Rotary force transfer assembly, roller and processing box

A technology of rotational force transmission and rotational force, which is applied in the directions of electrography, optics, instruments, etc., and can solve the problems of unsmooth connection and disengagement process, complicated connection structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

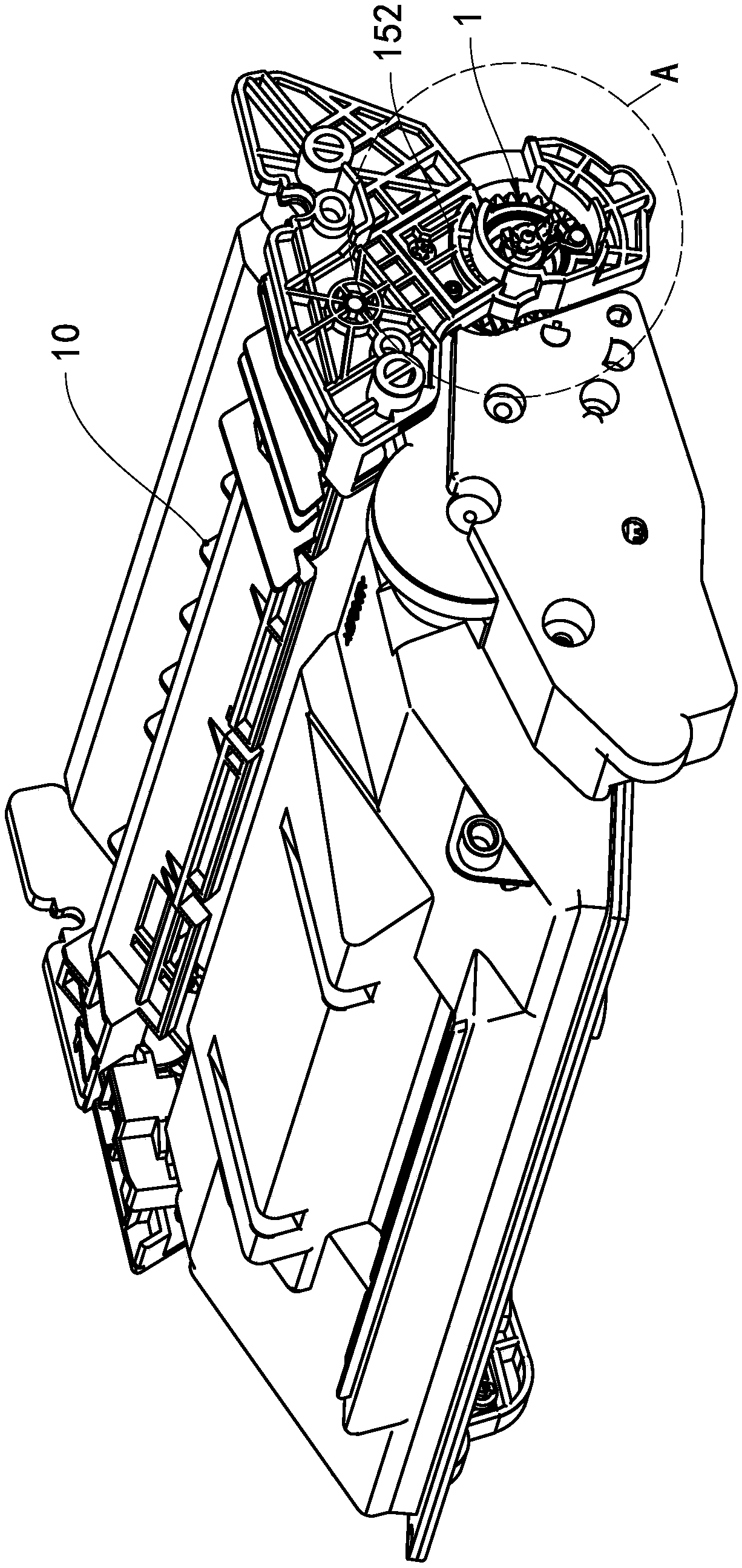

[0068] The first embodiment of the process box

[0069] See figure 1 The process box of this embodiment includes a box body 10 and a roller rotatably supported between the two end walls of the box body 10. The roller includes a roller body and a rotational force transmission assembly 1 installed at one axial end of the roller body. The roller in this embodiment is a photosensitive drum. In other embodiments, the roller may also be a developing roller or a powder feed roller. The rotational force transmission assembly 1 is used to communicate with the transmission shaft 100 of the printer ( Image 6 Show) connected to receive rotational force, and transmit the received rotational force to the drum and other rotating parts.

[0070] See Figure 2 to Figure 4 , The rotational force transmission assembly 1 includes a transmission gear 11, a rotational force receiving head 12, a jack mechanism 13, a rotational force transmission member 14, a rotation angle limiting assembly 15 and an ax...

Example

[0114] Fourth embodiment of process box

[0115] As a description of the fourth embodiment of the process cartridge of the present invention, only the differences from the second embodiment of the above-mentioned process cartridge will be described below.

[0116] See Figure 21 In this embodiment, the rotational force transmission assembly 4 further includes the driving mechanism 37 in the third embodiment of the process cartridge.

[0117] In this embodiment, the ejector rod self-rotating force receiving head 42 extends into the photosensitive drum and extends from the end of the photosensitive drum away from the rotational force transmission assembly 4. The ejector rod 431 includes a rod portion 4311 and a rod portion 4311 located away from the rotation. The ground pin 4312 at one end of the force transmission assembly 4. The structure of the ground pin 4312 is the same as that of the ground pin 3312 in the third embodiment of the process cartridge.

[0118] The rod 4311 is provid...

Example

[0119] The fifth embodiment of the process box

[0120] As a description of the fifth embodiment of the process cartridge of the present invention, only the differences from the first embodiment of the above-mentioned process cartridge will be described below.

[0121] See Figure 22 to Figure 24 In this embodiment, the rotational force transmission assembly 5 further includes a drive mechanism 57, the drive mechanism 57 is installed on the end cover of the box body close to the rotational force transmission assembly 5, and the drive mechanism 57 is connected to the top rod 531 and is connected to the force receiving part 5310 applies force.

[0122] The driving mechanism includes a shift lever 571 and a rotating shaft 572. The shift lever 571 is hinged on the end cover through the rotating shaft 572, and the shift lever 571 is arranged perpendicular to the top rod 531. The lever 571 includes a force end 5711 and a force end 5712. The force end 5711 receives the force of the printe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com