Agricultural fertilizer spreader

A spreader and agricultural technology, applied in the field of agricultural machinery, can solve the problems of fertilizer waste, turning to mobile fertilization, failure, etc., and achieve the effects of reducing interference to movement, scientific and reasonable structure, and safe and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

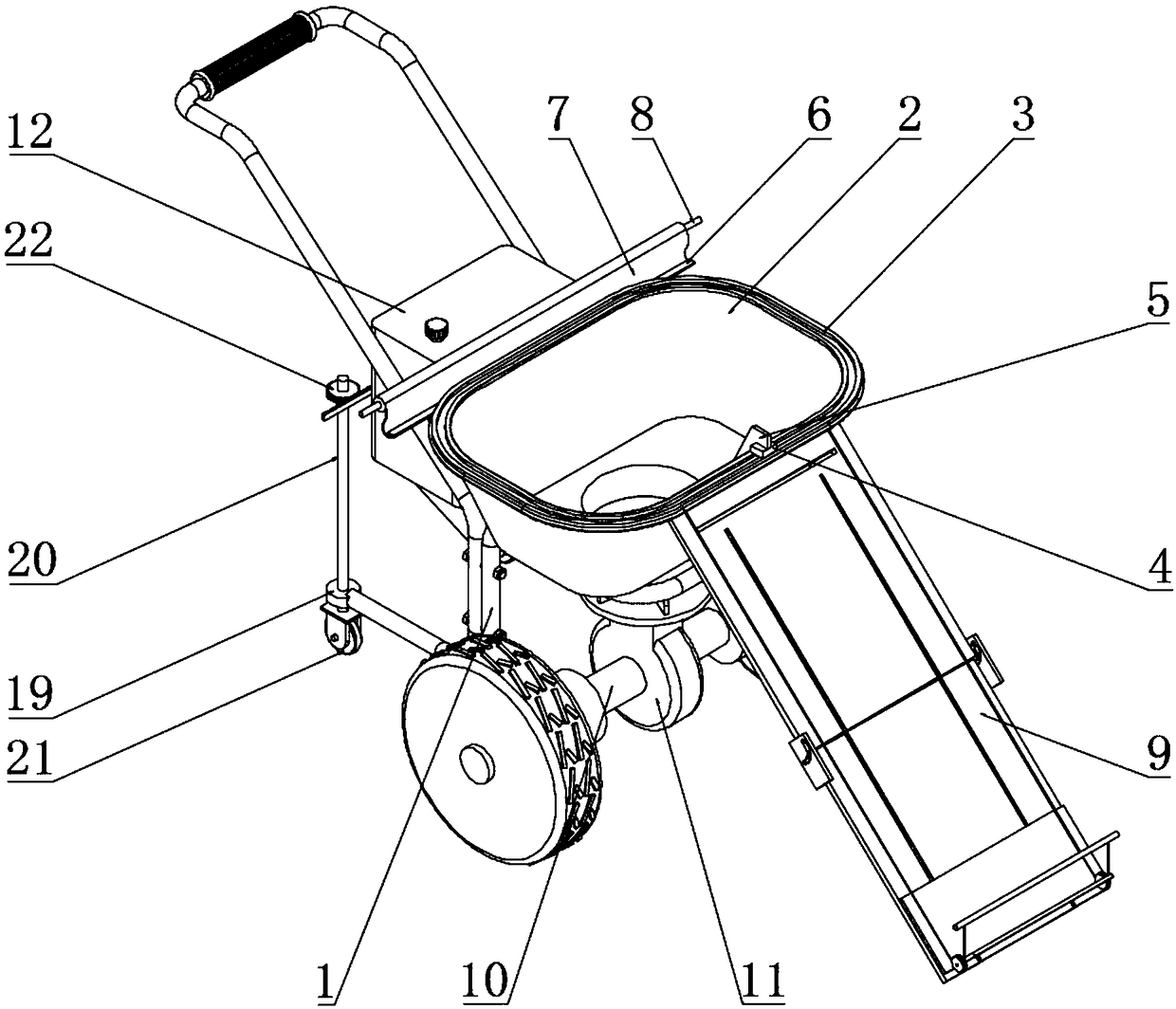

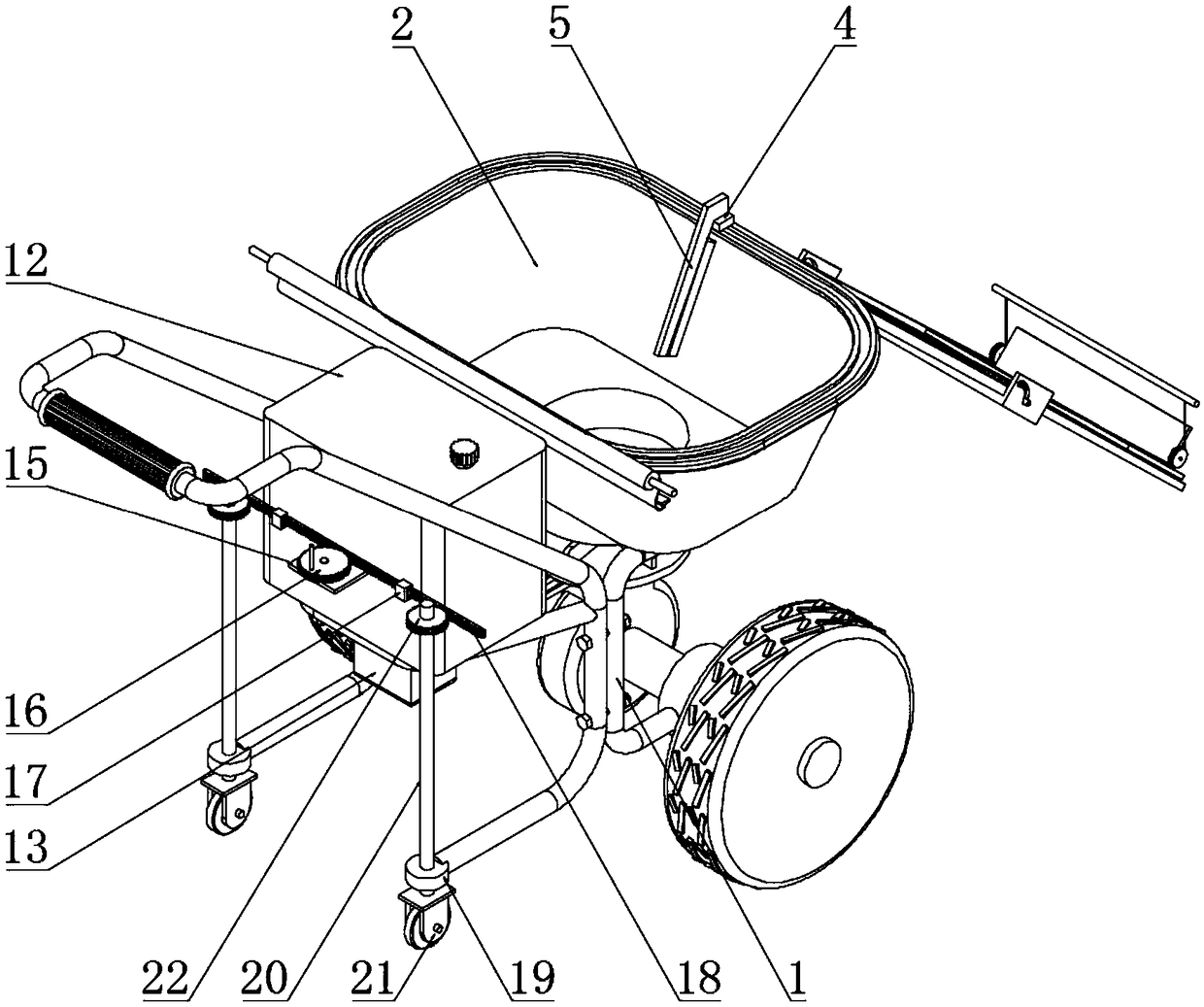

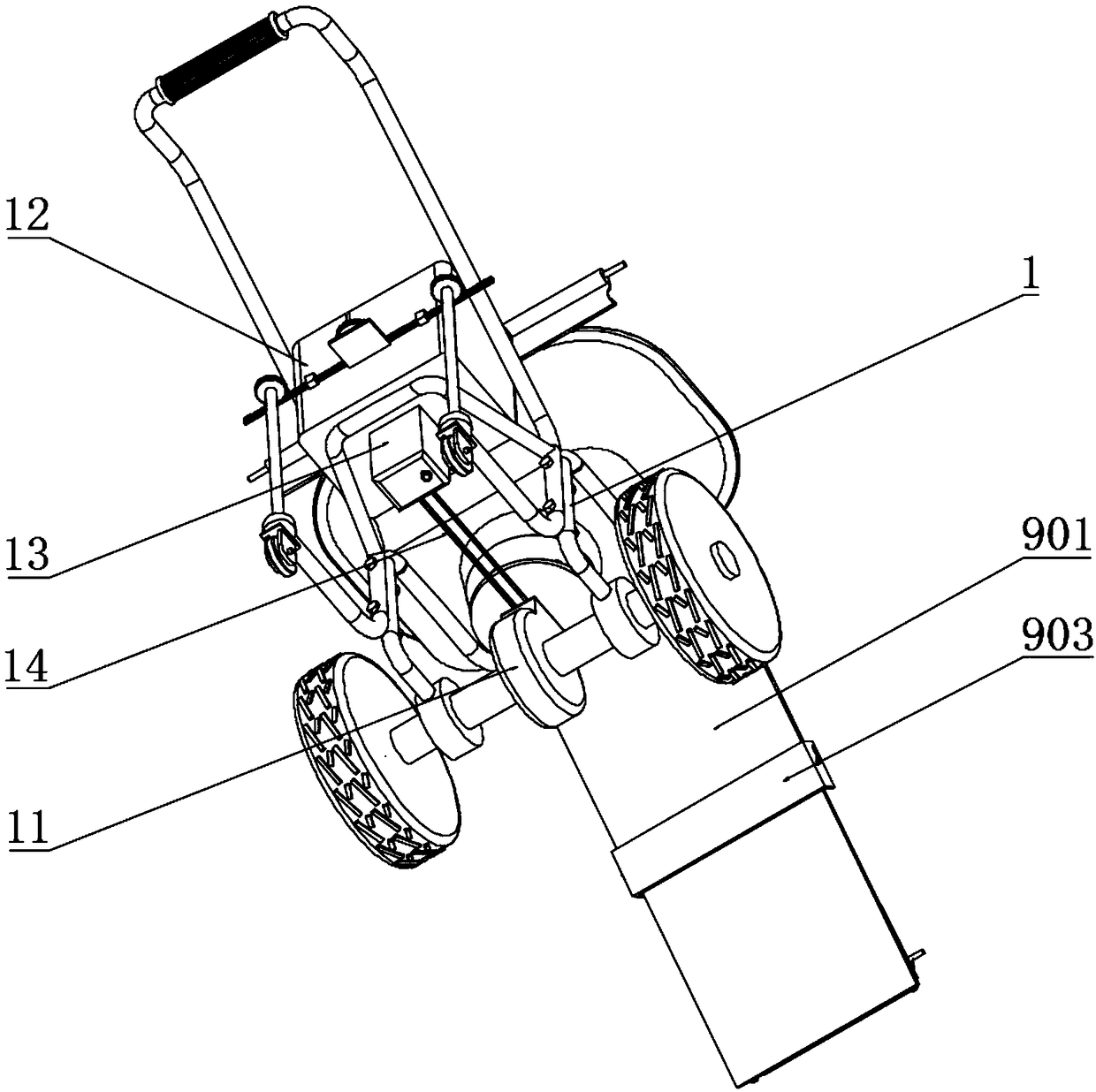

[0030] Example: such as Figure 1-7As shown, the present invention provides a technical solution, an agricultural fertilizer spreader, comprising a spreader body 1, a funnel 2 is installed above the spreader body 1, a slide rail 3 is installed on the top of the funnel 2, and the slide rail 3 A slider 4 is installed above, and a scraper mechanism 5 is installed on one side of the slider 4. The scraper mechanism 5 includes a mounting plate 501, a scraper 502, a spring receiving hole 503, an adjustment spring 504, a limit hole 505 and a limit post 506 , a scraper 502 is installed on one side of the mounting plate 501, and a spring storage hole 503 is evenly opened on the opposite side of the scraper 502 and the mounting plate 501, and an adjustment spring 504 is installed inside the spring storage hole 503, and the spring storage on the mounting plate 501 A limiting hole 505 is set inside the hole 503, and a limiting column 506 is installed inside the spring receiving hole 503 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com