Bottle body cleaning device for cosmetic production

A technology for cleaning devices and cosmetics, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., capable of solving problems such as bottle damage and equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

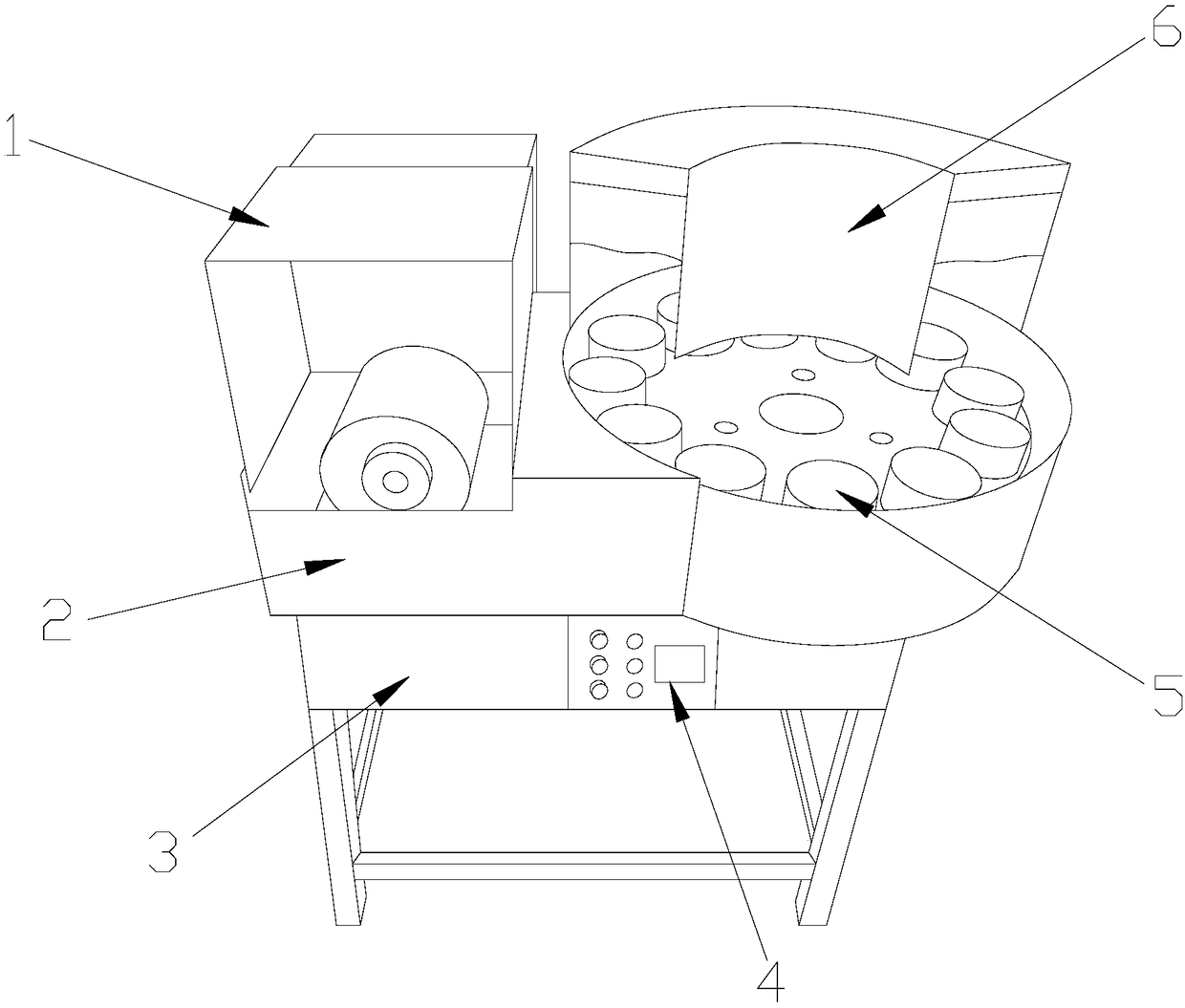

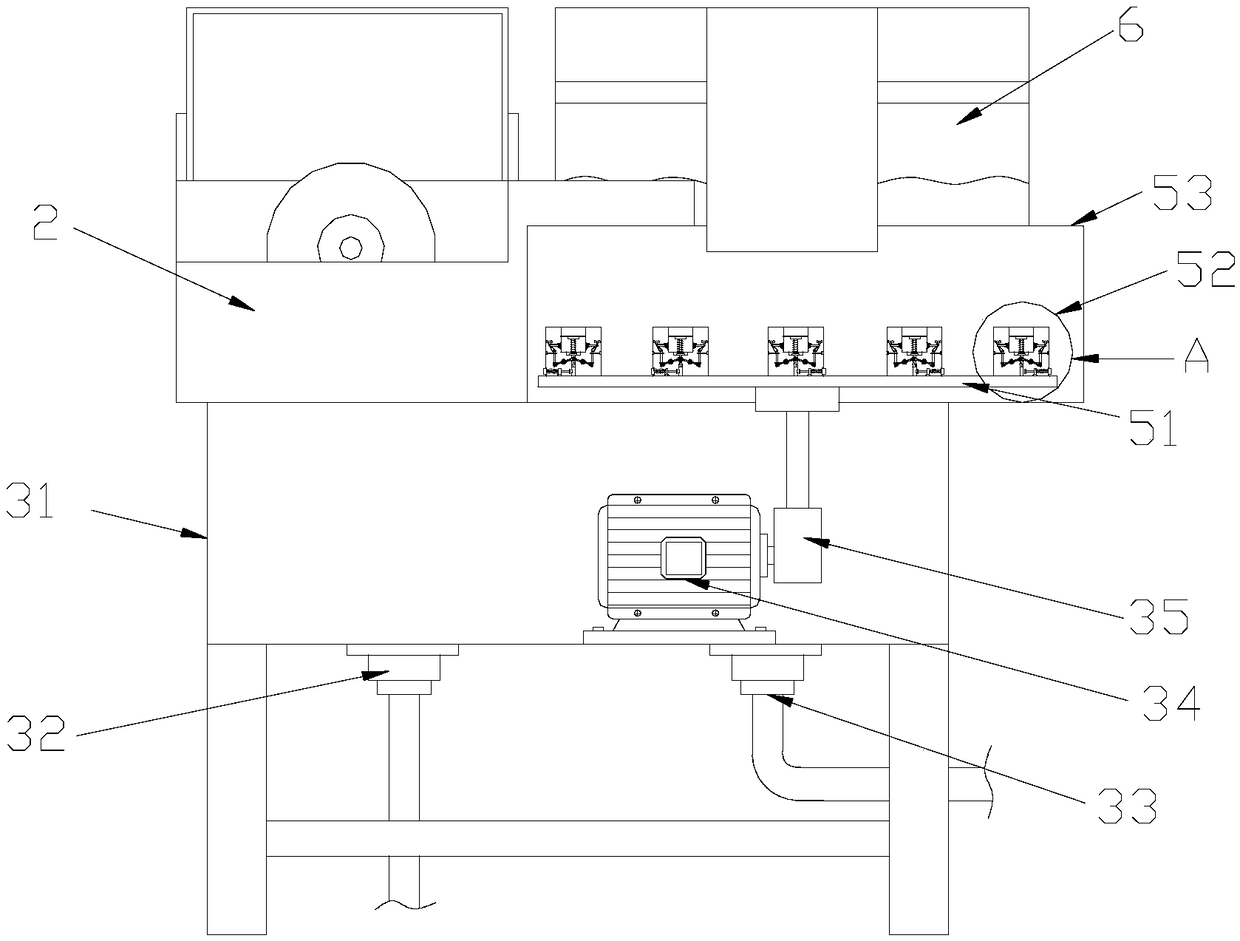

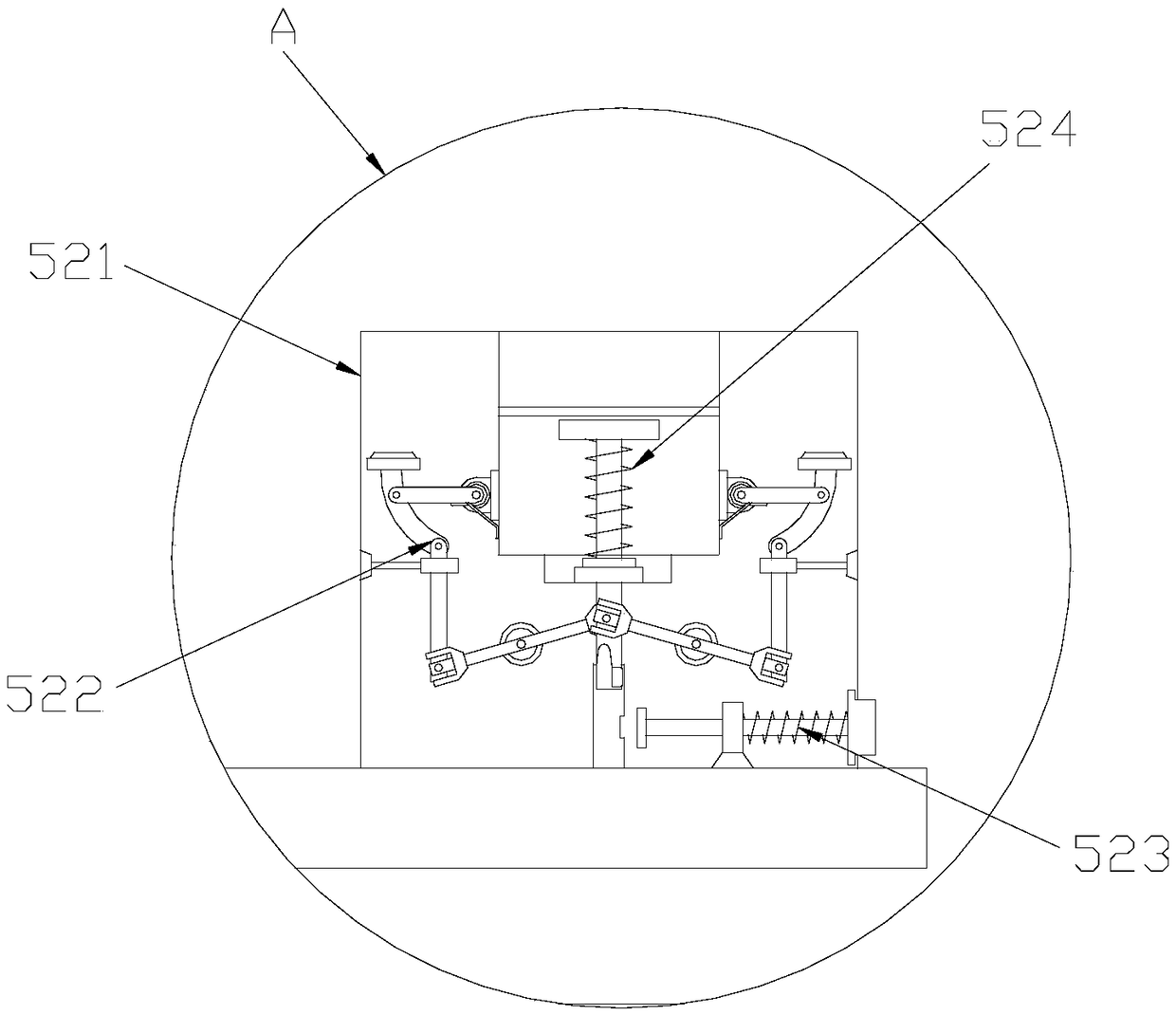

[0020] Such as Figure 1-Figure 5 As shown, the present invention provides a bottle cleaning device for cosmetic production, the structure of which includes a cleaning protective cover 1, a brush cleaning mechanism 2, a cleaning equipment support 3, an electrical controller 4, a bottle rotating device 5, a bottle spraying Structure 6, the electrical controller 4 is bolted to the middle of the front of the cleaning equipment bracket 3, the brush cleaning mechanism 2 is mechanically connected to the left end of the upper surface of the cleaning equipment bracket 3, and the cleaning protective cover 1 is welded to the brush cleaning mechanism 2 Above, the bottle rotating device 5 is installed on the right side of the brush cleaning mechanism 2, the bottle spraying structure 6 is located above the bottle rotating device 5, and the cleaning equipment support 3 is composed of a support shell 31, a drain pipe 32, The water inlet pipe 33, the drive motor 34, and the motor transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com