Anchor cable structure with prefabricated inner anchor head for controlling grouting for many times

An internal anchor head and secondary grouting technology, which can be used in infrastructure engineering, construction, sheet pile walls, etc. Durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

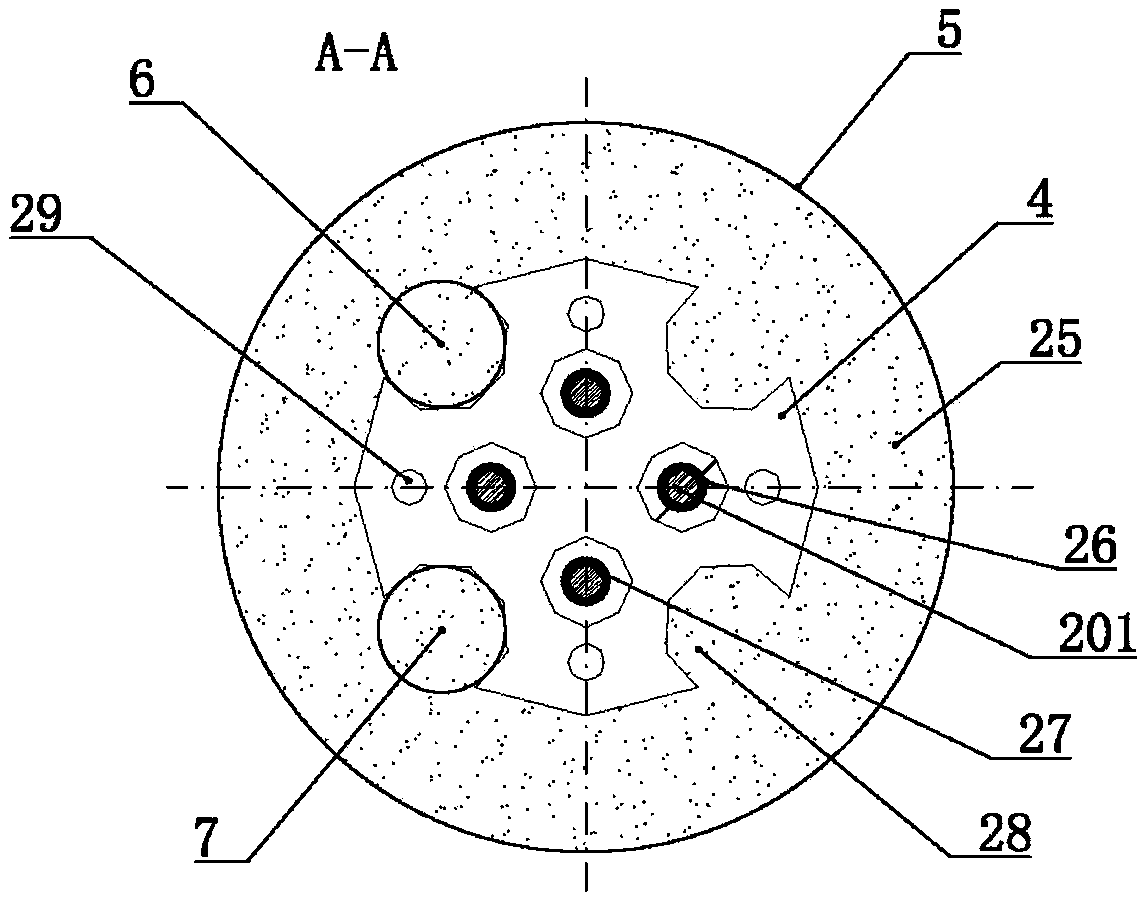

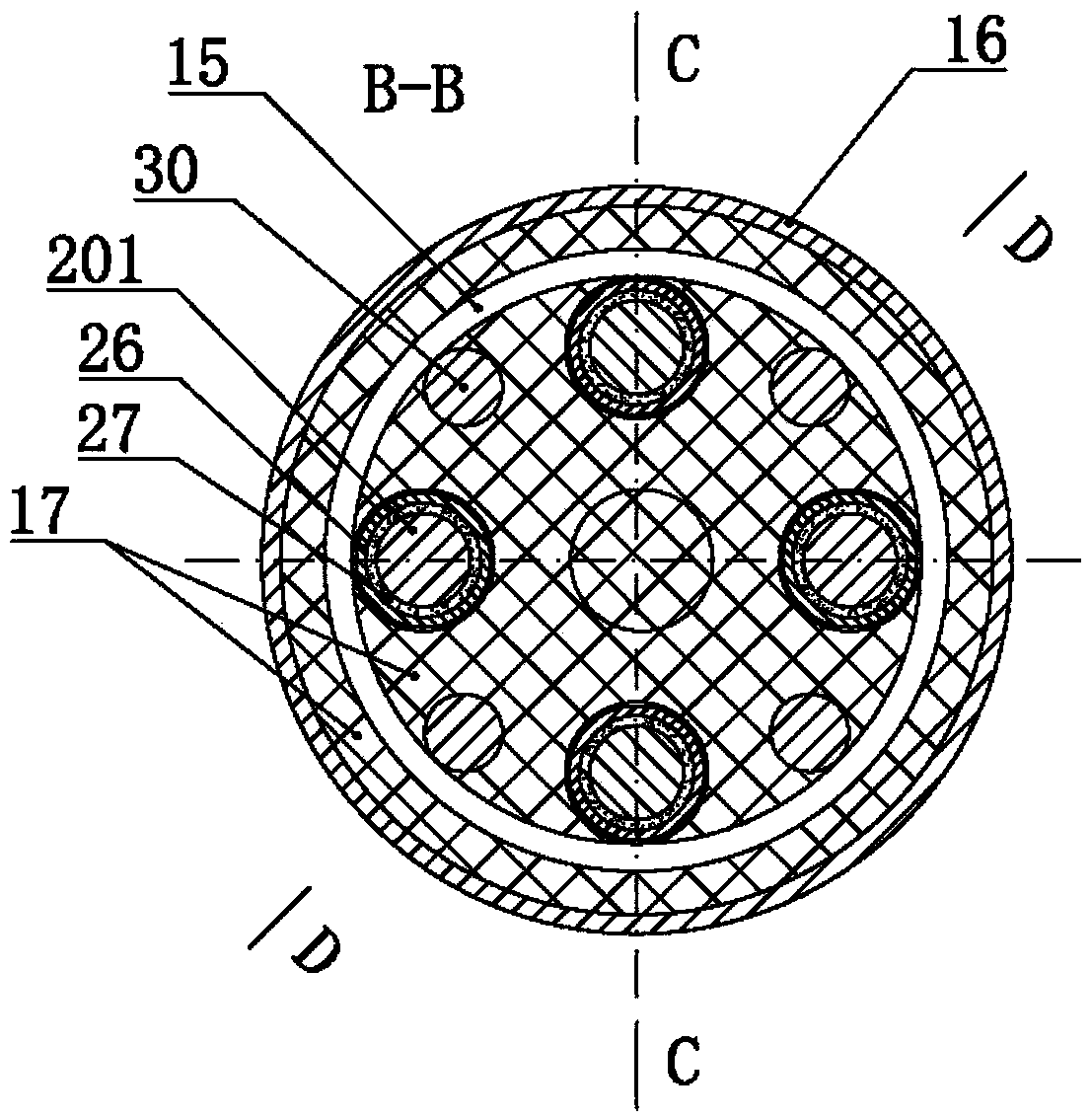

[0033] see Figure 1-8 , a multiple control grouting prefabricated inner anchor head pressure-type anchor cable structure proposed by the present invention, including a prefabricated inner anchor head 1, an unbonded steel strand 2, a tight hoop ring 3, a wire ring 4, and an anchor cable drill Hole 5, primary grouting pipe 6, secondary grouting pipe 7, prefabricated grouting body 17 and outer anchoring end E are described as follows:

[0034] 1. Prefabricated inner anchor head 1:

[0035] Prefabricated inner anchor head 1, consisting of unbonded steel strand 2, stainless steel pipe 14, steel pressure bearing plate 16, prefabricated grouting body (M40 grout) 17, extrusion spring 18, extrusion sleeve 19, grout stopper 20. Grouting eye 21, positioning screw rod 22, nut 23, guide body 24 and threaded rib 30 are formed. in:

[0036] The carrier G is manufactured in a factory. After it is manufactured, it is transported to the construction site. On site, the tail of the stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com