Self-operated water draining gas recovering plunger with variable diameter

A self-supporting technology for drainage and gas recovery, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of slow upward speed of the plunger, liquid leakage, and short recovery time of formation pressure, etc., to reduce leakage The effect of reducing the amount of downlink time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing.

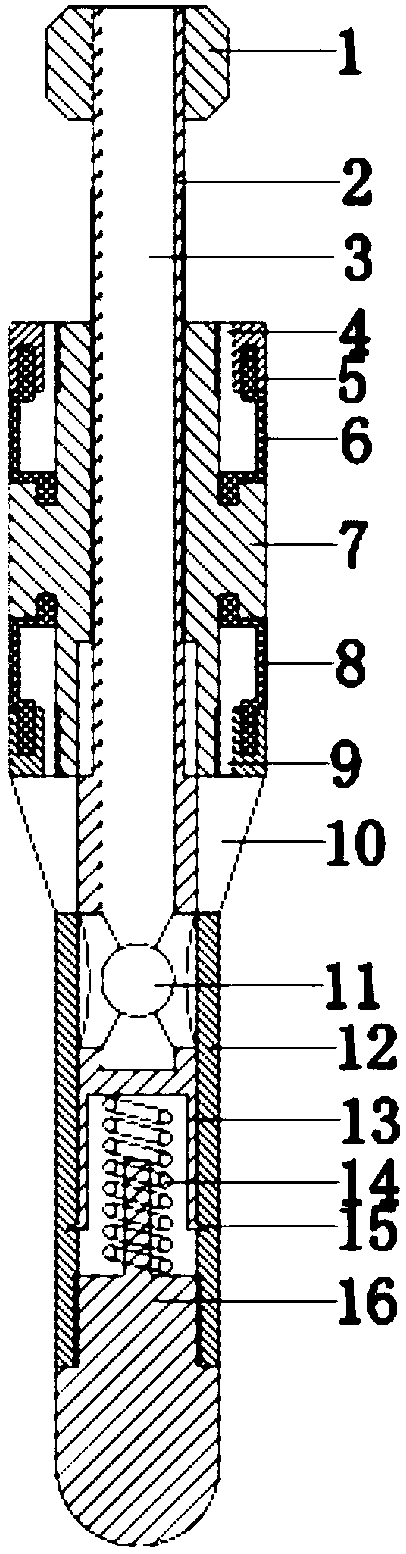

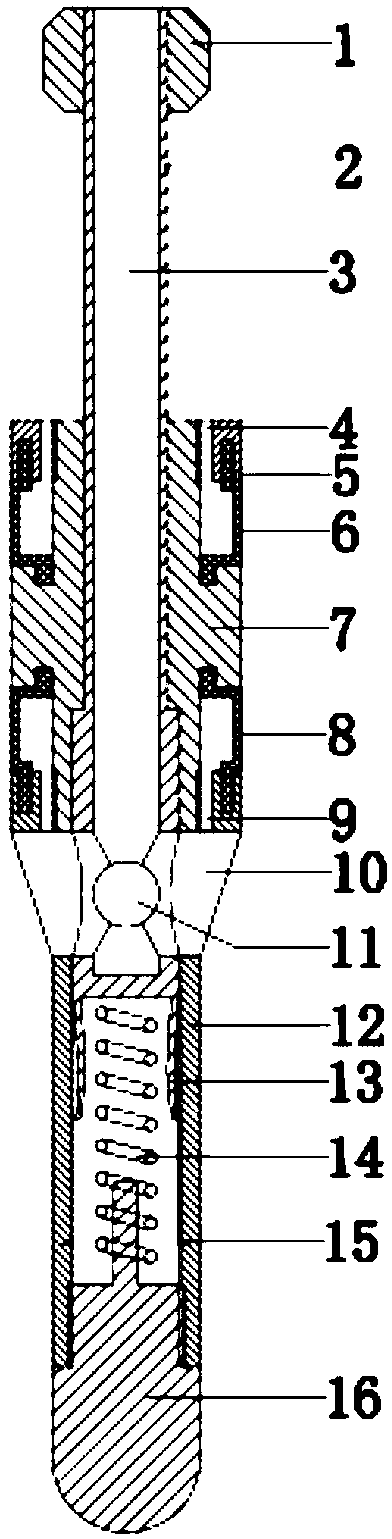

[0015] refer to figure 1 , a variable-diameter self-operated drainage and gas production plunger, including a plunger body 7 of hollow structure, an A sealing rubber cylinder 6 is installed on the upper end of the plunger body 7, and the A sealing rubber cylinder 6 is fixed by an upper end cap 5, and the upper end cap 5 is connected with the plunger body 7 through threads, and there are four liquid inlet holes 4 on the upper end cover 5; the lower end of the plunger body 7 is equipped with a B sealing rubber cylinder 8, and the B sealing rubber cylinder 8 is fixed by the lower half cylinder 12 of the plunger. The lower half cylinder 12 of the plug is connected with the plunger body 7 through threads, and four air inlet holes 9 are arranged at the upper end of the lower half cylinder 12 of the plunger; The sleeve 2 is connected, the upper part of the sliding sleeve 2 is a holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com