Rotary active explosion venting mechanism

An explosion venting mechanism and rotary technology, which is applied to engine components, mechanical equipment, valve details, etc., can solve problems such as the failure of the blasting device to start in time, the accumulation of equipment pressure, and the lag of the explosion venting process, and achieve good safety and response speed. Fast and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

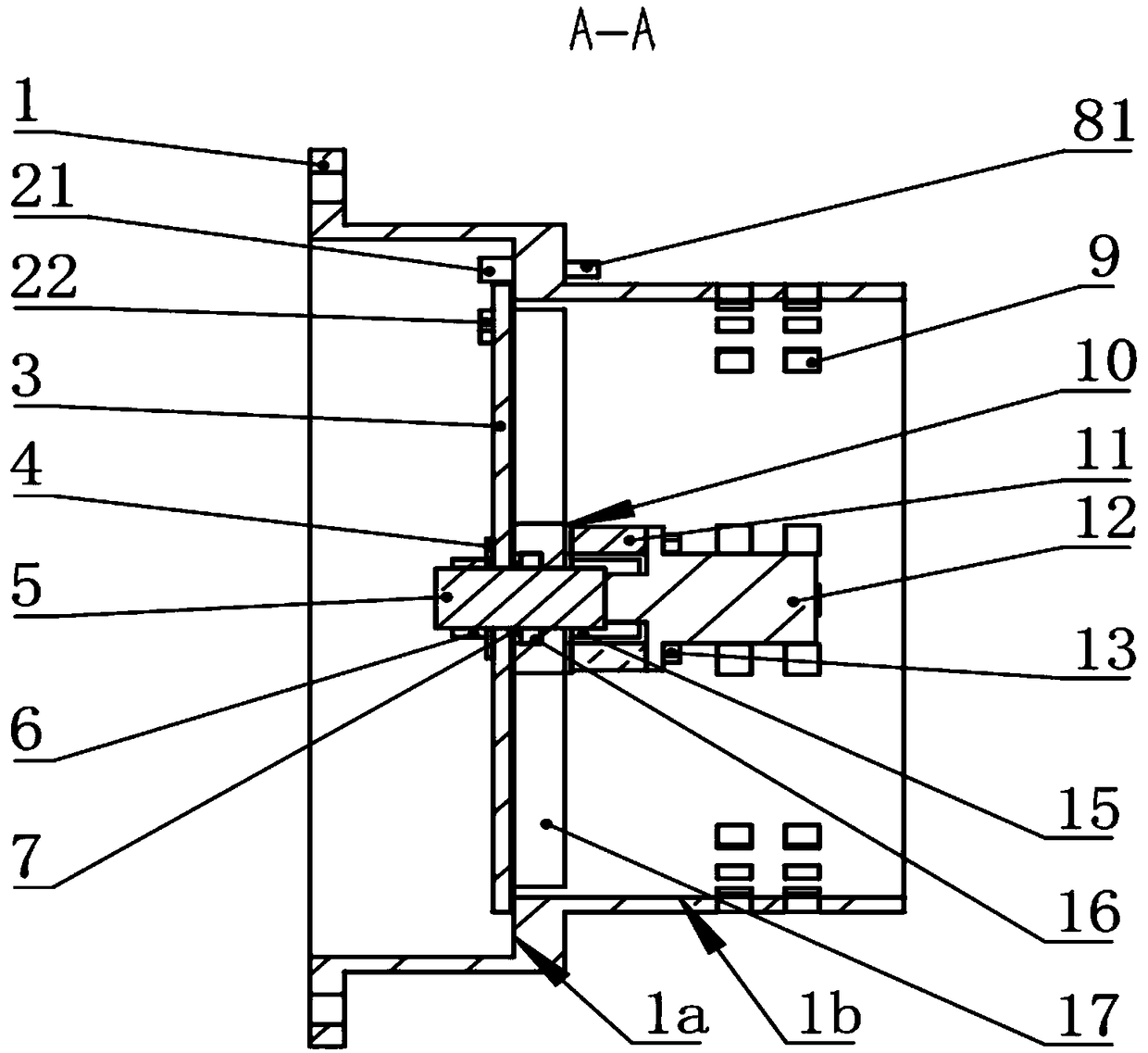

