Intelligent stepless proportioning implementation method

A realization method and pulp mixing technology, applied in non-electric variable control, instrument, control/regulation system, etc., can solve the problems of easy forgery, high cost, unstable quality of manual pulp mixing, etc. The effect of mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

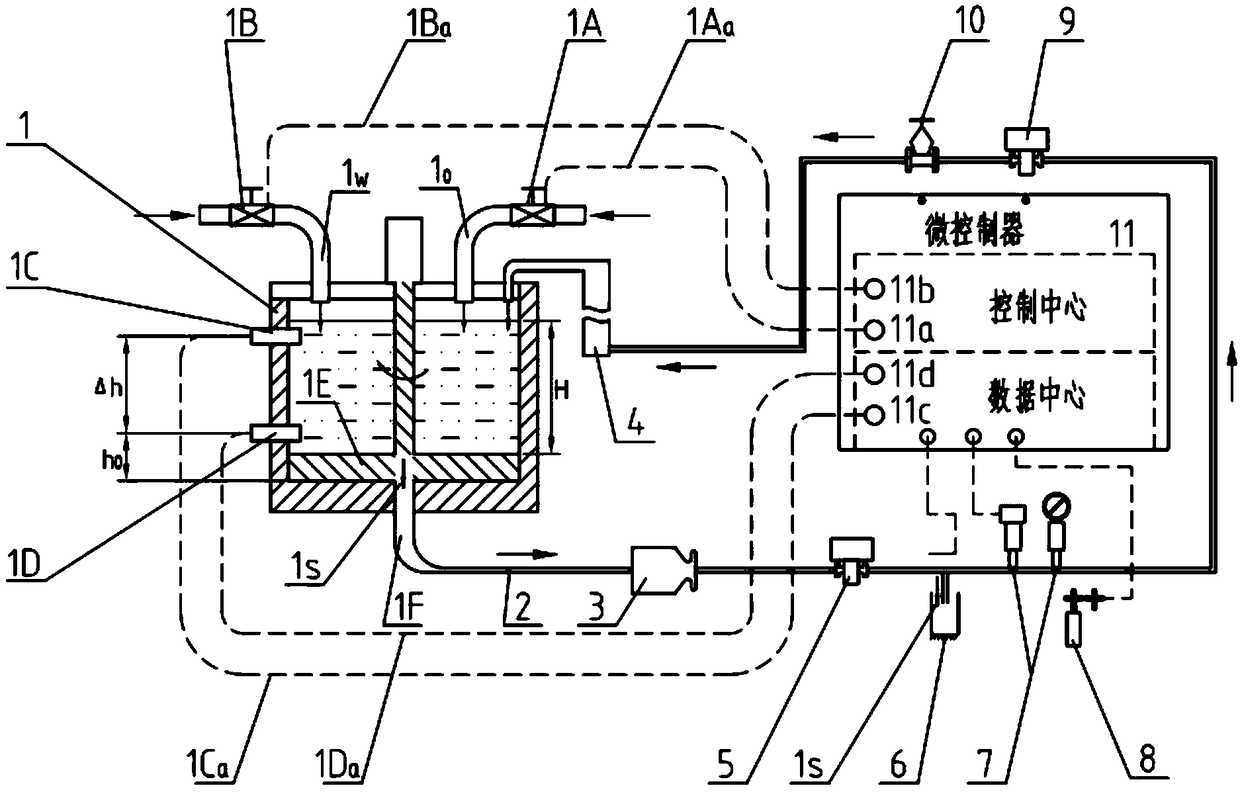

[0028] See figure 1 , the implementation method of intelligent stepless grouting in this embodiment. First, this grouting method is realized in the existing grouting circuit. The grouting circuit at least includes: the grouting barrel 1 is connected to the grouting pump sequentially by the pipeline 2 from the grouting outlet 1F below. 3. Slurry inlet flow sensor 5, grouting hole 6, orifice pressure sensor 7, lifting sensor 8, return slurry flow sensor 9, pressure regulating valve 10, density sensor return slurry density bucket 4, and finally connect the pulping from the upper entrance Bucket; forms an existing basic grout circulation loop for the flow of grout. The pulp 1s prepared from raw pulp 1o and clear water 1w in the pulping tank 1 is discharged to the grouting hole 6 through the pulping outlet 1F, and the remaining recirculation is returned to the pulping tank 1 by the return pulp density tank 4 .

[0029] The implementation method of intelligent stepless pulp mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com