Combined bridge with open pore plate formwork and construction method of combined bridge

A technology of perforated plates and composite beams, applied in bridges, bridge parts, bridge materials, etc., can solve the problem of not getting the maximum utilization of materials, and achieve the goal of improving material utilization, enhancing longitudinal bearing capacity, and accelerating construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

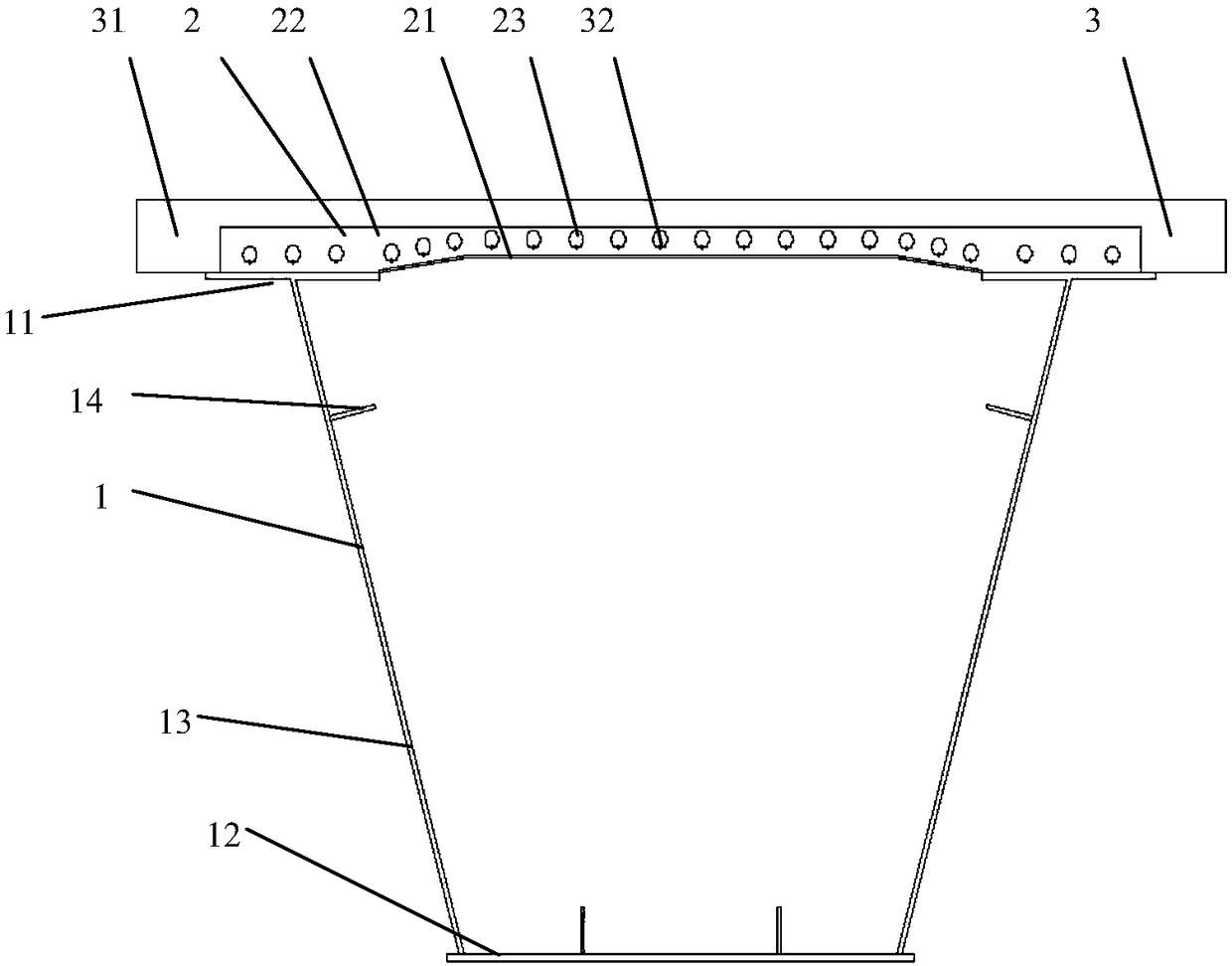

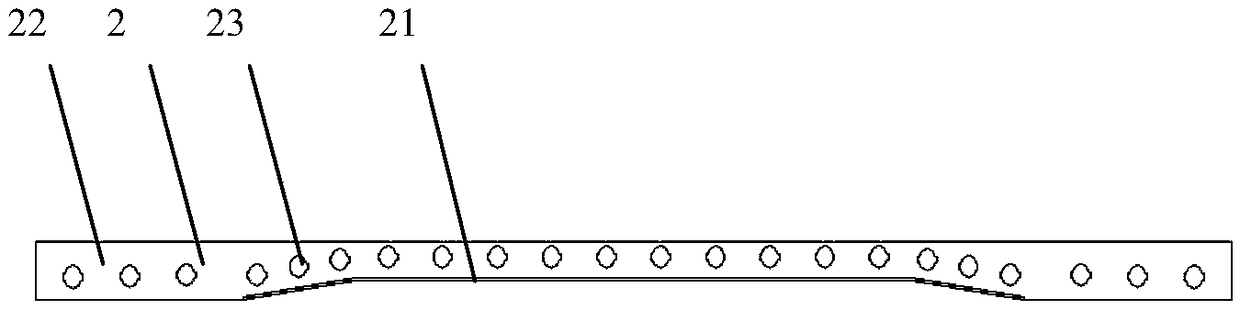

[0037] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 2 As shown, the composite beam 1 includes a horizontal bottom plate 12 and inclined side plates 13 fixedly connected to both ends of the bottom plate 12 , the upper ends of the two side