Lining model used for shield tunnel longitudinal model test and manufacturing method thereof

A technology of shield tunneling and model testing, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as large differences, and achieve the effect of improving reliability, good mechanical behavior and deformation law

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing:

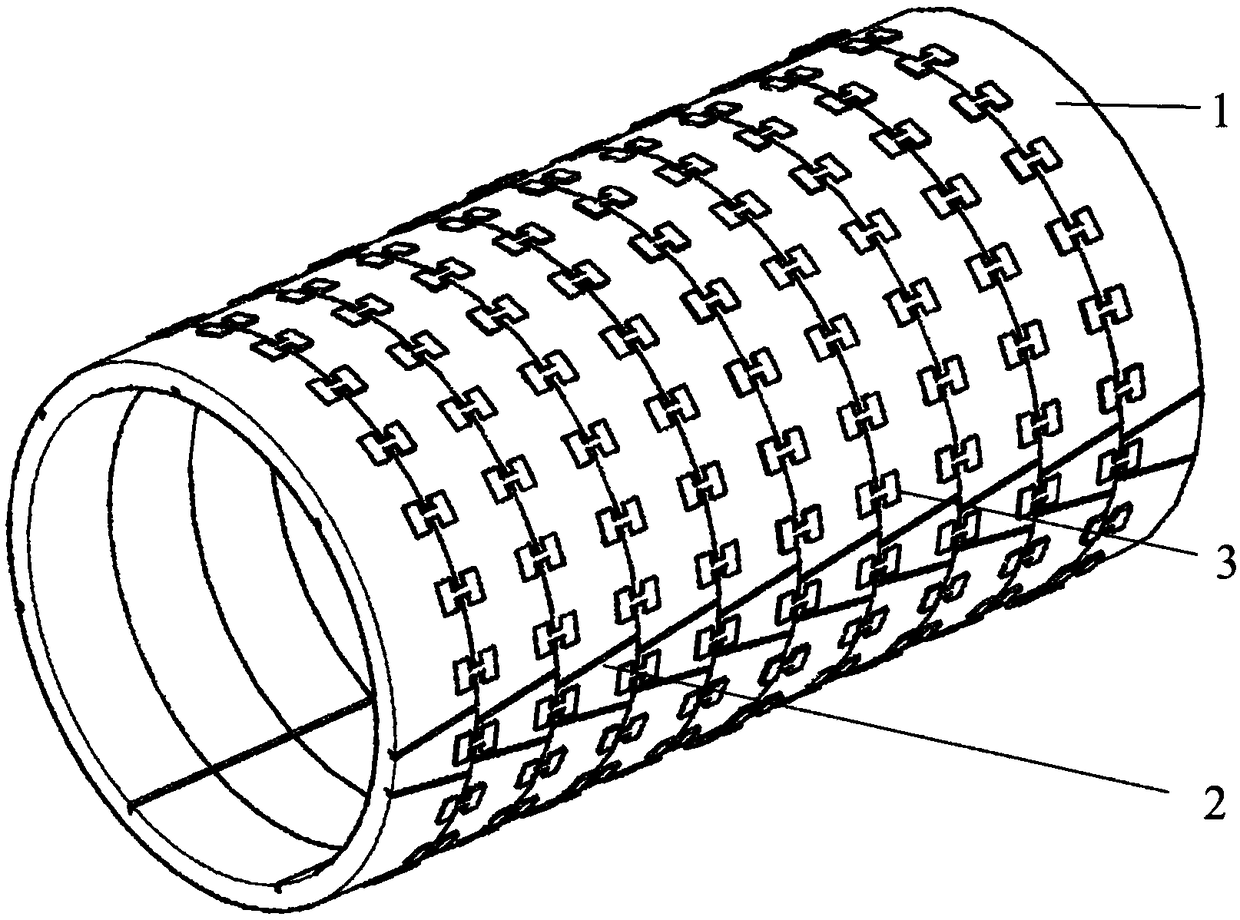

[0049] Such as figure 1 As shown in , it is a schematic diagram of the staggered splicing structure of the segmental lining model.

[0050] The present invention provides a segment lining model for the longitudinal model test of shield tunnel, which comprises a plurality of segment rings 1 spliced with each other, and cut grooves 2 are opened on the sides of the segment rings 1, such as figure 2 As shown, the cutting grooves 2 are respectively opened on the inner side wall and the outer side wall of the segment ring 1, and the positions of the cutting grooves 2 correspond to the positions of the transverse joints on the original lining segment structure.

[0051] A longitudinal joint piece 3 is evenly glued on the outer wall of the adjacent segment ring 1, such as image 3 As shown, the longitudinal joint 3 is I-shaped, and the flanges 31 at both ends of the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com