A kind of heteropoly acid salt solid catalyst and its preparation method and application

A technology of solid catalyst and heteropoly acid salt, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, etc. It can solve the problems of poor catalytic performance and achieve good stability, high yield and good catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

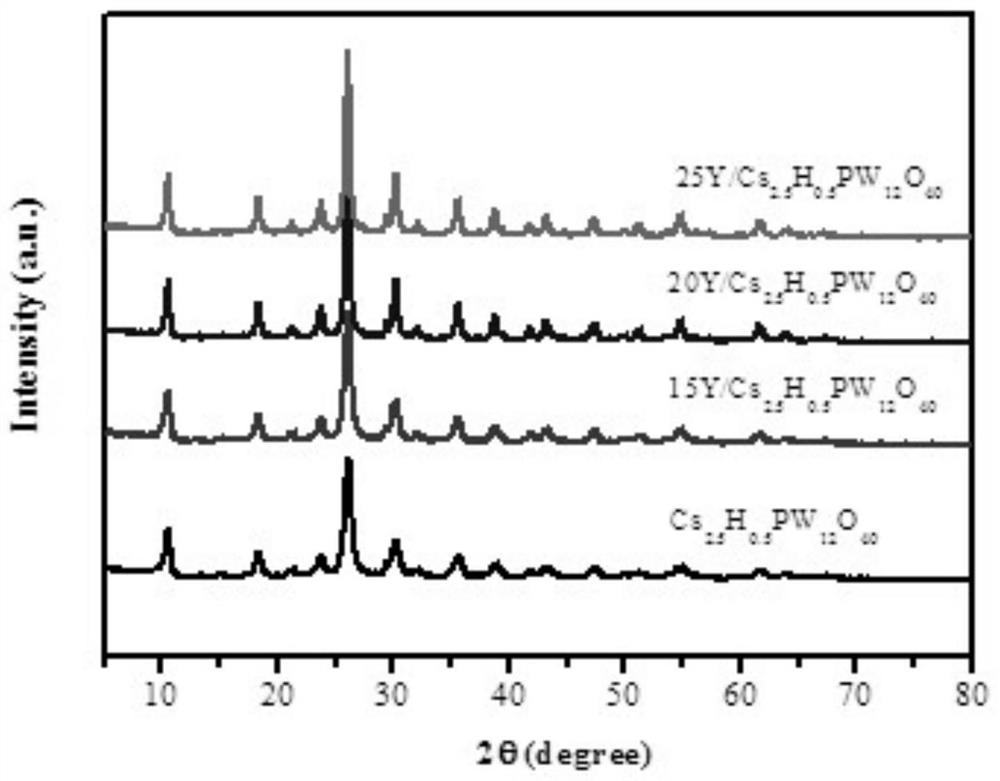

[0046] Preparation of Y / Cs x h 3-x PW 12 o 40 (the scope of x is 0.5~3.0) catalyzer, its step is as follows:

[0047] 1. Preparation of acid carrier cesium phosphotungstate: at 50°C, 0.1697g Cs 2 CO 3 Dissolve in 20mL of water, then Cs 2 CO 3 The aqueous solution was added dropwise to 1 g of phosphotungstic acid (H 3 PW 12 o 40 ) in an aqueous solution, a white precipitate was obtained, which was continued to be stirred at 50°C for 12h, dried overnight at 120°C to obtain a white solid, and calcined at 400°C for 2h to prepare Cs 3 PW 12 o 40 ;

[0048] At 50°C, 0.1414g Cs 2 CO 3 Dissolve in 20mL of water, then Cs 2 CO 3 The aqueous solution was added dropwise to 1 g of phosphotungstic acid (H 3 PW 12 o 40 ) in an aqueous solution, a white precipitate was obtained, which was continued to be stirred at 50°C for 12h, dried overnight at 120°C to obtain a white solid, and calcined at 400°C for 2h to prepare Cs 2.5 h 0.5 PW 12 o 40 ;

[0049] At 50°C, 0.1131g ...

