Preparation method of elastic non-woven fabric and elastic non-woven fabric

A non-woven fabric and elastic technology, applied in the field of elastic non-woven fabrics, can solve the problems of weak elasticity and inability to adjust the elasticity in both horizontal and vertical directions, and achieve the effects of strong elasticity, improved elasticity, and enhanced adjustment functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

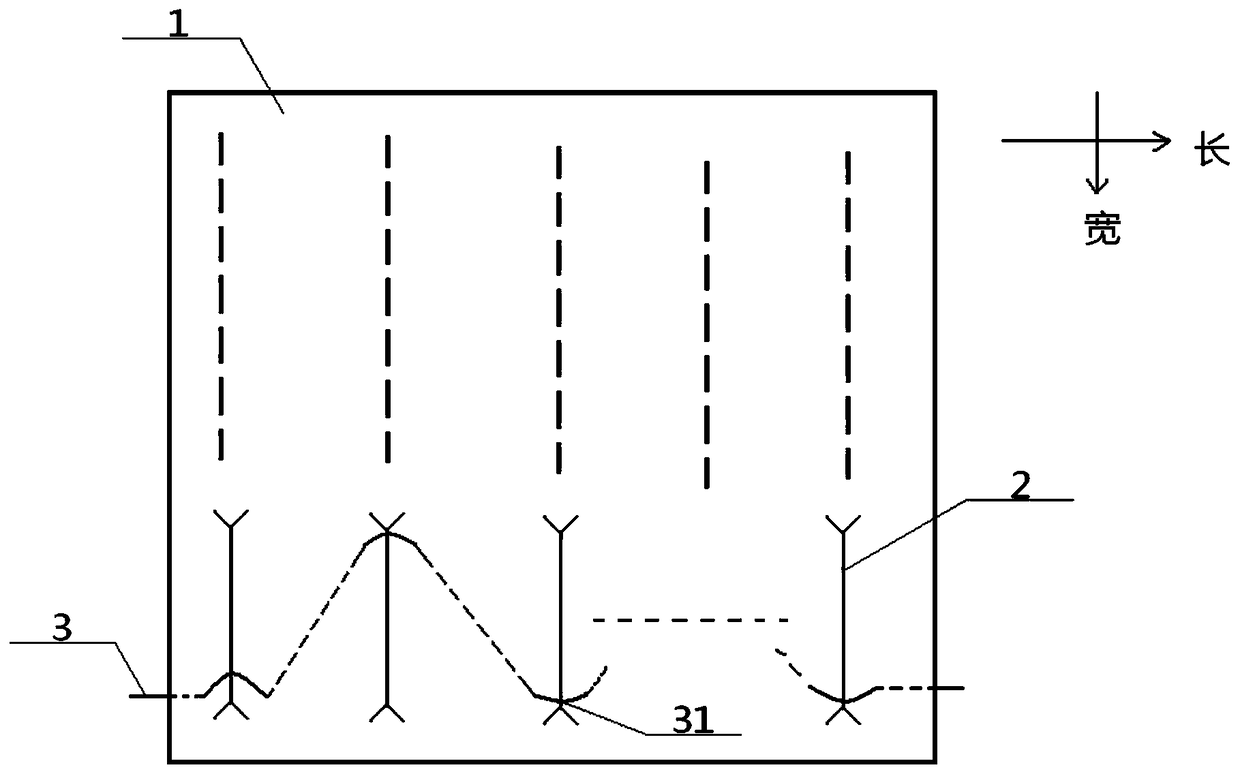

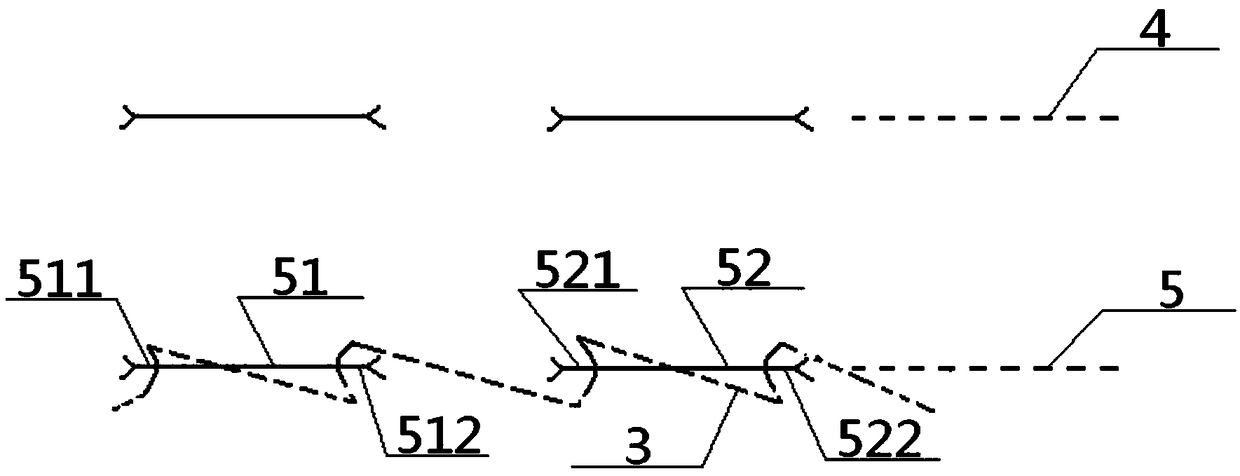

[0040] see figure 1 - Figure 9 , a kind of preparation method of elastic nonwoven fabric, described preparation method comprises following process:

[0041] Fiber web stitching process: First, a plurality of elastic ribs 2 are arranged in parallel and equally spaced on the reverse side of the fiber web 1. The front side of 1 introduces a plurality of composite filaments 3 in parallel, the introduction direction of the composite filaments 3 is along the length direction of the fiber web 1, and the stitching method after the introduction of the composite filaments 3 is repeated penetration and exit of the fiber web 1 to consolidate the two ends of each elastic tendon 2 on the opposite surface of the fiber net 1 to obtain a consolidated net body; There is a consolidation point 31 at both ends of the tendon 2; during the overall process of each composite filament 3 penetrating and passing through the fiber web 1, the composite filament 3 swings back and forth along the length d...

Embodiment 1

[0063] see figure 1 - Figure 9 , a method for preparing an elastic nonwoven fabric, comprising the following processes:

