A kind of preparation method of curved liquid crystal material

A liquid crystal material, bending technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of high nematic phase transition temperature, narrow nematic phase temperature range, limited application and development of materials, etc., and achieve low nematic phase. Phase inversion temperature, effect of wide nematic temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

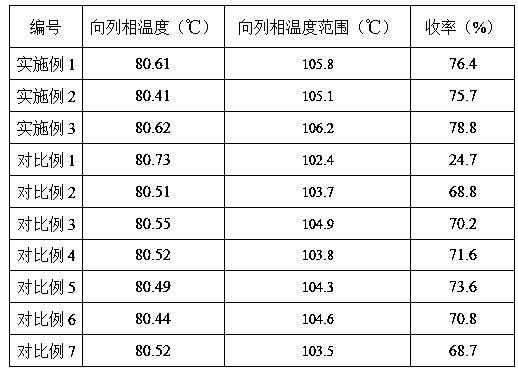

Examples

Embodiment 1

[0018] A method for preparing a curved liquid crystal material, the preparation technical scheme is as follows:

[0019] In terms of parts by mass, 24.5 parts of 2,5-bis(p-hydroxyphenyl)-1,3,4-oxadiazole, 88 parts of intermediates, 45 parts of N,N-dicyclohexylcarbodiethylene Amine, 6.5 parts of N,N-lutidine, 0.3 parts of 1,3-diiminoisoindoline, 0.7 parts of N,N'-bis(4-pyridyl)naphthalene tetracarbonyl di Imine, 0.02 parts of soybean oil ethyl morpholinium ethosulfate, 0.02 parts of tetrabutylammonium hexachloroplatinate, and 350 parts of dichloromethane were added to the thoroughly dried reaction kettle, and then Vacuumize, then replace the air in the reactor with high-purity nitrogen, and finally fill it with high-purity nitrogen for protection; then react at room temperature for 24 hours; then filter, evaporate the total solvent of the filtrate to dryness, and add 180 parts of The solvent is heated to 55° C. to dissolve, stirred for 25 minutes, cooled down to recrystallize,...

Embodiment 2

[0025] A method for preparing a curved liquid crystal material, the preparation technical scheme is as follows:

[0026] In terms of parts by mass, 23.5 parts of 2,5-bis(p-hydroxyphenyl)-1,3,4-oxadiazole, 85 parts of intermediates, 42 parts of N,N-dicyclohexylcarbodiethylene Amine, 6.8 parts of N,N-lutidine, 0.1 part of 1,3-diiminoisoindoline, 0.1 part of N,N'-bis(4-pyridyl)naphthalene tetracarbonyl di Imine, 0.01 part of soybean oil ethyl morpholinium ethosulfate, 0.01 part of tetrabutylammonium hexachloroplatinate, and 300 parts of dichloromethane were added to the thoroughly dried reaction kettle, and then Vacuumize, then replace the air in the reactor with high-purity nitrogen, and finally fill it with high-purity nitrogen for protection; then react at room temperature for 28 hours; then filter, evaporate the total solvent of the filtrate to dryness, and add 200 parts of The solvent is heated to 60° C. to dissolve, stirred for 30 minutes, cooled down to recrystallize, fil...

Embodiment 3

[0032] A method for preparing a curved liquid crystal material, the preparation technical scheme is as follows:

[0033] In terms of parts by mass, 26.5 parts of 2,5-bis(p-hydroxyphenyl)-1,3,4-oxadiazole, 91 parts of intermediates, 48 parts of N,N-dicyclohexylcarbodia Amine, 6.8 parts of N,N-lutidine, 0.5 parts of 1,3-diiminoisoindoline, 1 part of N,N'-bis(4-pyridyl)naphthalene tetracarbonyl di Imine, 0.06 part of soybean oil ethyl morpholinium ethosulfate, 0.05 part of tetrabutylammonium hexachloroplatinate, and 400 parts of dichloromethane join in the reaction kettle of thorough drying, then Vacuumize, then replace the air in the reactor with high-purity nitrogen, and finally fill it with high-purity nitrogen for protection; then react at room temperature for 28 hours; then filter, evaporate the total solvent of the filtrate to dryness, and add 200 parts of The solvent is heated to 60° C. to dissolve, stirred for 30 minutes, cooled down for recrystallization, filtered, wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com