Tool magazine pneumatic tool-clamping device for numerically-controlled machine tool

A technology of CNC machine tools and pneumatic clamps, which is applied in the field of CNC machine tools, can solve problems such as personnel injury, poor tool support in the tool magazine, and affect the normal use of machine tools, and achieve high production efficiency and easy manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

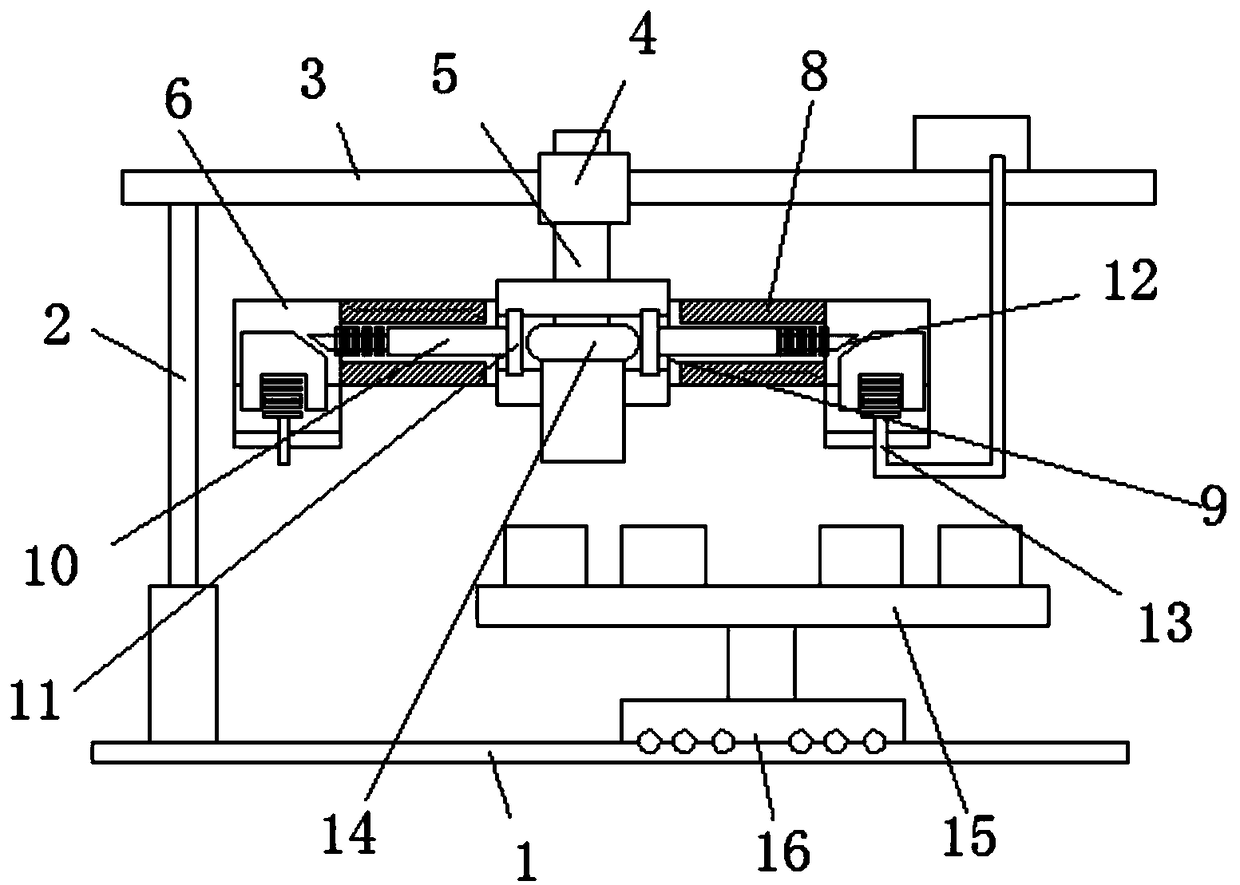

[0011] Referring to the accompanying drawings, a pneumatic knife clamping device for a tool magazine for a CNC machine tool includes a base 1, a support column 2 is provided on the base 1, a beam plate 3 is provided on the top of the support column 2, and a beam plate 3 is provided on the base A moving seat 4 is slidingly installed, the lower end of the moving seat 4 is connected with a rotating shaft 5, the lower end of the rotating shaft 5 is connected with a supporting arm 6, the middle end of the supporting arm 6 is connected with the rotating shaft, and the left and right sides of the supporting arm 6 Sleeves 8 are respectively arranged at the ends, and a cavity 9 is arranged in the sleeve 8, and an extruding rod 10 is slidably installed in the cavity 9, and an extruding piece 11 is arranged at the end of the extruding rod 10, The end of the extrusion rod 10 is provided with a wedge-shaped surface 12 , and a push rod 13 is arranged below the wedge-shaped surface 12 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com