A garbage bin with flexible mouth and variable diameter for automatically taking and placing garbage bags

An automatic pick-and-place garbage bag technology, which is applied in the fields of plastic bags, trash cans, and variable-diameter flexible garbage cans, can solve the problems of complex structure of garbage cans, unsmooth operation, and relatively high matching requirements, so as to achieve convenient disassembly and drying , easy to promote, and avoid water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

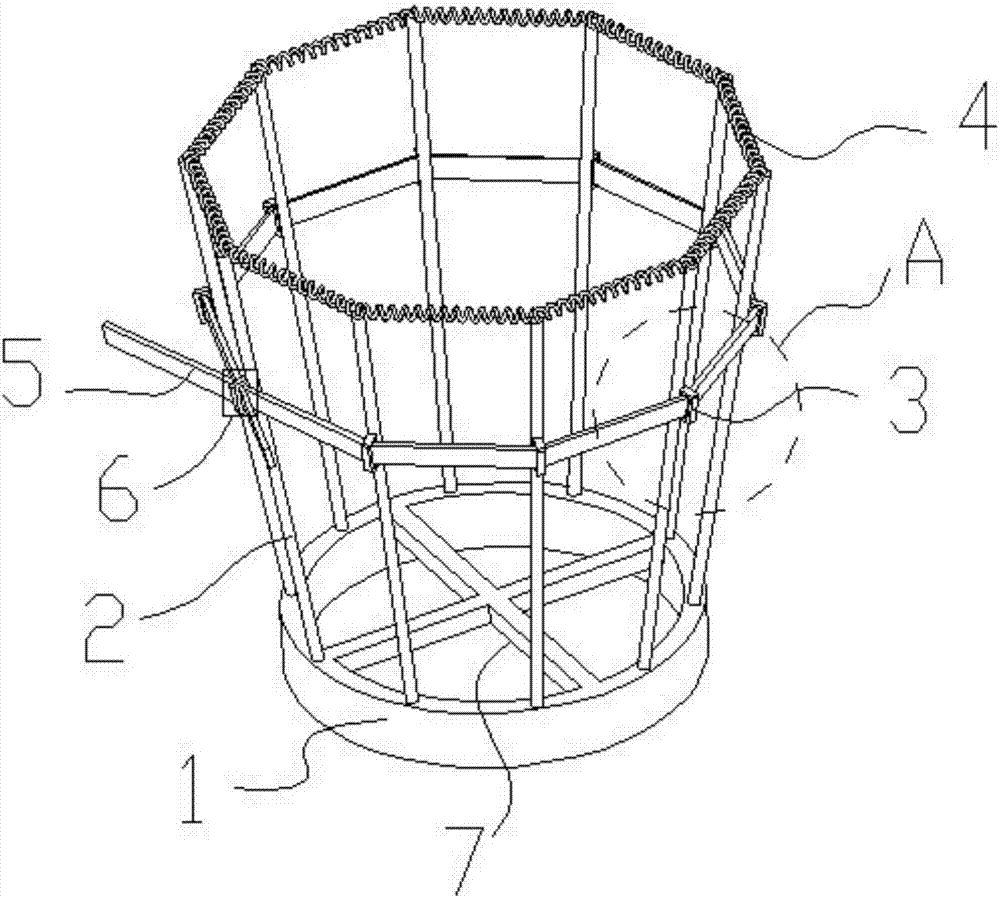

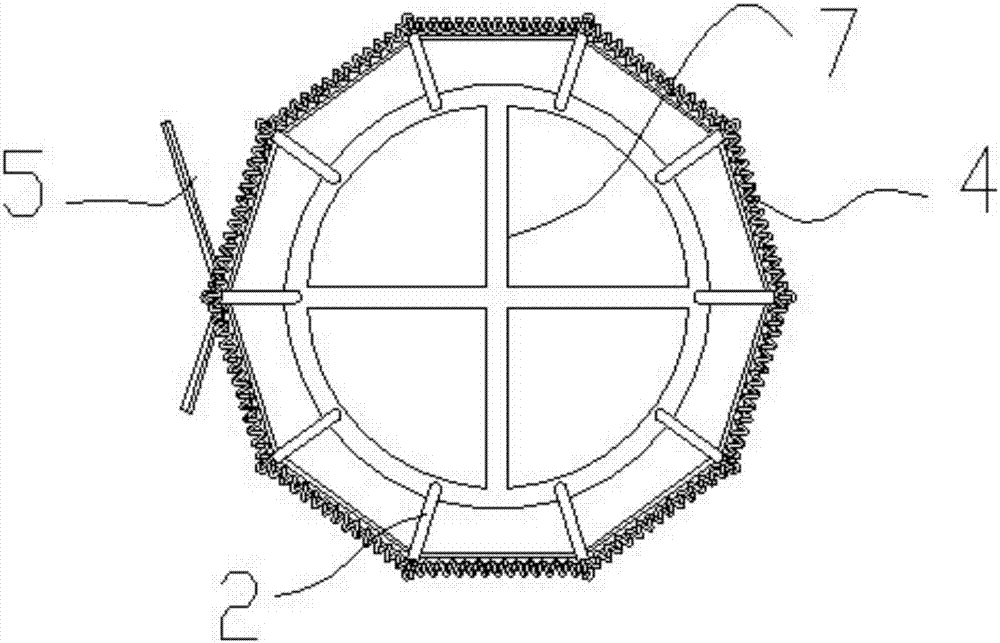

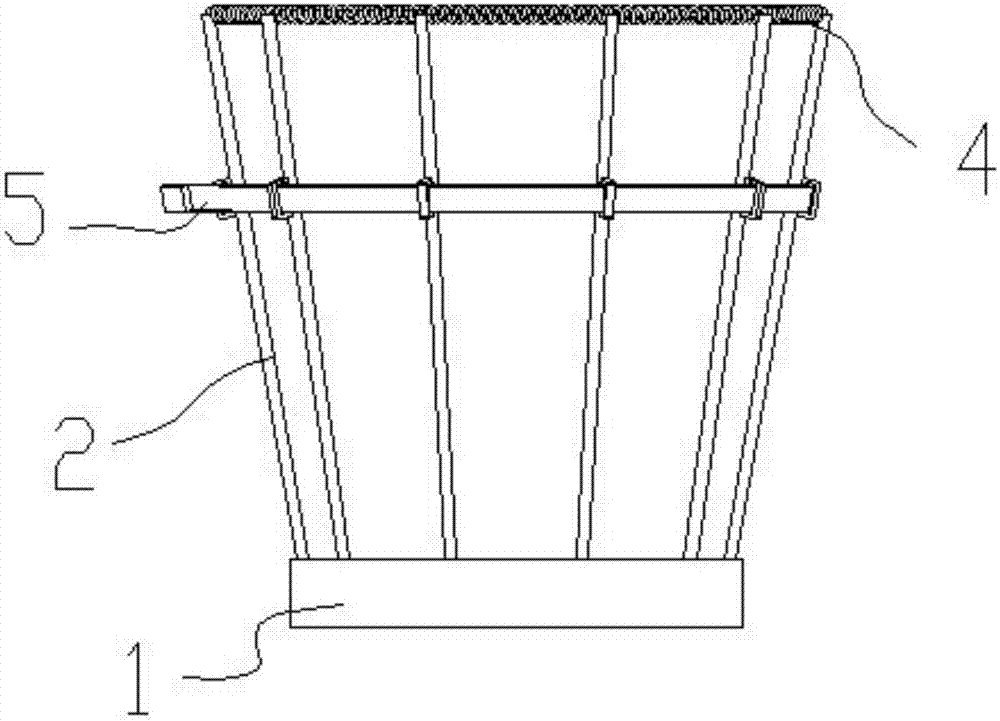

[0043] Such as Figure 1-Figure 4As shown, the specific structure of the present invention is: a kind of garbage bin with flexible mouth and variable diameter for automatically taking and placing garbage bags, which includes a shaped bucket bottom 1 and a number of tube wall uprights 2 evenly arranged around it, and the tube wall uprights 2 are connected with the shaped The barrel bottom 1 is fixedly connected; the two tops of the cylinder wall vertical rods 2 are connected with compression springs 4, and the compression springs 4 form a closed ring structure at the tops of the cylinder wall vertical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com