[0064] Fiber web stitching process: First, a plurality of elastic ribs 2 are arranged in parallel and equally spaced on the reverse side of the fiber web 1. The front side of 1 introduces a plurality of composite filaments 3 in parallel, the introduction direction of the composite filaments 3 is along the length direction of the fiber web 1, and the stitching method after the introduction of the composite filaments 3 is repeated penetration and exit of the fiber web 1 to consolidate the two ends of each elastic tendon 2 on the opposite surface of the fiber net 1 to obtain a consolidated net body; There is a consolidation point 31 at both ends of the tendon 2; during the overall process of each composite filament 3 penetrating and passing through the fiber web 1, the composite filament 3 swings back and forth along the length direction of the fiber web 1 ...

Embodiment 2

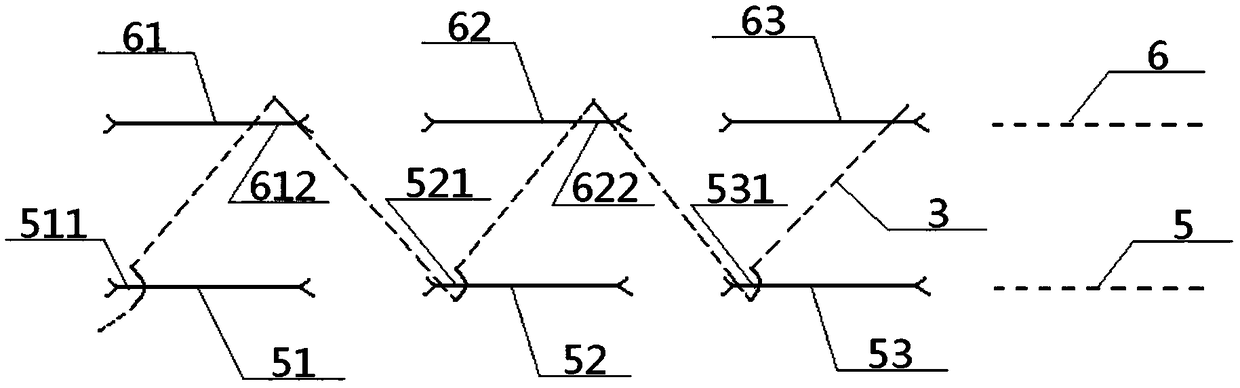

[0068] Basic content is the same as embodiment 1, the difference is:

[0069] see Figure 8 , on the opposite side of the fiber web 1, along the length or width direction of the fiber web 1, a plurality of additional elastic threads 12 are arranged in parallel and at equal intervals. The opposite side of the fiber web 1, and perpendicular to the direction of the elastic tendon 2, repeatedly penetrates and passes through the fiber web 1 at the composite filament 3 so that both ends of each elastic tendon 2 are consolidated on the fiber web 1 On the reverse side, another composite filament 3 is repeatedly inserted into and out of the fiber web 1 so that each additional elastic filament 12 is consolidated on the reverse side of the fiber web 1, and each composite filament 3 and its corresponding additional The elastic wires 12 need to be handed over multiple times, and each handover point is called an additional contact point 13 , and there are multiple additional contact points...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com