Water purifier booster pump, booster water supply system and booster method

A technology for water purifiers and booster pumps, applied to pumps, pump components, machines/engines, etc., can solve the problems of reduced filtration efficiency, affecting the use of water purifiers, and increased pressure loss, achieving low operating noise and driving The effect of flexible method and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

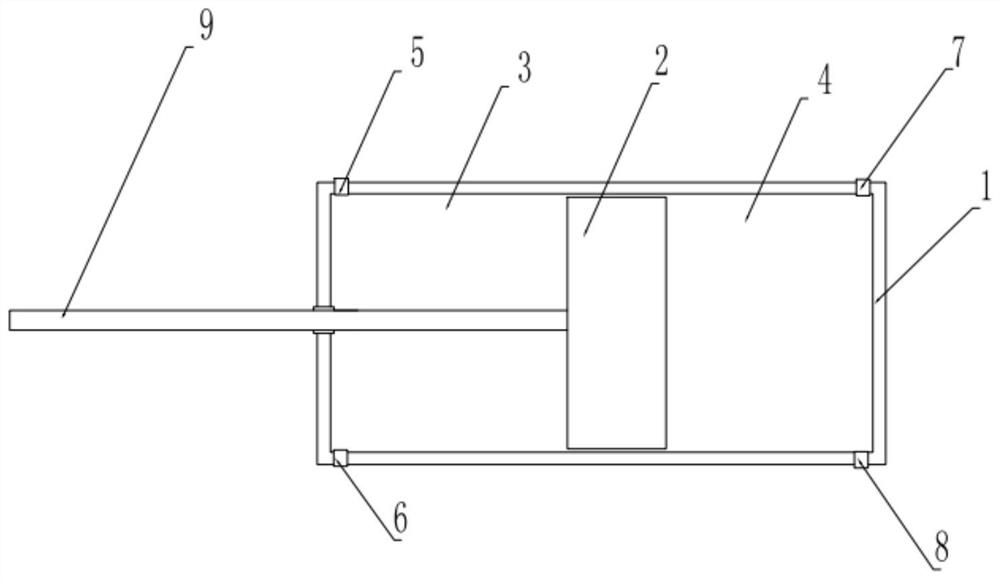

[0031] A water purifier booster pump, comprising a pump body and a drive mechanism, the pump body includes a cylindrical closed cylinder 1, a piston 2 is arranged inside the cylindrical closed cylinder 1, and the piston 2 pushes the cylinder The closed cylinder body is divided into a left pressurized tank 3 and a right pressurized tank 4, a left water inlet 5 and a left water outlet 6 are arranged at the end of the left pressurized tank 3, and the end of the right pressurized tank 4 There is a right water inlet 7 and a right water outlet 8;

[0032] The piston 2 is provided with a piston rod 9, one end of the piston rod 9 is connected to the piston 2, and the other end extends out of the cylindrical closed cylinder 1 and is connected with the drive mechanism 10;

[0033] The driving mechanism 10 can drive the piston 2 to reciprocate left and right.

[0034] The driving mechanism 10 is a linear motor, a two-way cylinder or a crank linkage mechanism.

