Rapid prototyping device for special-shaped sheet metal parts

A technology for forming devices and sheet metal parts, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor sheet metal forming quality and high manual labor intensity, and achieve low processing efficiency, reduce labor intensity, and improve The effect on labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

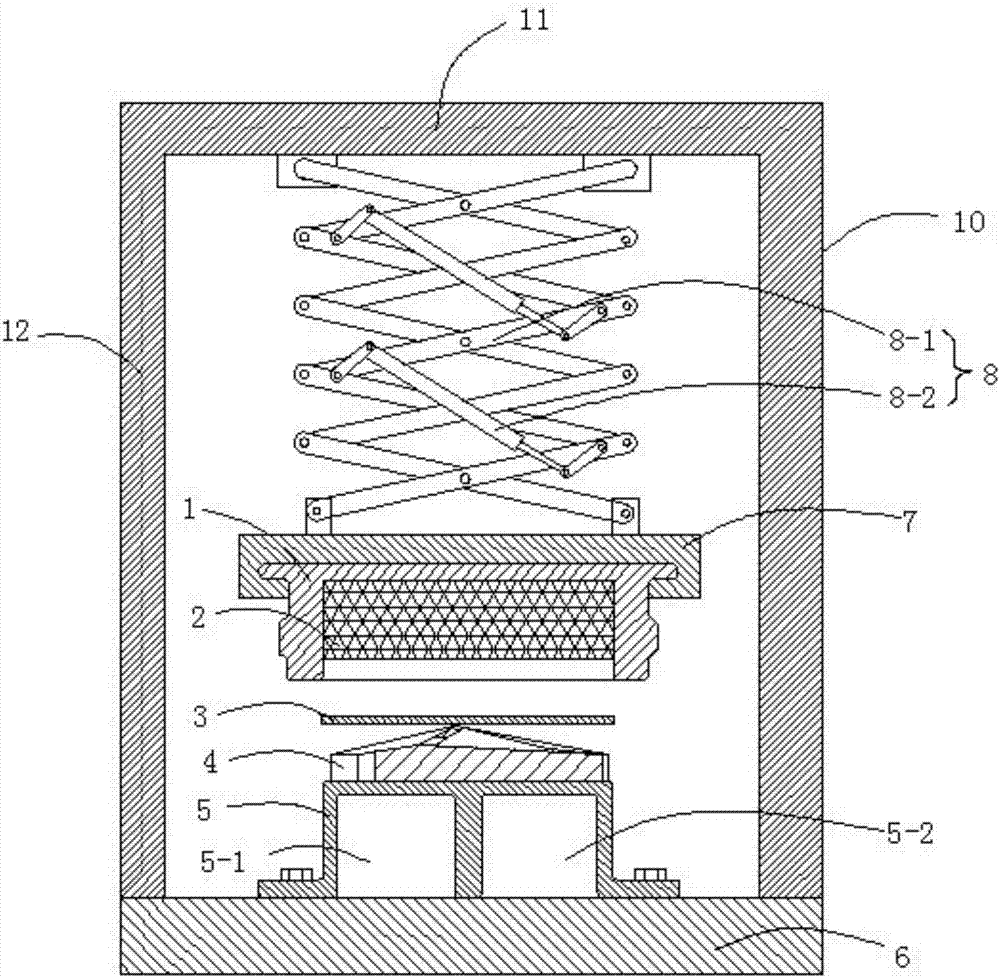

[0025] like Figures 1 to 3 As shown, this embodiment provides a rapid prototyping device for special-shaped sheet metal parts, including an upper mold base 7, a die 1 clamped in the upper mold base 7, a lower mold base 6, and a die base fixed on the lower mold base 6 and the die 1 A matching forming support punch 5, characterized in that the concave mold 1 is a semi-closed cavity concave mold, a rubber plate 2 is arranged in the semi-closed cavity of the concave mold 1, and the thickness of the rubber plate 2 is smaller than that of the semi-closed cavity The depth of the molding support punch 5 is fixedly provided with a molded workpiece film tire 4 for supporting the workpiece 3 to be processed, and the upper mold base 7 is provided with a pressure type lifting mechanism.

[0026] In this embodiment, the mold structure is simple, the processing efficiency can be improved, and the production time can be greatly saved. The most important thing is that the device can be insta...

Embodiment 2

[0028] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0029] The pressure-type lifting mechanism includes a left vertical support plate 12 and a right vertical support plate 10 installed at the left and right ends of the lower mold base 6, and a connecting horizontal support plate 12 and the right vertical support plate 10 are connected between the left vertical support plate 12 and the right vertical support plate 10 The plate 11 is connected with a lifting assembly 8 under the horizontal plate 11. The lower end of the lifting assembly 8 is connected with the upper end of the upper mold base 7, and the lifting assembly 8 is a cutting-type lifting mechanism.

[0030] The lifting assembly 8 includes a scissors support 8-1 and a plurality of hydraulic cylinders 8-2 installed on the scissors support 8-1.

[0031] The scissors support 8-1 includes a plurality of X-shaped scissors connected end-to-end from top to bottom, two adjacent X-shaped sci...

Embodiment 3

[0034] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically:

[0035] The forming support punch 5 is provided with a weight reducing chamber A5-1 and a weight reducing chamber B5-2.

[0036] The sum of the maximum thickness of the molded workpiece film tire 4 and the thickness of the rubber plate 2 is less than the depth of the semi-closed cavity.

[0037] The left and right sides of the upper end of the concave die 1 are provided with clamping grooves 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com