Foldable type rotary cotton yarn mop and mop bucket

A rotating mop and foldable technology, which is applied in the direction of cleaning carpets, cleaning floors, cleaning equipment, etc., can solve the problems of complex extrusion structure, high labor intensity, and difficult production and processing, and achieve stable and reliable spin dehydration and improve work efficiency , the effect of solving the difficulty of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

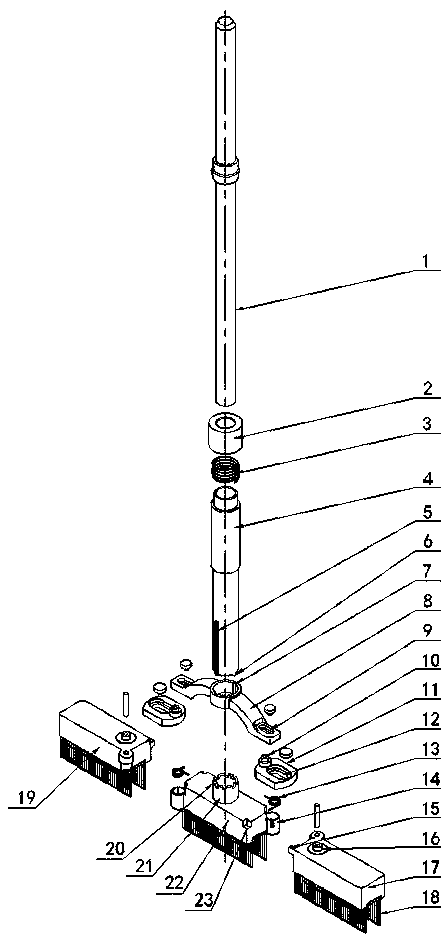

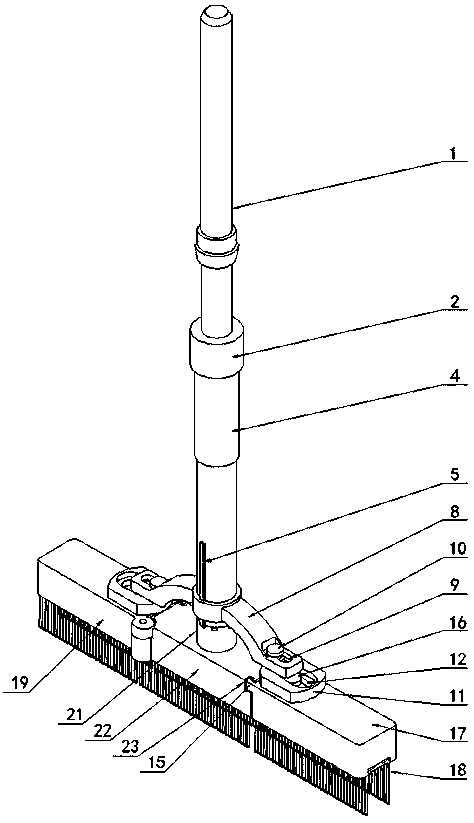

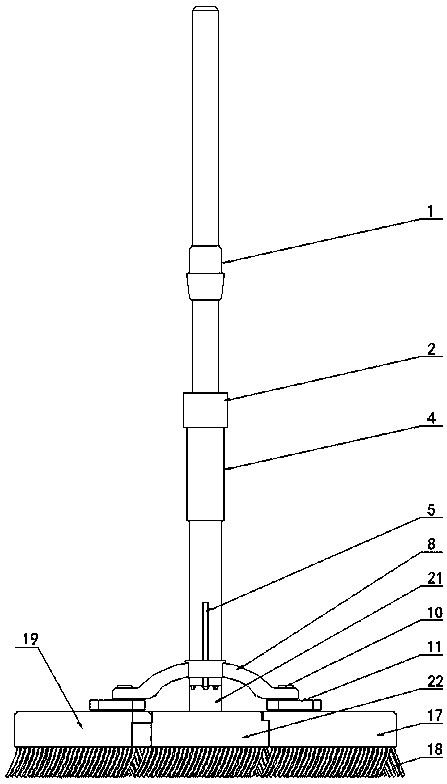

[0020] Figure 1 to Figure 8 As shown, it is a specific embodiment of the invention to create a foldable rotary cotton yarn mop and a mop bucket, a folding rotary cotton yarn mop, including a rotary mop rod 1, a fixed carriage frame 22, left and right carriage frames 19, 17, corresponding fixed The wiper 18 on the left and right pallet racks 19, 17 and the fixed pallet rack 22 and the pallet rotation and folding mechanism, the wiper 18 can be cotton yarn, cloth strips or other cleaning supplies, and the rotary mop rod 1 is fixedly connected to the fixed mop On the fixed seat 21 of the plate frame 22, the opposite corners of the fixed carriage frame 22 are correspondingly provided with hinge seats 14, and the left and right carriage frames 19 and 17 are correspondingly hinged on the hinge seat 14 through the torsion spring 13 and can be elastically reset. The plate frames 19 and 17 can be automatically reset by the torsion spring 13. The rotating and folding mechanism of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com