Rolling outlet real-time monitoring rolling quality device

A real-time monitoring and discharge port technology, applied in metal rolling, length measuring device, metal rolling and other directions, can solve the problems of unqualified phosphor bronze ball billets and different models, and improve production efficiency and The effect of product inspection rate, reduction of processing waste, and improvement of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

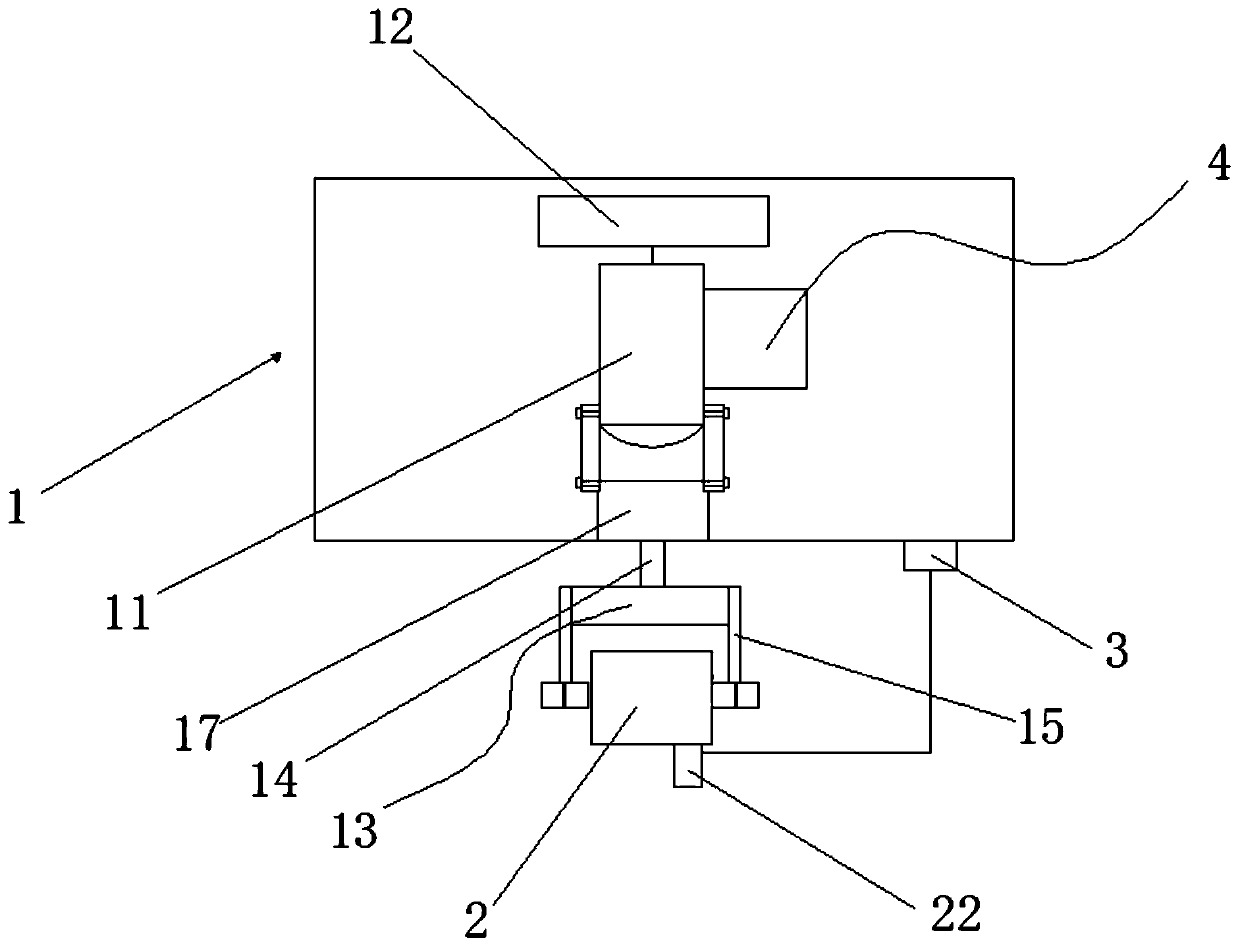

[0018] refer to Figure 1 to Figure 3 , the rolling quality monitoring device at the rolling discharge port in real time, including a device main body 1 and a rolling discharge port 2, the device main body 1 is arranged above the rolling discharge port 2, and the outside of the device main body 1 is provided with a positioner 13, a control The switch 3 and the detection window 17, the positioner is connected to the main body 1 of the device through the screw rod 14, the magnet block 16 is arranged inside the positioner 13, and the positioning clips 15 are arranged on both sides of the outside of the positioner 13, and the positioning clips 15 are connected to the rolling discharge port 2 On both sides, a high-speed high-definition camera 11, a warning signal device 4, and a computer 12 are respectively arranged inside the device main body 1. One end of the high-speed high-definition camera 11 is connected to the detection window 17, and the other end of the high-speed high-defi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com