Photovoltaic power generation system with self-cleaning function

A photovoltaic power generation system and self-cleaning technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of difficulty in guaranteeing the cleaning rate, reducing power generation efficiency, and affecting the use of photovoltaic power generation systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

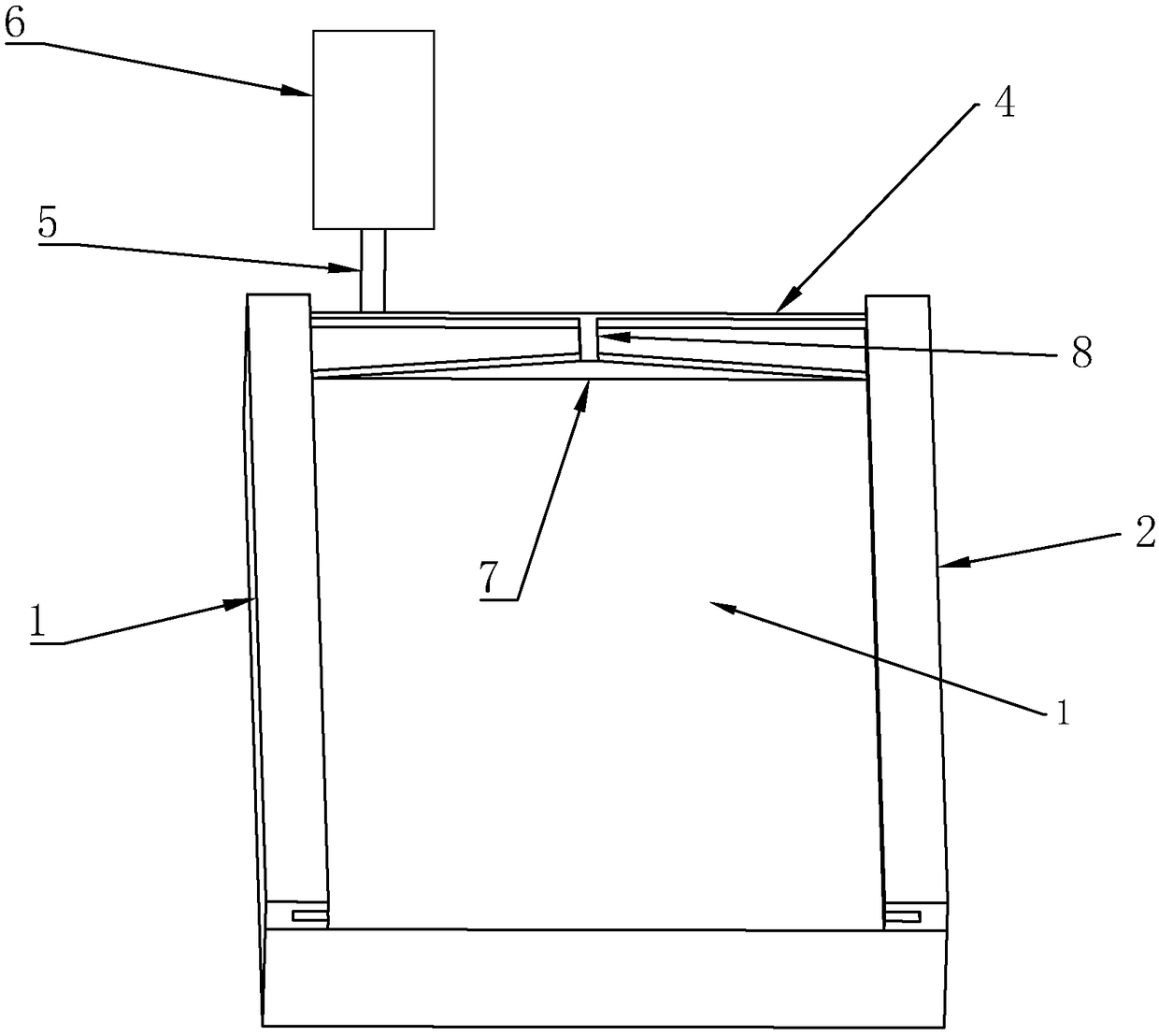

[0021] refer to Figure 1 to Figure 2 An embodiment of a photovoltaic power generation system with self-cleaning function of the present invention will be further described.

[0022] A photovoltaic power generation system with a self-cleaning function, including a photovoltaic panel 1, a bottom plate and a support rod, the photovoltaic panel 1 is installed obliquely on a support frame, the bottom plate is connected to the photovoltaic panel 1 through a support rod, and the support frame includes a second A bracket and a second bracket, the first bracket and the second bracket are connected through a connecting piece, and also include a self-cleaning device that can move by itself, and the self-cleaning device includes

[0023] sprinkler mechanism for spraying water,

[0024] A cleaning mechanism for cleaning the surface of the photovoltaic panel 1,

[0025] drive mechanism for powering the water spray mechanism and the cleaning mechanism,

[0026] The drive mechanism includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com