Combined cycle engine and hypersonic aircraft

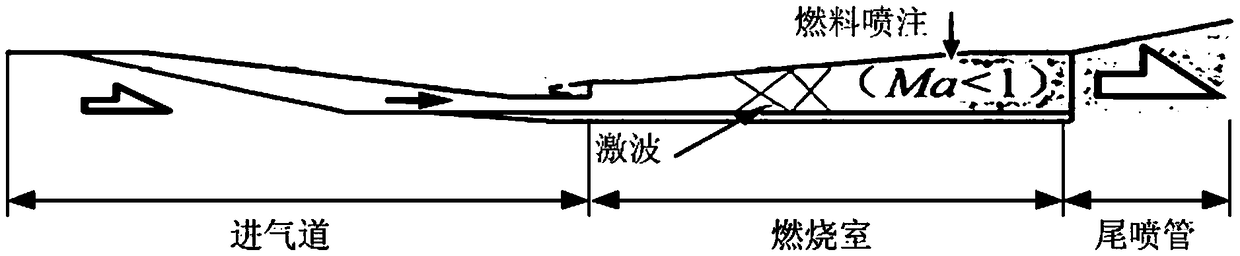

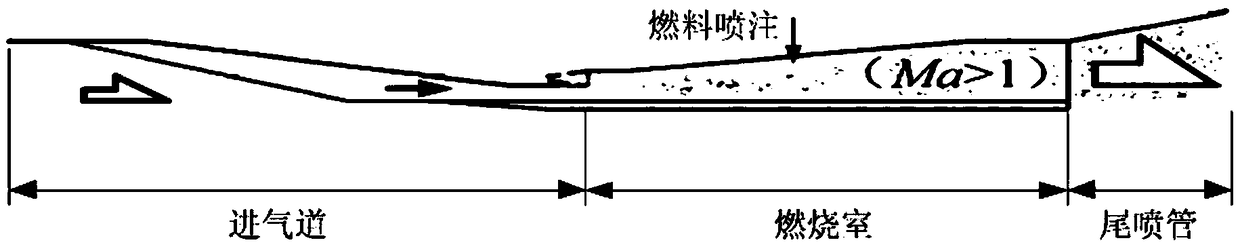

A technology of engine and ramjet, which is applied to the cooling of engine components, machines/engines, and engines. It can solve the problems of difficult mode conversion, long combustion chamber length, and low thermal cycle efficiency, and achieve low conversion difficulty and high thrust. The effect of excellent performance and excellent economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0031] refer to Figure 4 , the preferred embodiment of the present invention provides a combined cycle engine, comprising a rotary detonation ramjet engine 10 and a rocket engine 20 disposed therein. The rotary detonation ramjet engine 10 includes: a casing 11 , the casing 11 is in the shape of a hollow cylinder whose two ends are connected. Also includes a central cone 12, the rear body 121 of the central cone 12 extends into the housing 11 from the intake end of the housing 11 and is connected to the housing 11, and the gap between the housing 11 and the rear body 121 forms the introduction of air into the housing 11 The drainage channel 101 inside, the cavity between the rear end surface of the rear body 121 and the inner wall of the shell 11 fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com