Halogen-free fire retardant coating capable of forming a barrier layer and use thereof

A technology of fire retardant coating and barrier layer, applied in the direction of coating, can solve problems such as poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

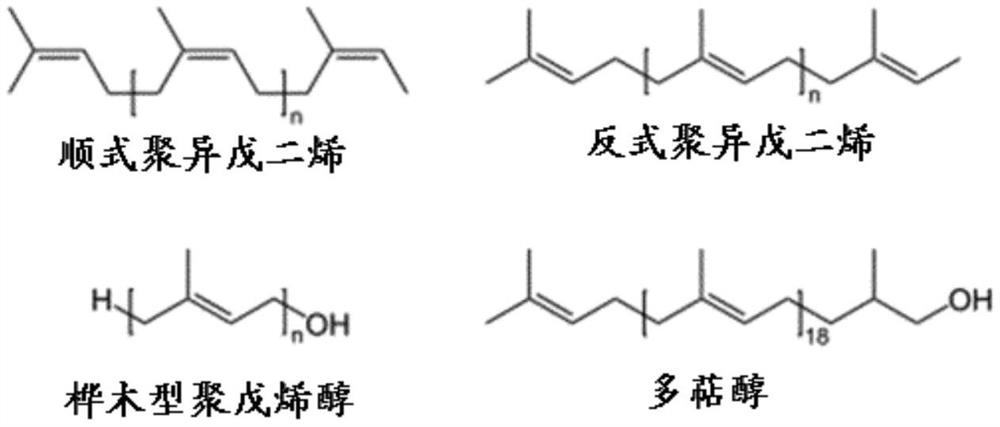

Method used

Image

Examples

Embodiment 1

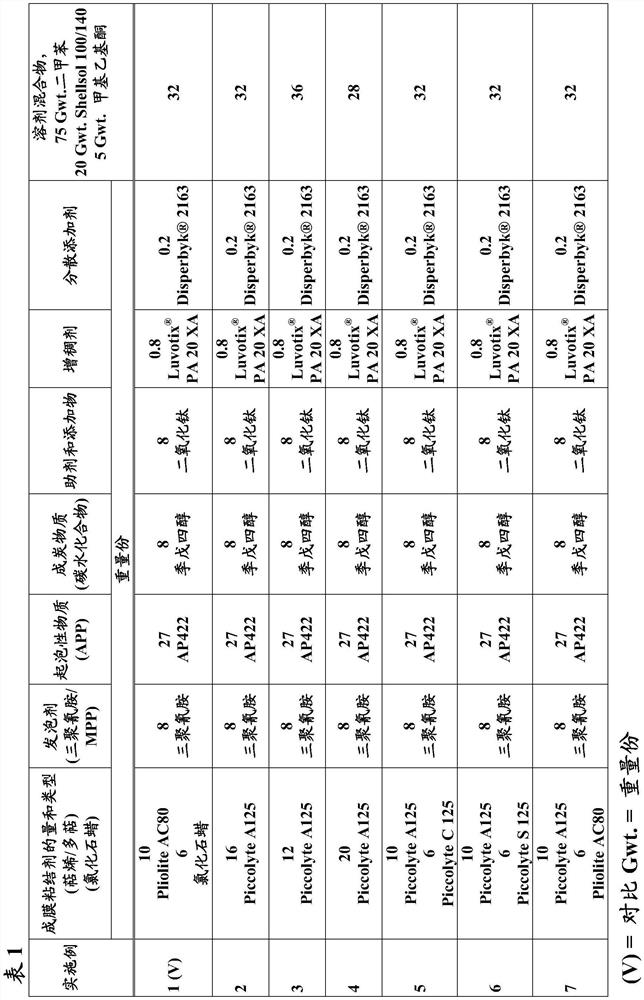

[0138] Embodiment 1 (comparison)

[0139] 27 parts by weight AP 422

[0140] 10 parts by weight AC 80

[0141] 6 parts by weight of chlorinated paraffin

[0142] 8 parts by weight of melamine

[0143] 8 parts by weight of pentaerythritol

[0144] Auxiliaries and additives, thickeners, dispersing additives and solvents are added according to Table 1 up to 100 parts by weight.

Embodiment 2

[0146] 27 parts by weight AP 422

[0147] 16 parts by weight A125

[0148] 8 parts by weight of melamine

[0149] 8 parts by weight of pentaerythritol

[0150] Auxiliaries and additives, thickeners, dispersing additives and solvents according to Table 1 to 100 parts by weight.

Embodiment 3

[0152] 27 parts by weight AP 422

[0153] 12 parts by weight A125

[0154] 8 parts by weight of melamine

[0155] 8 parts by weight of pentaerythritol

[0156] Auxiliaries and additives, thickeners, dispersing additives and solvents according to Table 1 to 100 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com