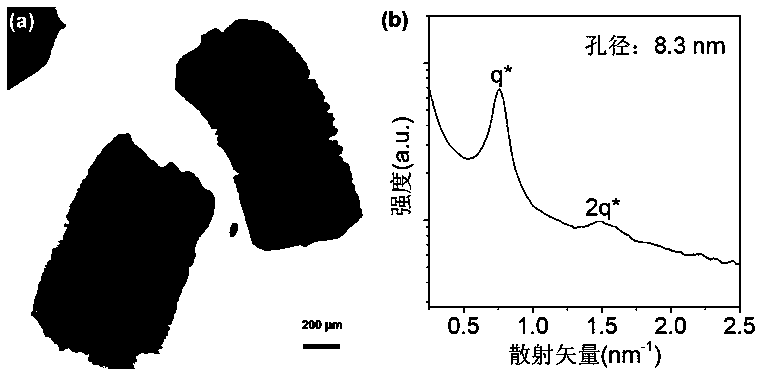

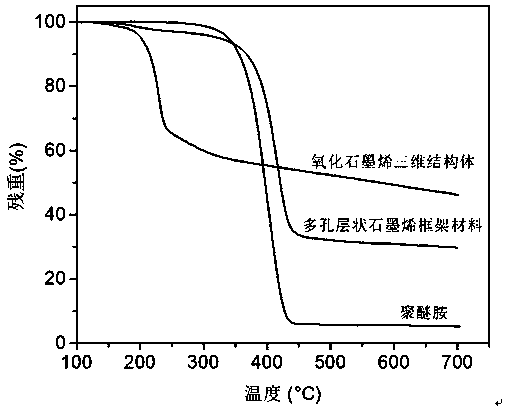

Porous layered graphene frame material as well as preparation method and application thereof

A framework material and graphene technology, applied in the field of materials, can solve the problems of wide pore size distribution, poor pore arrangement regularity, and large pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 100 mg of diaminopolyetheramine with a molecular weight of 2000 g / mol to 50 ml of an aqueous suspension of graphene oxide three-dimensional structure with a concentration of 1 mg / ml, mix well and react under heating conditions at 50°C 10 hours gave a mixture.

[0029] (2) The mixture obtained in step (1) is centrifuged and washed several times to remove unreacted polyetheramine, and obtain a wet state porous layered graphene framework material.

[0030] (3) Freeze-drying the wet state porous layered graphene framework material obtained in step (2) to obtain a dry state porous layered graphene framework material.

Embodiment 2

[0032] (1) Add 100 mg of bisaminopolyetheramine with a molecular weight of 600 g / mol to 50 ml of an aqueous suspension of graphene oxide three-dimensional structure with a concentration of 1 mg / ml, mix well and react under heating conditions at 70°C 10 hours gave a mixture.

[0033] (2) The mixture obtained in step (1) is subjected to vacuum filtration-water washing several times to remove unreacted polyetheramine, and obtain a wet-state porous layered graphene framework material.

[0034] (3) Naturally drying the wet state porous layered graphene framework material obtained in step (2) to obtain a dry state porous layered graphene framework material.

Embodiment 3

[0036] (1) Add 100 mg of bisaminopolyetheramine with a molecular weight of 2000 g / mol to 50 ml of an aqueous suspension of graphene oxide three-dimensional structure with a concentration of 1 mg / ml, mix well and react under heating conditions at 100°C 2 hours to give a mixture.

[0037] (2) The mixture obtained in step (1) is centrifuged and washed with ethanol several times to remove unreacted polyetheramine, and obtain a wet state porous layered graphene framework material.

[0038] (3) Freeze-drying the wet state porous layered graphene framework material obtained in step (2) to obtain a dry state porous layered graphene framework material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com