Embodiment 2

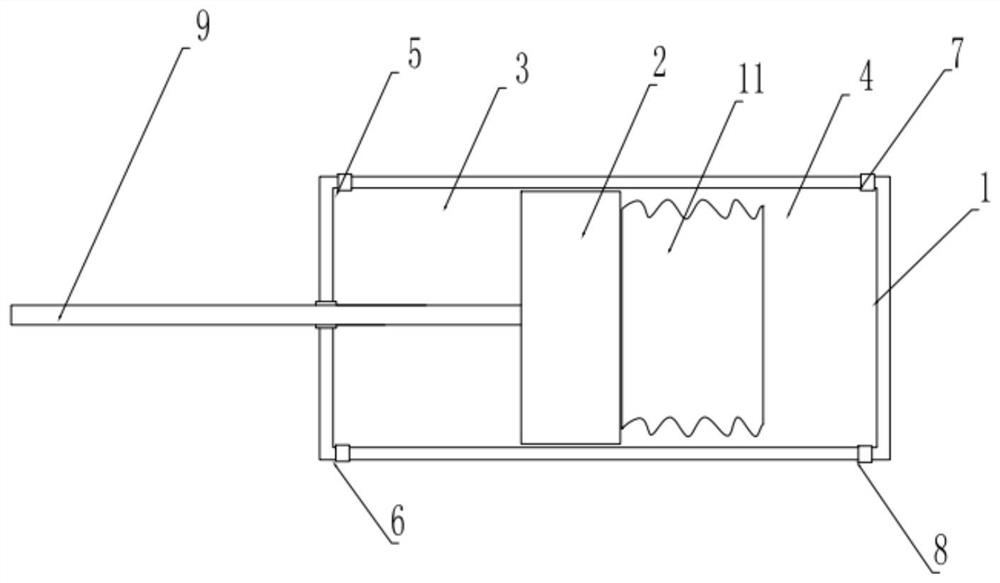

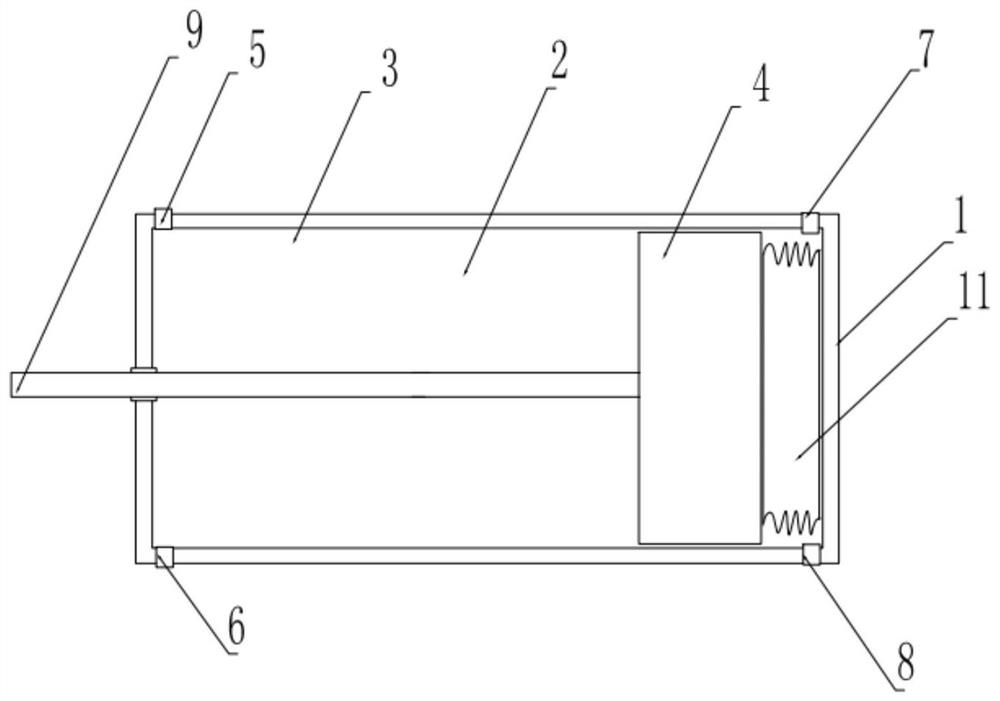

[0036] The difference from Embodiment 1 is that a compressible air bag 11 is also provided in the left pressurized chamber 3 or the right pressurized water chamber 4, and the compressed air bag 11 is fixedly connected with the piston 2. In the middle position, the length of the cavity of the pressurized water chamber provided with the compressed air bag 11 is greater than the length of the cavity of the pressurized water chamber not provided with the compressed air bag. The length difference between the two pressurized water chambers should be smaller than the length of the compressed air bag 11 in the uncompressed state, so as to ensure the alternate high and low pressure water supply.

[0037] The rest are the same as in Embodiment 1 and will not be repeated here.

[0038] The working principle of embodiment 2 is the same as that of embodiment 1. Since the compressible air bag 11 has a certain internal pressure, when the pressurized water chamber is in the state of absorbing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap