Spinning punch transplanter

A transplanting machine and hole technology, which is applied to transplanting machinery, planting methods, excavation/covering trenches, etc., can solve the problems of low degree of automation, high labor intensity, inconvenient use, etc. High work efficiency and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

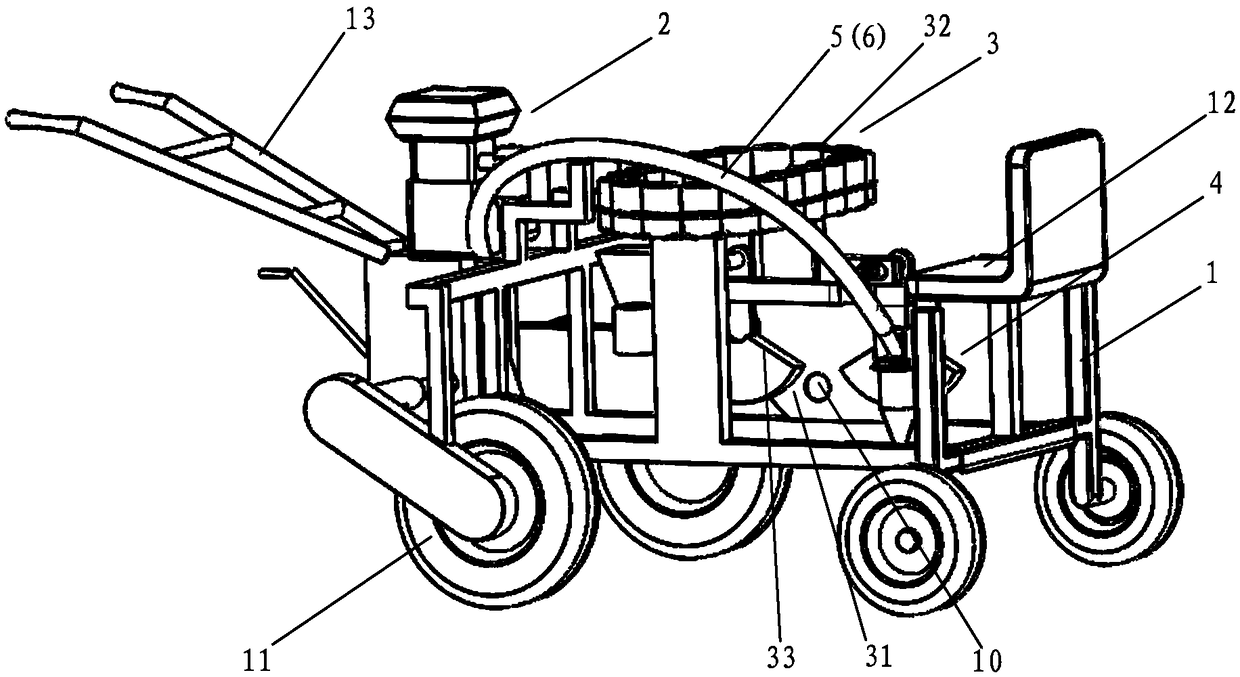

[0024] refer to Figure 1 to Figure 3 , the present embodiment relates to a transplanter, including a vehicle frame 1, a driving device 2, a seedling throwing device 3 and a hole-making device 4, and the driving device 2, the seedling throwing device 3 and the hole-making device 4 are installed on the vehicle frame 1, The bottom of the vehicle frame 1 is provided with a wheel 11, and the power output end of the driving device 2 is connected with the power input end of the wheel 11 and the punching device 4; People's seat 12, and the rear end of vehicle frame 1 is provided with the handle 13 that is used for manually pushing vehicle frame 1; The seedling throwing outlet 31 of described seedling throwing device 3 is corresponding to the bottom of punching device 4 and seedling 10 is thrown into In the cave hole punched out by the hole punching device 4.

[0025] When working, the seedling shooter sits on the seat 12, and the driver controls the traveling direction of the vehicl...