Embodiment 2

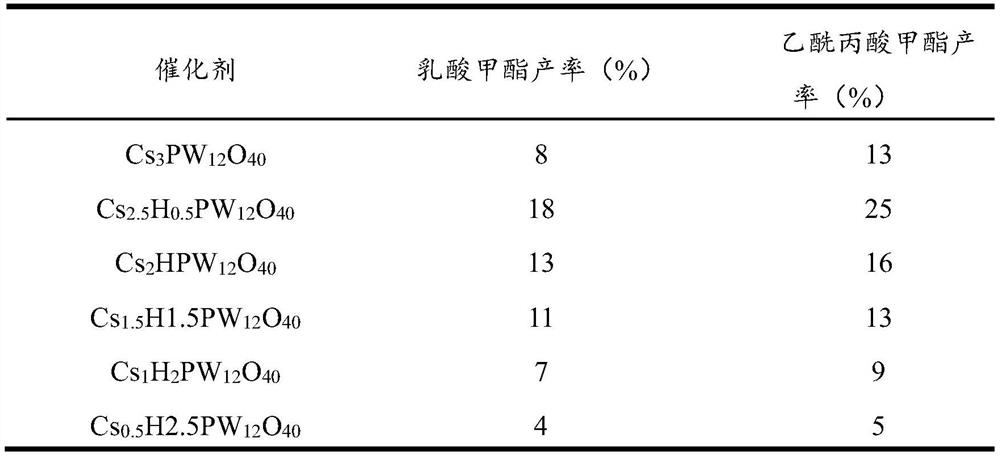

[0057] A series of Cs prepared by step 1 of Example 1 x h 3-x PW 12 o 40 (The range of x is 0.5~3.0) The catalyst catalyzes the production of methyl lactate from cellulose:

[0058] Weigh 0.15g cellulose, 0.1g Cs x h 3-x PW 12 o 40 (The scope of x is 0.5~3.0) catalyzer, 11.76g methyl alcohol, 0.24g water are in 25mL stainless steel autoclave, pass into the air in nitrogen replacement autoclave under room temperature, repeat three times, then pass into the nitrogen of 2MPa, in Under 600rpm stirring condition, 220 ℃ of reaction 8h, centrifugation catalyst is separated after reaction finishes, and after reaction solution is filtered with 0.22 μm microporous membrane, calculate the productive rate of methyl lactate with high performance liquid chromatography, the result is shown in Table 1.

[0059] As can be seen from Table 1, the Cs prepared in Step 1 of Example 1 of the present invention 2.5 h 0.5 PW 12 o 40 The catalyst cellulose has the highest yield of methyl lact...

Embodiment 3

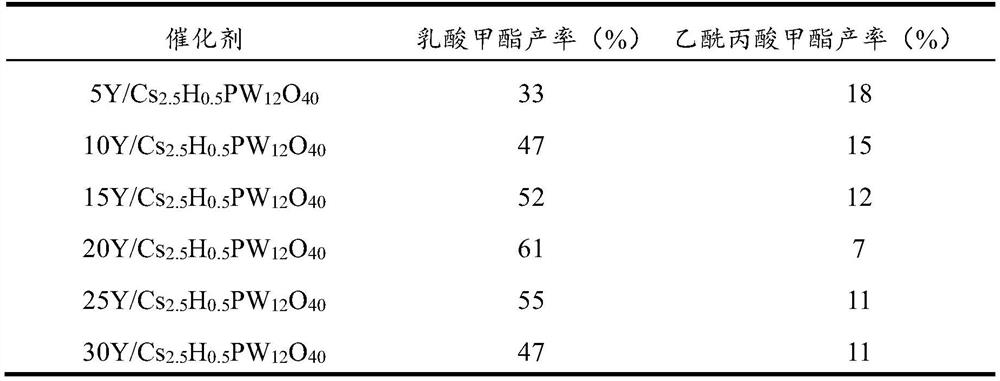

[0063] Utilize the Y / Cs of a series of different Y loads prepared in embodiment 1 step 2 2.5 h 0.5 PW 12 o 40 The catalyst catalyzes the production of methyl lactate from cellulose:

[0064] Weigh 0.15g cellulose, 0.1g Y / Cs 2.5 h 0.5 PW 12 o 40 Catalyst, 11.76g methyl alcohol, 0.24g water are in 25mL stainless steel autoclave, pass into the air in the autoclave of nitrogen replacement under room temperature, repeat three times, then pass into the nitrogen of 2MPa, under the stirring condition of 600 rpm, 220 ℃ for 8 hours. After the reaction, the catalyst was centrifuged. After the reaction solution was filtered with a 0.22 μm microporous membrane, the productive rate of lactic acid was measured and calculated by high performance liquid chromatography. The results are shown in Table 2.

[0065] As can be seen from Table 2, the Y / Cs of different Y loadings prepared in Step 2 of Example 1 of the present invention 2.5 h 0.5 PW 12 o 40 The average ratio of the catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com