Environmental-friendly cable recycling method

A recycling method and an environmentally friendly technology, applied in the field of electric power engineering, can solve the problems of high manpower consumption, low processing effect or processing efficiency, and low degree of intelligence, so as to achieve efficient cable recycling and avoid secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

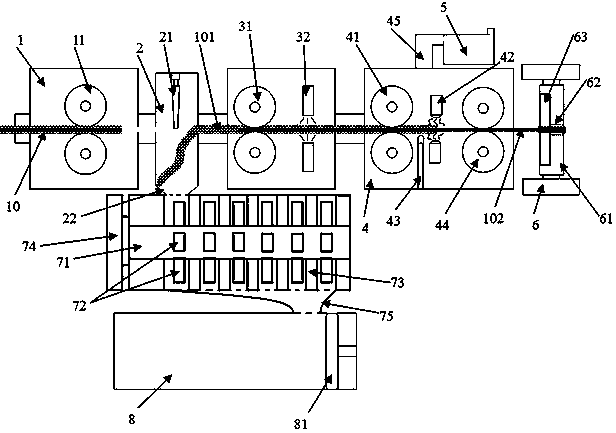

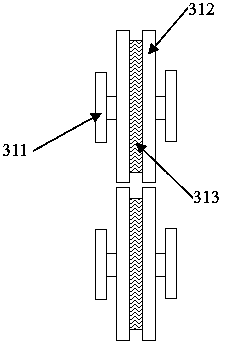

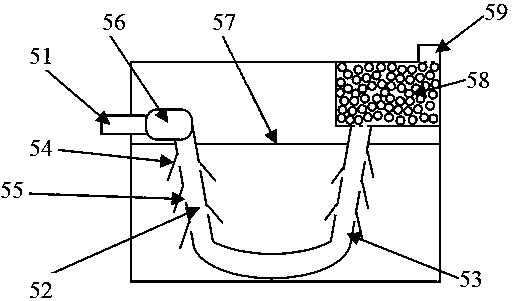

[0038] Such as Figure 1-3 As shown, an environment-friendly cable recovery method, the method adopts an environment-friendly cable recovery device, and the environment-friendly cable recovery device includes a transmission room, a cable skin treatment room, a preheating room, a peeling room, a core material winding roller, a smoke Gas treatment chamber, crushing chamber and cable sheath collection chamber.

[0039] The transmission chamber, the cable sheath processing chamber, the preheating chamber, the peeling chamber and the core material winding roller are arranged in sequence.

[0040] The transfer chamber includes a transfer chamber casing, a transfer chamber inlet, a transfer chamber outlet and a first transfer roller, the transfer chamber inlet and the transfer chamber outlet are horizontally arranged on two opposite sides of the transfer chamber casing, and the first transfer roller It includes two turning rollers arranged up and down opposite to each other, and is ...

Embodiment 2

[0060] An environment-friendly cable recovery method, the method adopts an environment-friendly cable recovery device, and the environment-friendly cable recovery device includes a transmission room, a cable sheath treatment room, a preheating room, a peeling room, a core material winding roller, and a flue gas treatment room , crushing chamber and cable sheath collection chamber.

[0061] The transmission chamber, the cable sheath processing chamber, the preheating chamber, the peeling chamber and the core material winding roller are arranged in sequence.

[0062] The transfer chamber includes a transfer chamber casing, a transfer chamber inlet, a transfer chamber outlet and a first transfer roller, the transfer chamber inlet and the transfer chamber outlet are horizontally arranged on two opposite sides of the transfer chamber casing, and the first transfer roller It includes two turning rollers arranged up and down opposite to each other, and is used to horizontally transpo...

Embodiment 3

[0082] An environment-friendly cable recovery device, which includes a transmission room, a cable sheath treatment room, a preheating room, a peeling room, a core material winding roller, a flue gas treatment room, a crushing room and a cable sheath collection room.

[0083] The transmission chamber, the cable sheath processing chamber, the preheating chamber, the peeling chamber and the core material winding roller are arranged in sequence.

[0084] The transfer chamber includes a transfer chamber casing, a transfer chamber inlet, a transfer chamber outlet and a first transfer roller, the transfer chamber inlet and the transfer chamber outlet are horizontally arranged on two opposite sides of the transfer chamber casing, and the first transfer roller It includes two turning rollers arranged up and down opposite to each other, and is used to horizontally transport waste cables from the entrance of the transmission chamber to the exit of the transmission chamber.

[0085] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com