plates 13 are respectively provided with upper flanges 11 . The side plate 13, the bottom plate 12 and the other side plate 13 form a "U" shape, and the upper ends of the two side plates 13 are inclined outward.

[0038] In a further embodiment of the present invention, the composite beam 1 further includes several reinforcing ribs 14, and the several reinforcing ribs 14 are fixedly connected with the bottom plate 12 and the side plate 13 respectively.

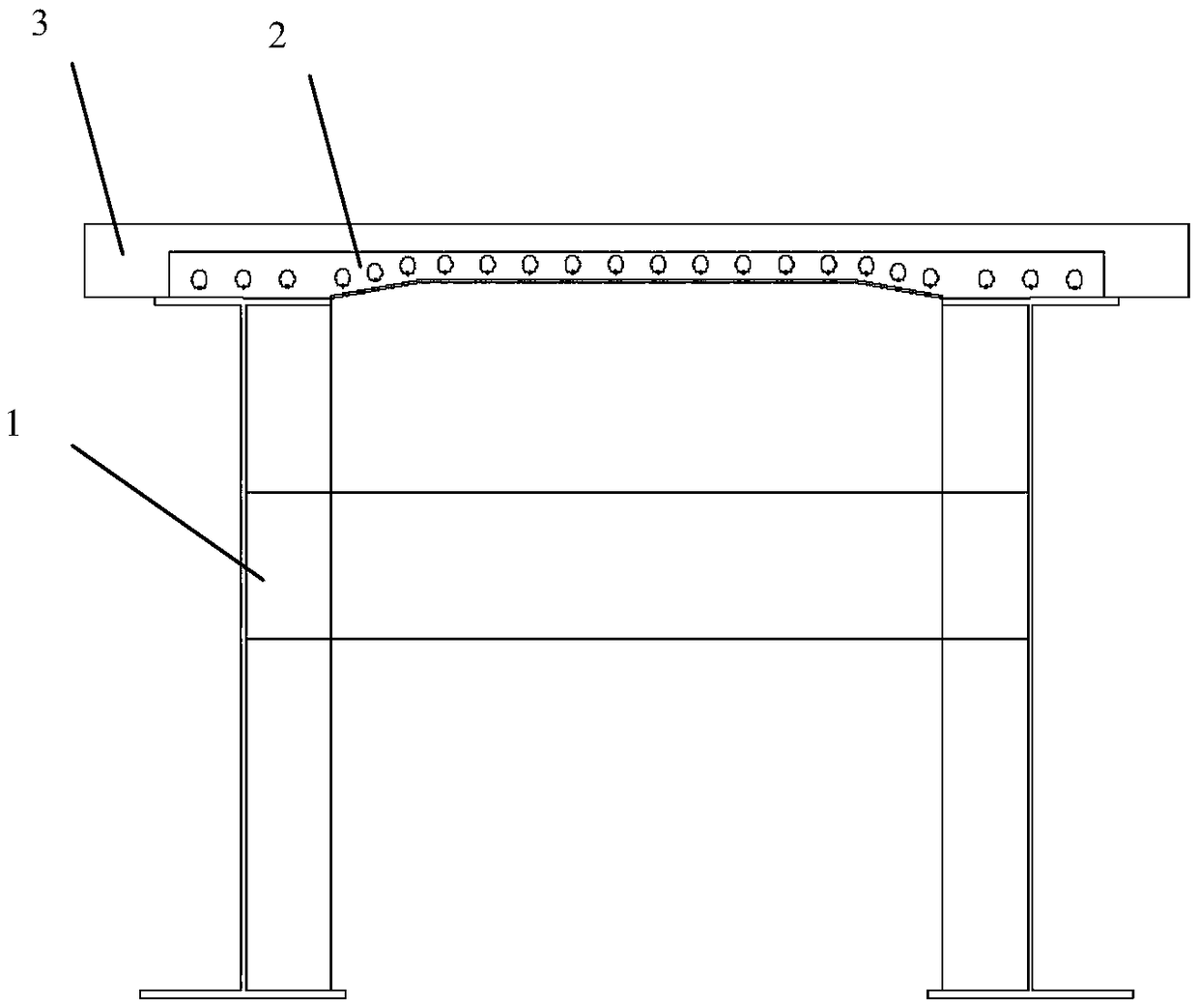

[0039] In further embodiments of the present invention, please continue to refer to image 3 , Figure 4 As shown, the composite beam 1 is a composite steel box girder, a composite steel plate girder or a composite steel truss girder.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com