Stacking type wax planting complete machine

A complete machine, wax ring technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of slow manual welding speed, low product consistency, less wax planting equipment, etc., and achieve high production efficiency. , Good product consistency, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

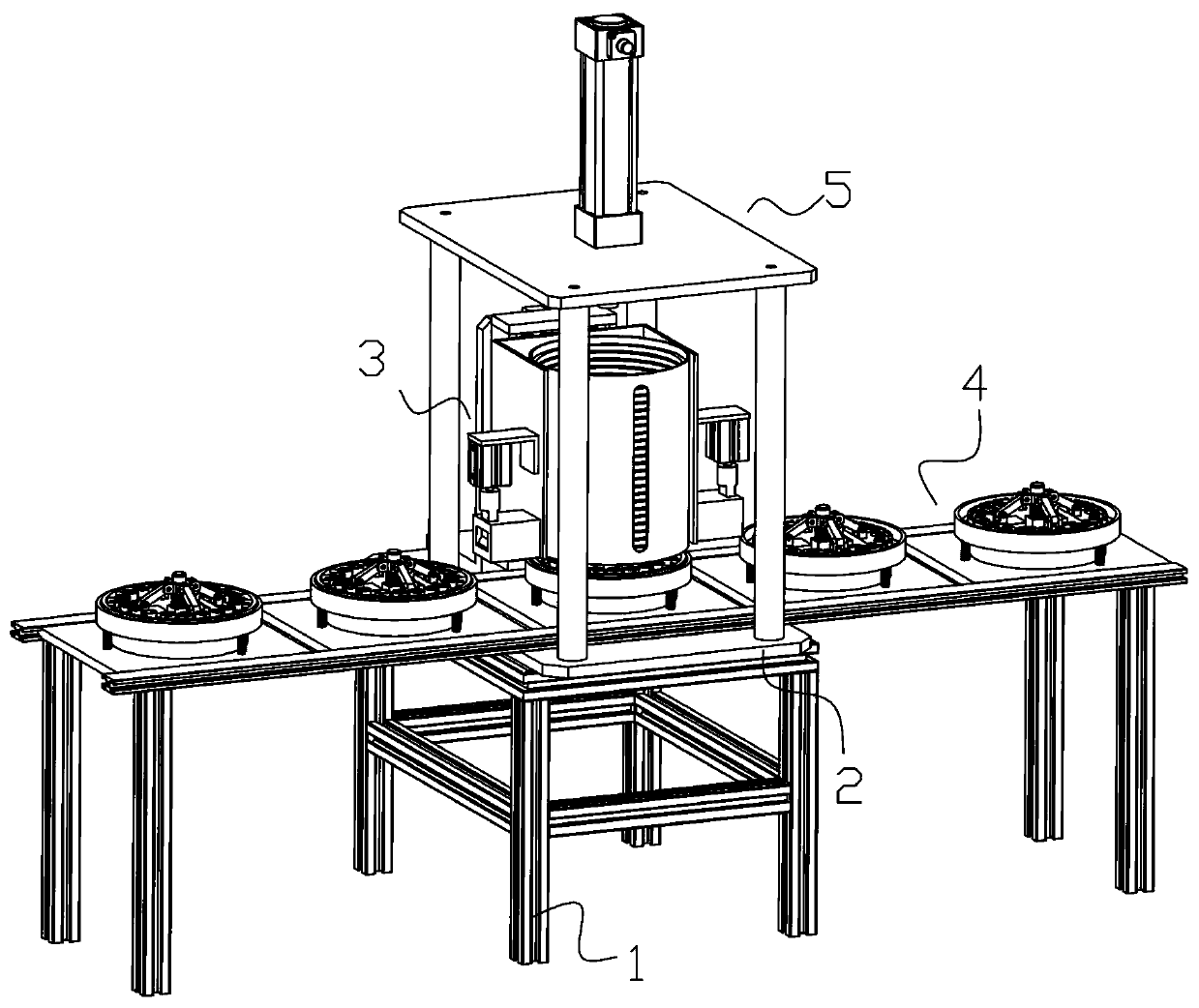

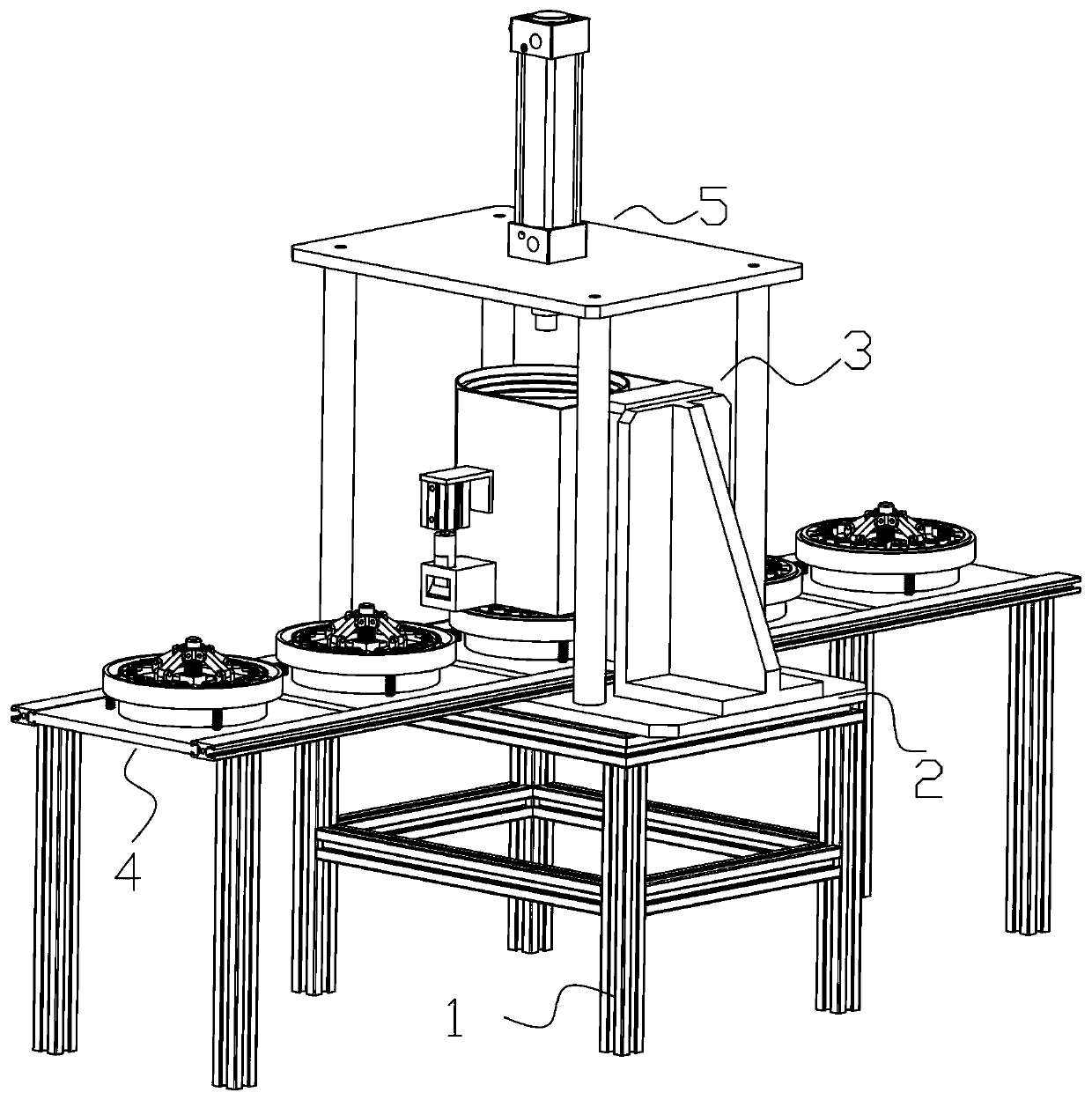

[0036] Such as Figure 1 to Figure 16 As shown, a stacking type wax seeding complete machine described in this embodiment includes a frame 1 and a wax seeding mechanism.

[0037] The wax seeding mechanism includes a bottom plate 2 arranged on the frame 1, and one end of the bottom plate 2 is fixed with a wax ring feeding mechanism 3;

[0038]The wax ring feeding mechanism 3 includes an L-shaped support seat 31, and the long arm of the support seat 31 is fixed with a linear motion device 32; the linear motion device 32 includes a linear motor box 321 and a T-shaped sliding plate 322. The linear motor box 321 is provided with two linear guide rails 323 side by side, and the bottom surface of the cross arm of the sliding plate 322 is fixed with two sliders 324...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com