High density total oxygen short process high-efficiency cleaning iron-making process

A short-flow, high-density technology, applied in furnace types, furnaces, and gas emission reduction, etc., can solve the problems of insufficient chemical energy and physical heat utilization of coal gas, difficult pre-reduction control, high coal consumption and oxygen consumption, and save energy. The cost of grinding and beneficiation, the reduction of energy consumption and pollutant discharge, the effect of reducing comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

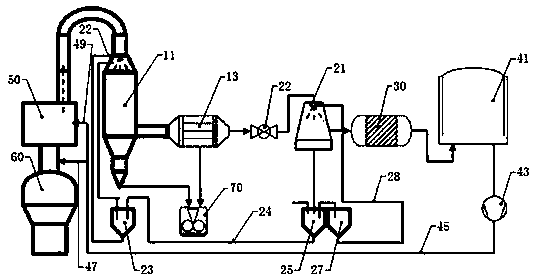

[0028] The present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments are only to further illustrate the present invention, rather than limit the present invention.

[0029] For further specifying the technical scheme of the present invention, discuss with regard to the concrete steps of the present invention below:

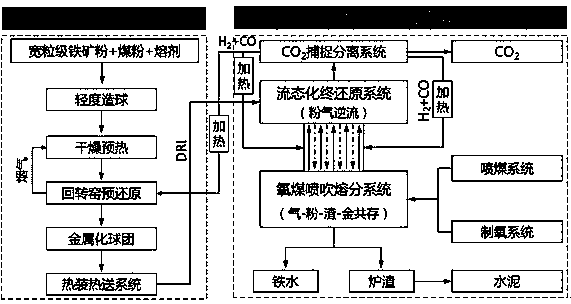

[0030] see figure 1 , a high-density full-oxygen short-process efficient and clean ironmaking process, including the following steps:

[0031] S1: Raw material preparation: The present invention uses iron ore powder with wide grain size as raw material, which saves the cost of grinding and beneficiation, uses anthracite as reducing agent, saves the coking process of blast furnace ironmaking process, and uses slaked lime, dolomite, etc. as a flux. The wide-sized iron ore powder and coal powder are granulated in a disc pelletizer to obtain wide-sized carbon-containing pell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com