End effector of metal surface dirt removing robot

An end-operator, metal surface technology, applied in manipulators, manufacturing tools, etc., can solve the problems of cleaning the end-operator without surface position compensation, dust and other impurities without cleaning operations, etc., to achieve good surface cleaning effect, convenient for daily maintenance, Install simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

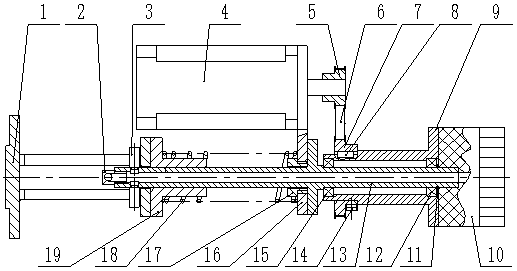

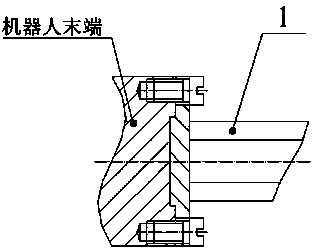

[0013] combined with Figure 1-2 The structure and operation of the present invention will be explained.

[0014] The end manipulator of the metal surface dirt cleaning robot of the present invention includes: a connecting seat 1, a quick joint elbow 2, a guide column 3, a motor 4, a small pulley 5, a timing belt 6, a large pulley 7, a flat key 8, and a pulley shaft 9 , Disc brush 10, circlip 11, right end bearing 12, inner tube 13, set screw 14, left end bearing 15, motor frame 16, flange 17, spring 18 and linear bearing 19.

[0015] The connecting seat 1 generally has a flange on the left end and a right end, and a shaft section in the middle. The left side of the connection seat 1 is matched and fixedly connected with the end of the general industrial robot through the flange plate at the left end. In the middle of the two flanges of the connecting seat 1, two guide grooves perpendicular to each other are provided in the axial direction. A linear bearing 19 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com