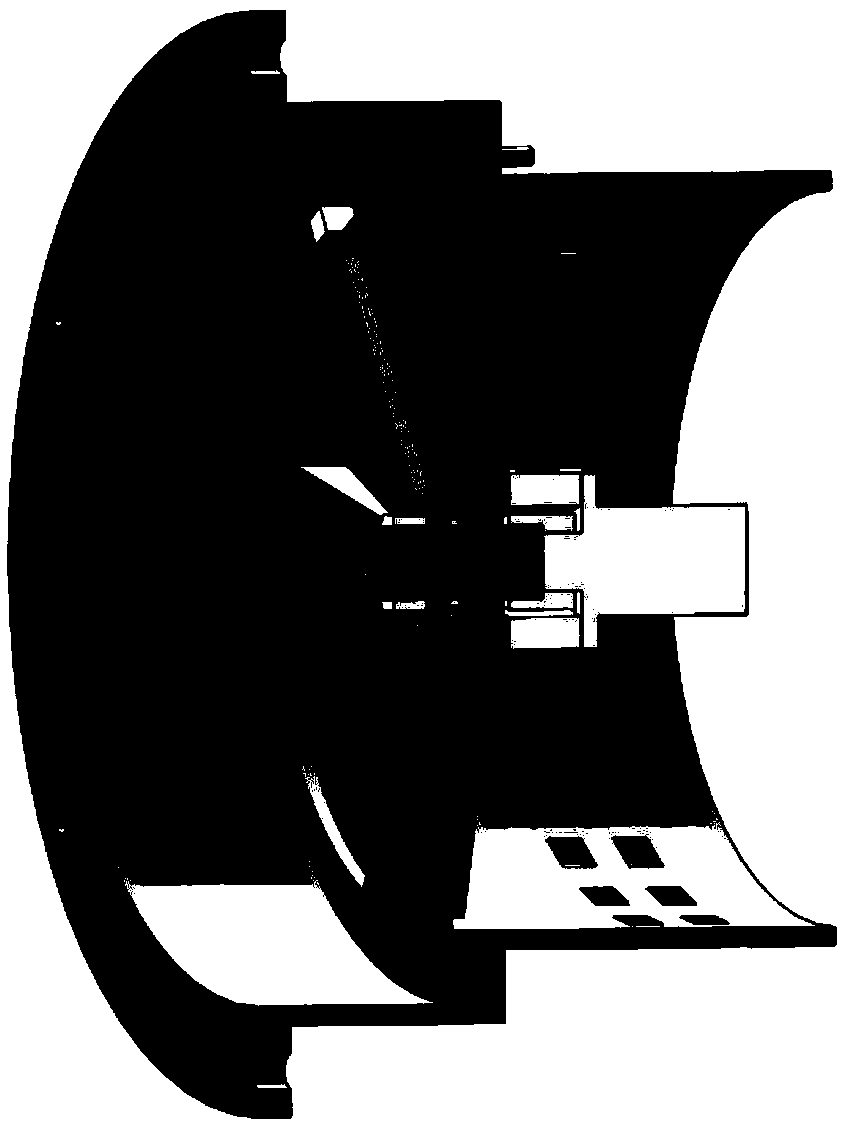

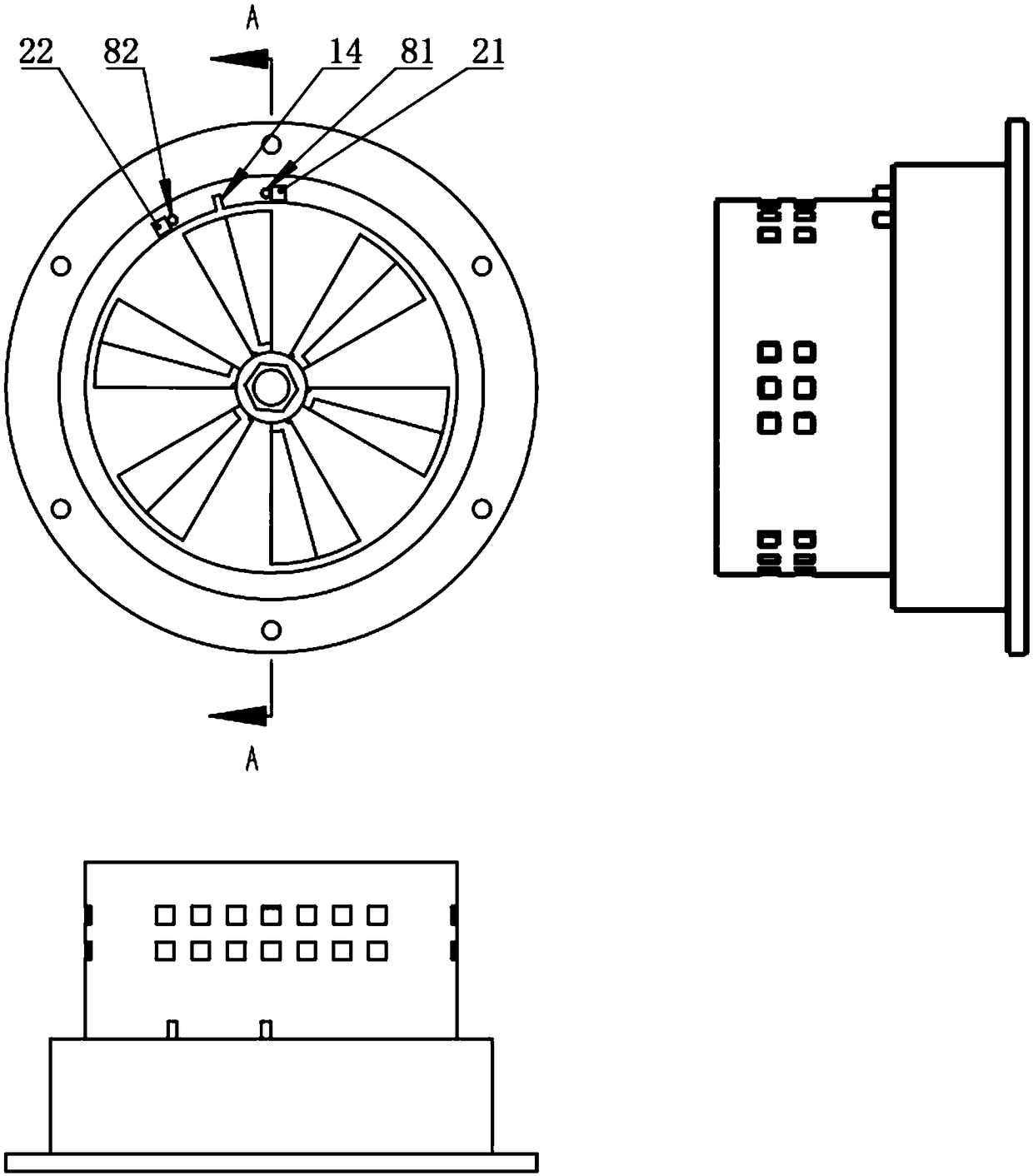

[0034] Such as figure 1 and figure 2 In the rotary active explosion venting mechanism shown, the explosion venting fixed impeller 17 is fixedly connected to the left end of the rear inner wall surface 1b of the explosion venting cylinder 1; the motor base 11 and the angle motor 12 are fixed on the explosion venting fixed impeller 17 by fastening screws 13 Above, a sealing gasket 10 is provided between the explosion venting fixed impeller 17 and the motor seat 11; the angle motor 12 is connected with the rotating shaft 5 through a coupling 15 to drive the rotating shaft 5 to rotate.

[0035] The high temperature resistant bearing 16 set on the rotating shaft 5 is placed in the stepped hole in the center of the explosion venting fixed impeller 17; The rotating impeller 3 is fastened on the rotating shaft 5; the outer edge of the explosion venting rotating im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com