PCB patch adhesive dispensing device

A patch and glue dispensing technology, which is applied in the direction of electrical components, printed circuit manufacturing, electrical components, etc., can solve the problems of small application range and achieve the effects of wide application range, vibration damping shafting dynamic performance, and avoiding operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

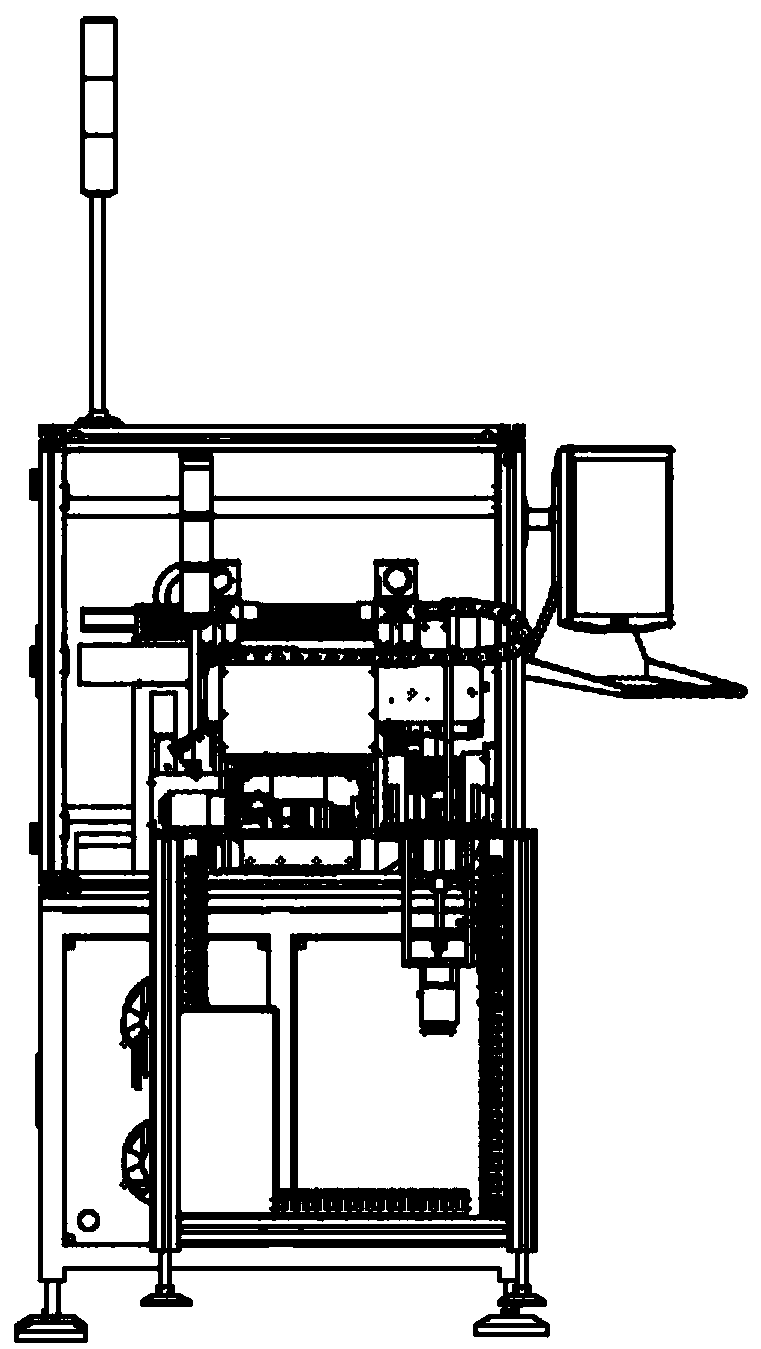

[0108] Such as figure 1 , Figure 4 , Figure 17 Shown, a kind of PCB patch glue dispensing equipment comprises frame one 1, SMT patch characteristic mechanism 2, frame two 3, electric control cabinet 4, operation panel 5 and PCB glue dispensing mechanism 6; Described SMT patch The characteristic mechanism 2 is divided into a PCB feeding conveyor mechanism 20 and an SMT placement mechanism 21; the PCB dispensing mechanism 6 includes an adjustment conveying mechanism 60 and a glue dispensing mechanism 61; this equipment is controlled by PLC, and the control panel buttons are manually operated. The PCB circuit board conveying line is designed as an adjustable conveying line mechanism with adjustable spacing, and the ball screw is driven by a synchronous motor, which overcomes the problem that the PCB patch dispensing equipment in the prior art can only be used for a fixed size PCB workpiece For the technical problem of processing, the distance of the conveying line can be adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com