A rotary hob for environment-friendly and energy-saving combustion equipment

A combustion equipment and rotary furnace technology, applied in the direction of combustion equipment, combustion type, combustion method, etc., can solve the problems of complex composition of combustible waste, difficulty in operation and maintenance, difficulty in ash and slag removal, etc., to achieve easy ash and slag removal, Easy operation and maintenance, low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and wherein a specific embodiment:

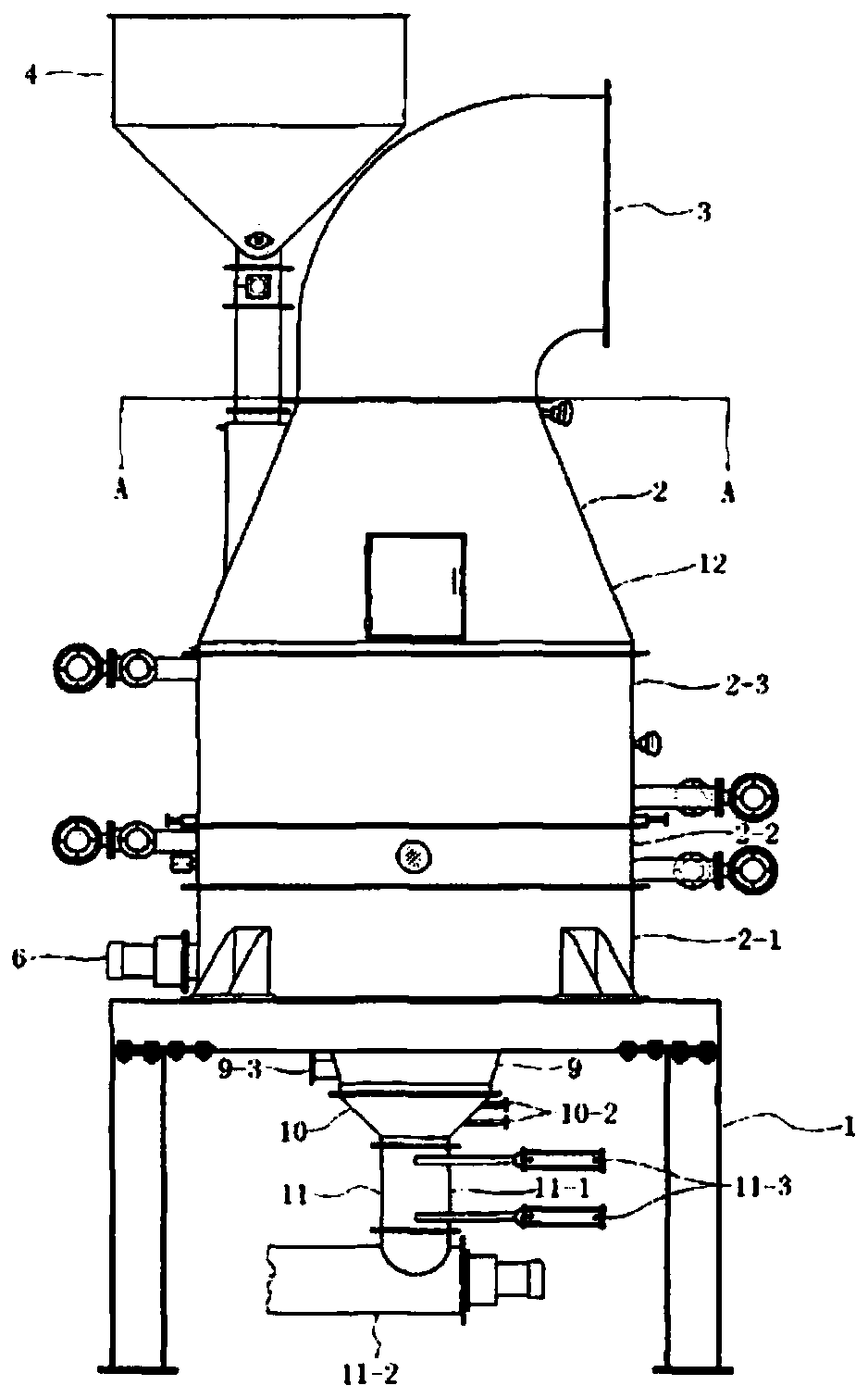

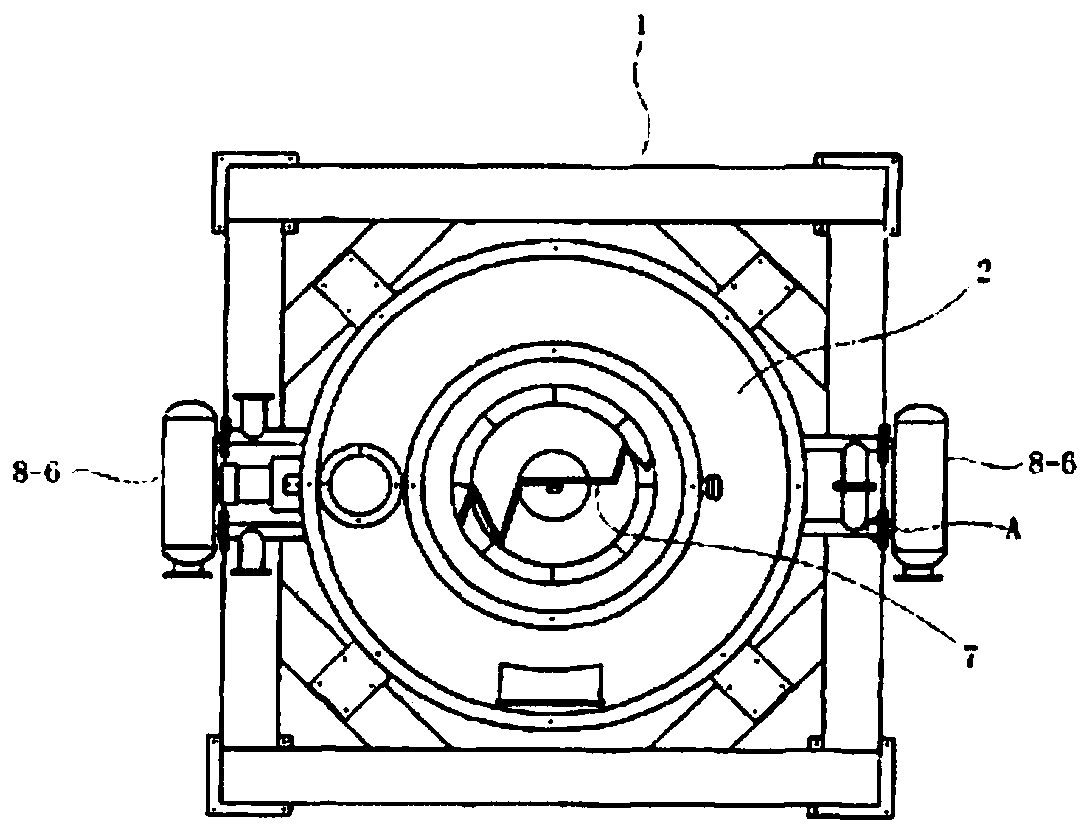

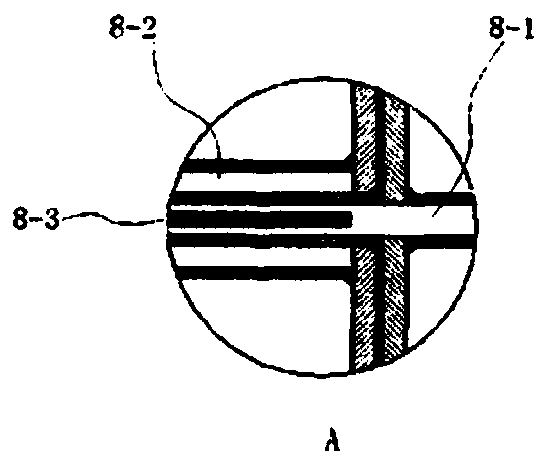

[0035] see Figure 1-4 , an environment-friendly and energy-saving combustion equipment, mainly including a combustion furnace base 1, a combustion furnace body 2, an exhaust outlet 3 and a feeding device 4, wherein the combustion furnace body 2 is a multi-stage structure, including a furnace body lower section 2-1, a furnace body The middle section 2-1 of the furnace body and the upper section 2-3 of the furnace body are connected by flanges between the lower, middle and upper sections of the furnace body. There is a power mechanism 6 for driving the rotating furnace plate 5, and the rotating furnace plate 5 is provided with a water scraper plate 7, and a spiral water protection gas supply ring 8 is provided inside the middle section 2-1 of the furnace body and the upper section 2-3 of the furnace body , the spiral water protection gas su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com