High-strength composite stranded wire with trapezoidal section and one-step preparation method thereof

A composite material, trapezoidal section technology, used in textiles, papermaking, textile cables, etc., can solve the problem of low effective utilization of cross-sectional area, and achieve the effect of improving effective utilization, increasing bearing capacity, and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] Such as Figure 1-8 shown.

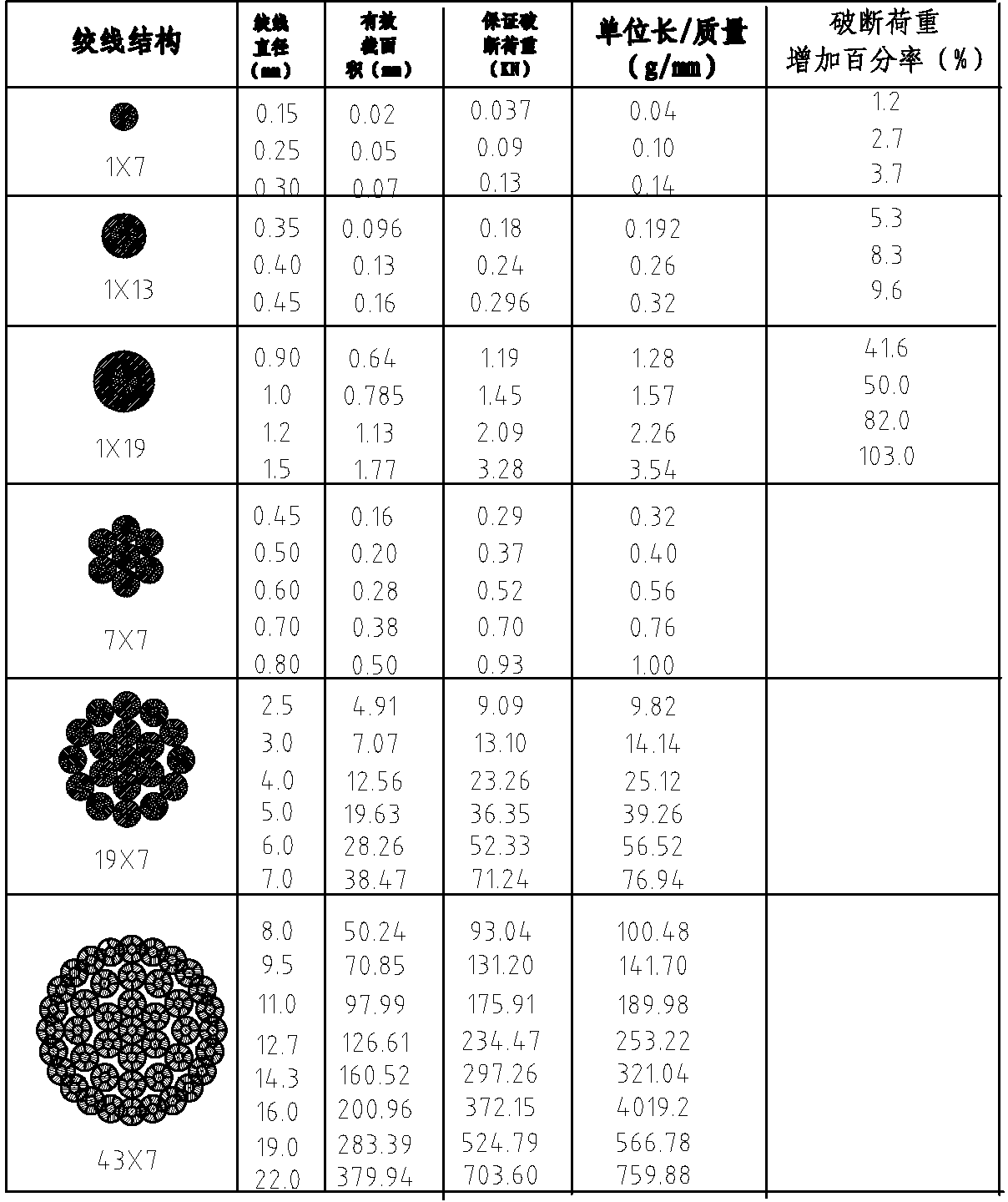

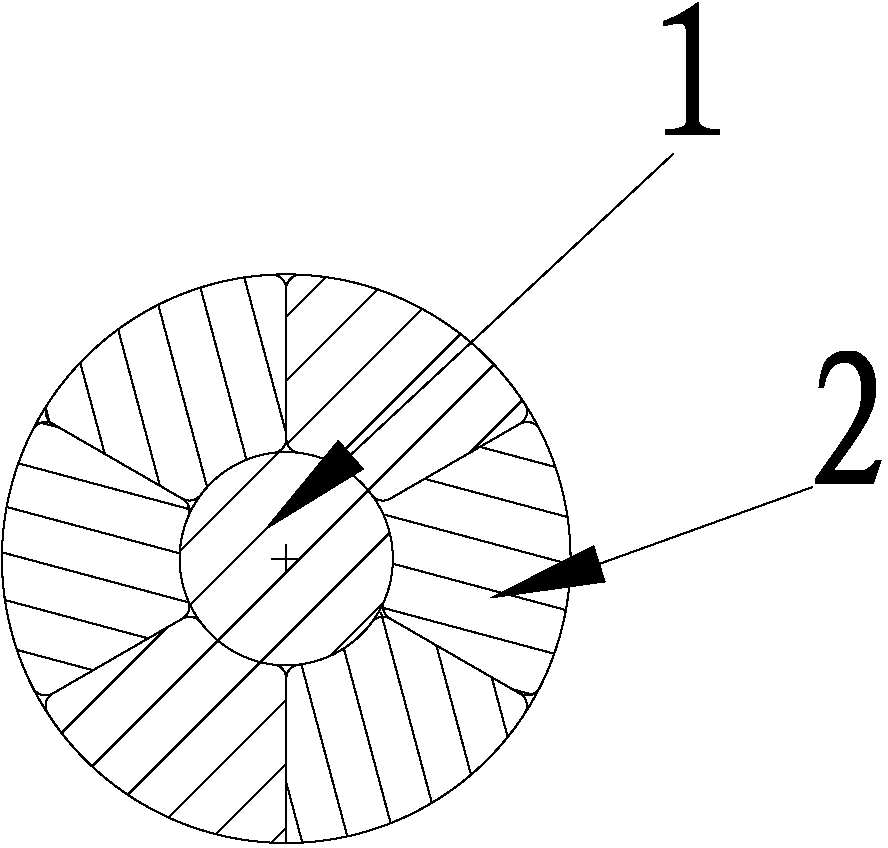

[0033] A high-strength composite stranded wire with a trapezoidal cross-section, which can be divided into 7 single strands ( image 3 ), 13 single strands ( Figure 4 ), 19 single structures ( Figure 5 ), and 7 strands ( Image 6 ), 19 shares ( Figure 7 ) or 43 shares ( Figure 8 ) structure of multi-strand composite strand structure, figure 1 Lines 1-3 in the middle correspond to 7, 13, and 19 strands of single-strand composite material strands, and rows 4, 5, and 6 respectively correspond to multi-strand composite strands of 7 strands, 19 strands, and 43 strands. In specific implementation, the single-strand composite material core wire can be surrounded by a cylindrical core wire 1 and several (6 single-layer, 12 second-layer, 18 third-layer) around the cylindrical core wire 1. The cross-section aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com