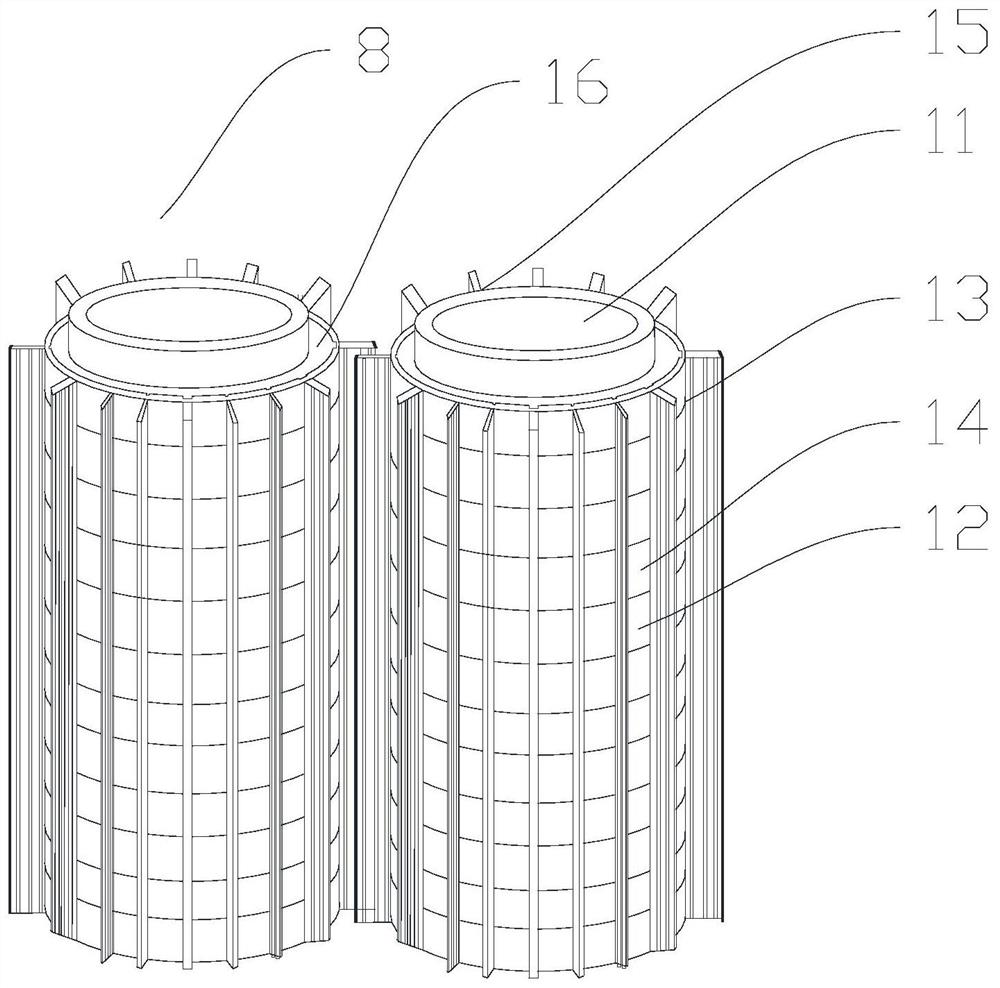

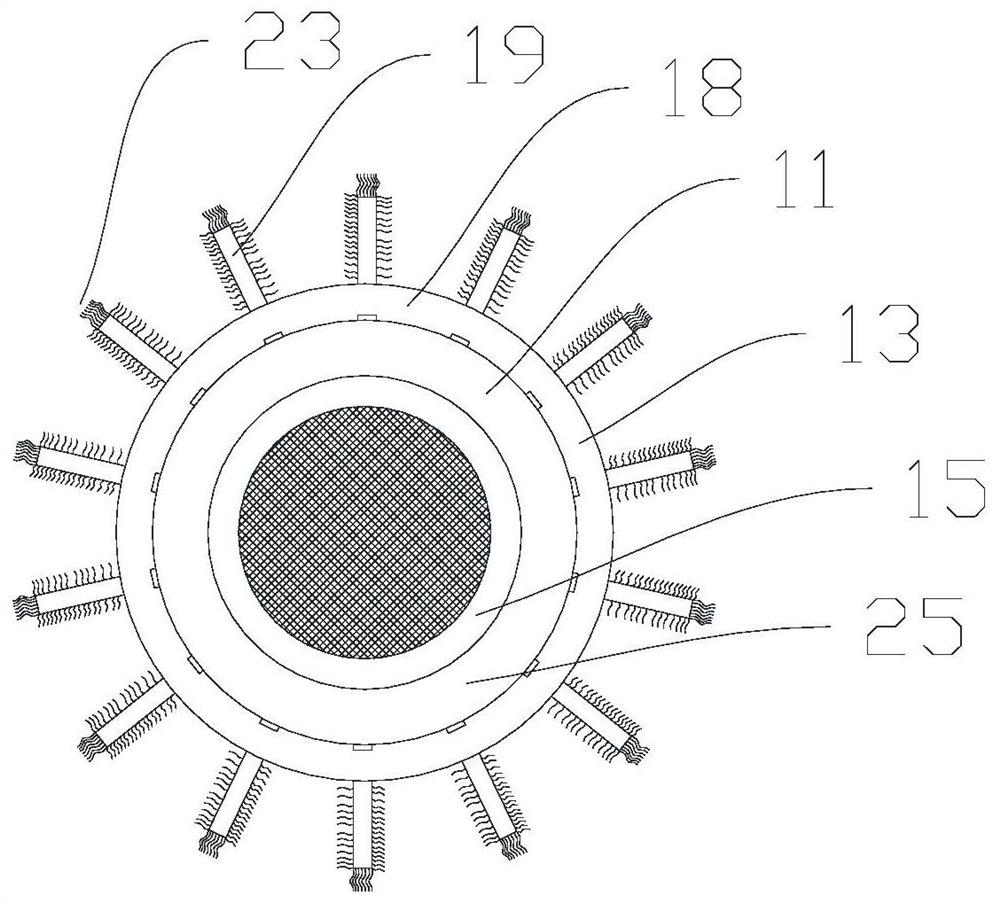

[0029] Such as Figure 1-6 In the shown embodiment, a powder recovery filter for a powder coating production line includes a filter body 1, and the filter body 1 includes an equipment layer 2, a filter layer 3, and a collection layer 4 from top to bottom. An air extractor 5, an electric motor 6, and an air compressor 7 are arranged inside the equipment layer 2, and a double filter element group 8 is arranged inside the filter layer 3, and the upper ends of the double filter element group 8 are connected through the rotation of the electric motor 6. On the upper end of the filter layer 3, an air intake duct 9 is also provided on the side of the filter layer 3, and the collection layer 4 is in the shape of an inverted truncated cone, the diameter of the upper end is the same as that of the filter layer 3, and the lower end is provided with There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com