A kind of porous layered graphene frame material and its preparation method and application

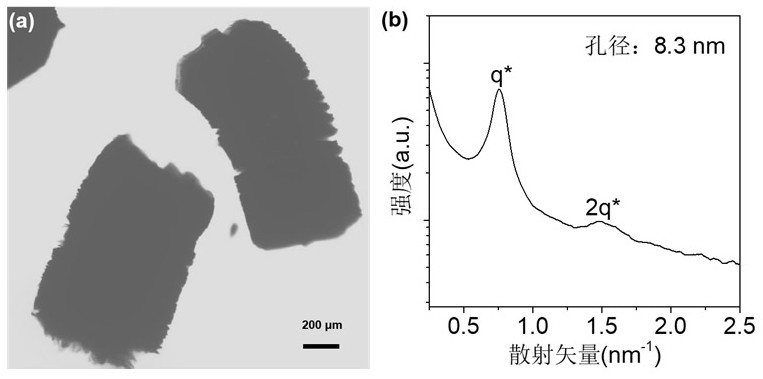

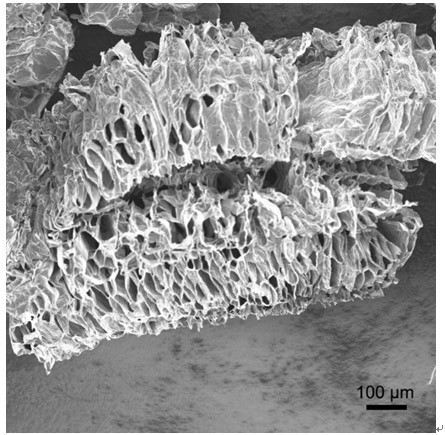

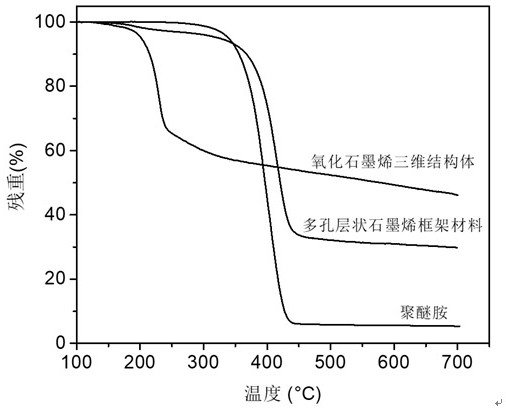

A frame material, graphene technology, applied in the field of materials, can solve the problems of poor channel arrangement, large pore size, wide pore size distribution, etc., to increase the pore size, accurately controllable adjustment, and ensure the order and uniformity of the channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 100 mg of diaminopolyetheramine with a molecular weight of 2000 g / mol to 50 ml of an aqueous suspension of graphene oxide three-dimensional structure with a concentration of 1 mg / ml, mix well and react under heating conditions at 50°C 10 hours gave a mixture.

[0029] (2) The mixture obtained in step (1) is centrifuged and washed several times to remove unreacted polyetheramine, and obtain a wet state porous layered graphene framework material.

[0030] (3) Freeze-drying the wet state porous layered graphene framework material obtained in step (2) to obtain a dry state porous layered graphene framework material.

Embodiment 2

[0032] (1) Add 100 mg of bisaminopolyetheramine with a molecular weight of 600 g / mol to 50 ml of an aqueous suspension of graphene oxide three-dimensional structure with a concentration of 1 mg / ml, mix well and react under heating conditions at 70°C 10 hours gave a mixture.

[0033] (2) The mixture obtained in step (1) is subjected to vacuum filtration-water washing several times to remove unreacted polyetheramine, and obtain a wet-state porous layered graphene framework material.

[0034] (3) Naturally drying the wet state porous layered graphene framework material obtained in step (2) to obtain a dry state porous layered graphene framework material.

Embodiment 3

[0036] (1) Add 100 mg of bisaminopolyetheramine with a molecular weight of 2000 g / mol to 50 ml of an aqueous suspension of graphene oxide three-dimensional structure with a concentration of 1 mg / ml, mix well and react under heating conditions at 100°C 2 hours to give a mixture.

[0037] (2) The mixture obtained in step (1) is centrifuged and washed with ethanol several times to remove unreacted polyetheramine, and obtain a wet state porous layered graphene framework material.

[0038] (3) Freeze-drying the wet state porous layered graphene framework material obtained in step (2) to obtain a dry state porous layered graphene framework material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com