Embodiment 2

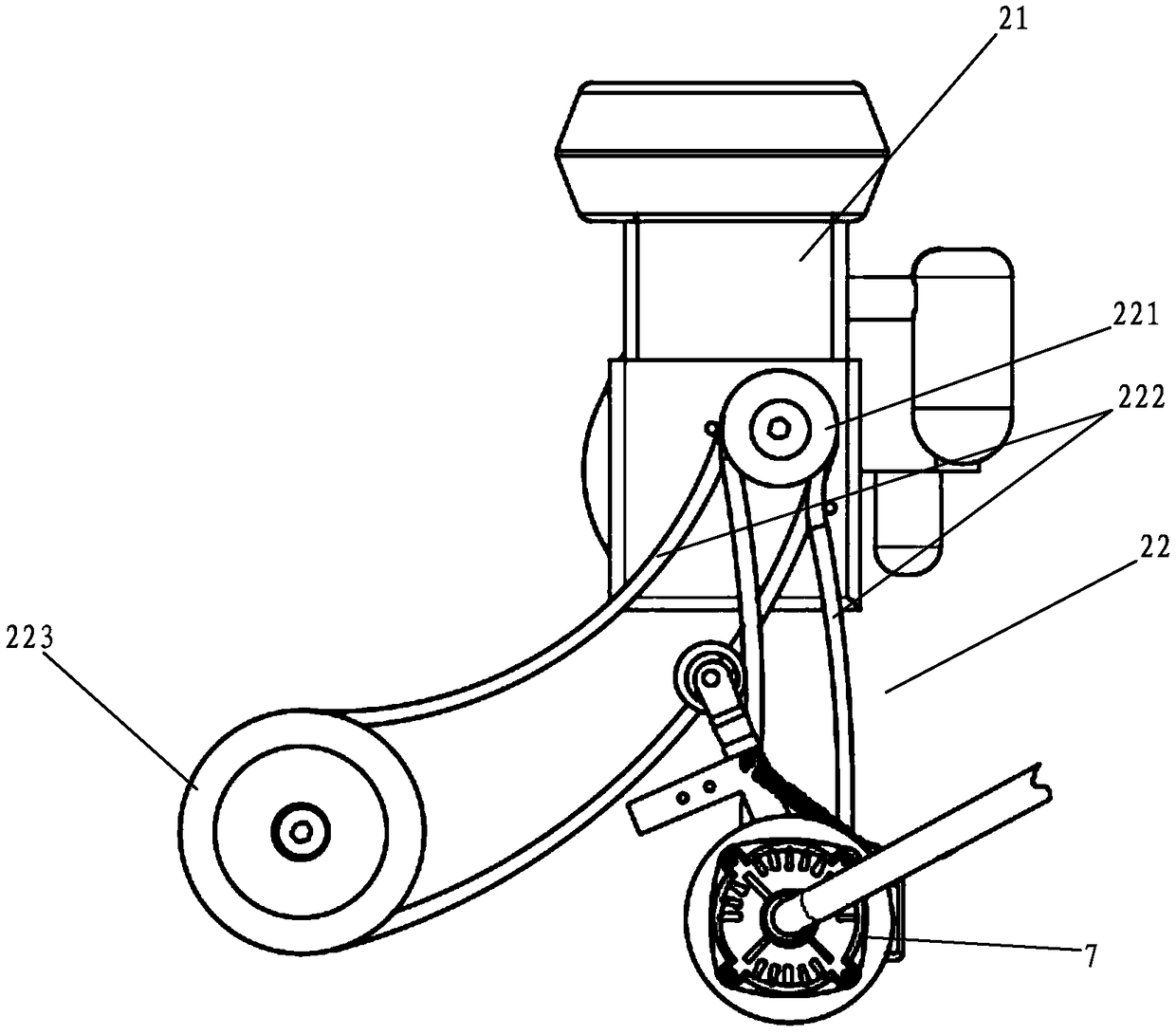

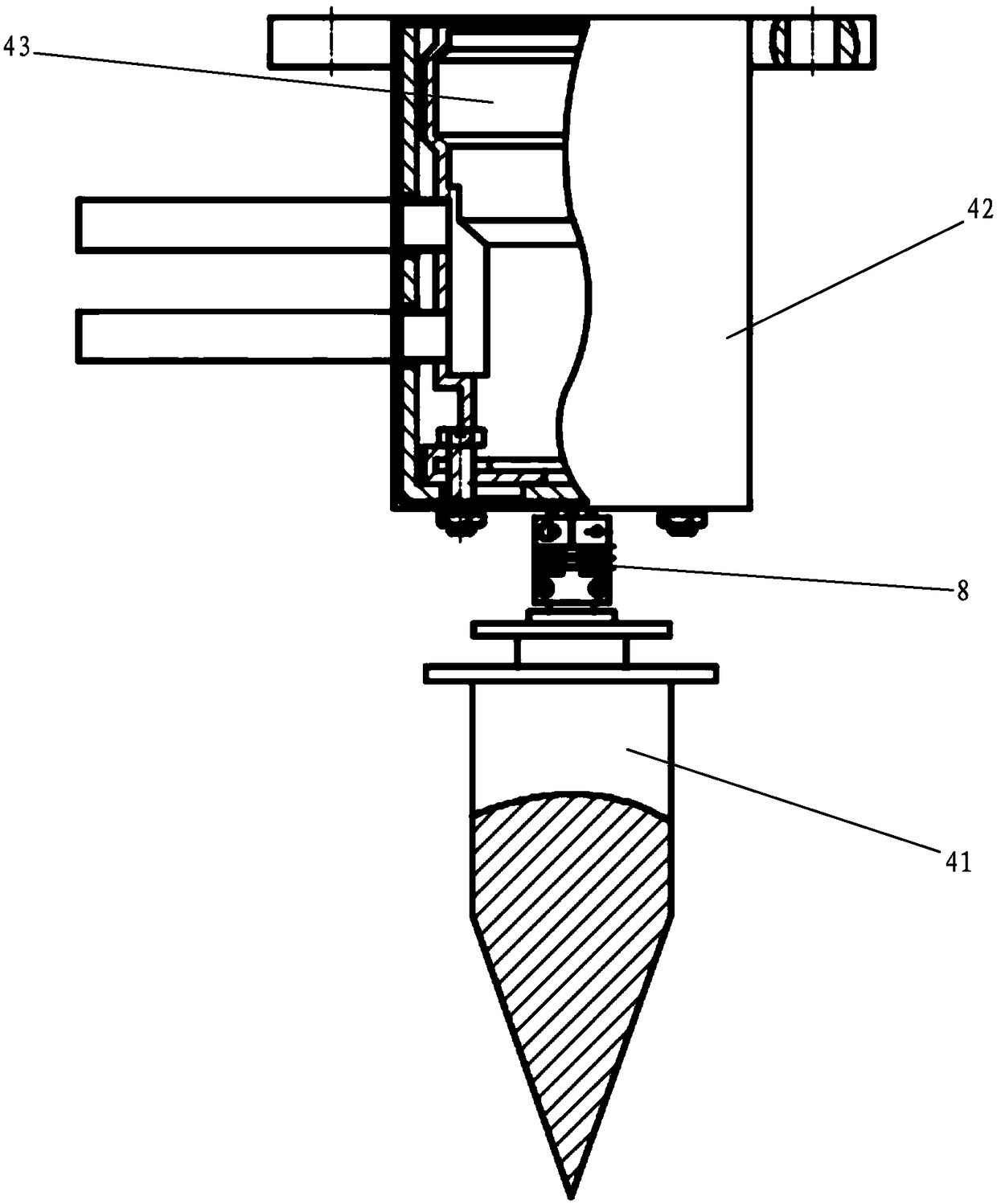

[0032]This embodiment is based on Embodiment 1, and as an improvement to the punching device 4, the punching device 4 includes a mounting base 42, a hydraulic motor 43 and a punching head 41, and the mounting base 42 is installed on the vehicle frame 1, the hydraulic motor 43 is installed on the mounting base 42, and the hydraulic motor 43 is connected to the power output end of the driving device 2 through the pipeline 6 and the hydraulic pump 7, and the acupuncture head 41 is fixed to the output shaft of the hydraulic motor 43 connect. When working, the engine 21 drives the hydraulic pump 7 to work through the transmission mechanism 22, so that the hydraulic pump 7 outputs hydraulic oil to the hydraulic motor 43 and drives the hydraulic motor 43 to drive the acupuncture head 41 to rotate.

[0033] In order to facilitate the connection between the acupuncture head 41 and the hydraulic motor 43 , the acupuncture head 41 is fixedly connected to the output end of the hydraulic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com