Effective culture and differentiation medium for indica rice anther

A technology for differentiation culture medium and culture medium, applied in the field of agricultural science, can solve the problems of low efficiency of anther culture of indica rice, low differentiation rate of callus green seedlings, limitation of efficient application of indica rice, etc., so as to improve the differentiation rate of green seedlings and improve rice The effect of flower cultivation efficiency and metabolic rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Prepare the culture medium with the following formula:

[0017] KNO 3 1950mg / L, NH 4 NO 3 1650mg / L, KH 2 PO 4 171mg / L, CaCl 2 2H 2 O 455mg / L, MgSO 4 ·7H 2O 370mg / L, EDTA disodium 37.5mg / L, FeSO 4 ·7H 2 O 27.5mg / L, MnSO 4 4H 2 O 22.5mg / L, ZnSO 4 ·7H 2 O 9mg / L, H 3 BO 3 6.3mg / L, KI 0.83mg / L, CuSO 4 ·5H 2 O 0.025mg / L, Na 2 MoO 4 2H 2 O 0.25mg / L, CoCl 2 ·6H 2 O 0.025mg / L, Inositol 100mg / L, Glycine 2.0mg / L, Methionine 180mg / L, Niacin 0.75mg / L, Leucine 3.0mg / L, Valine 18mg / L, Vitamin B 1 0.3mg / L, vitamin B 6 0.6mg / L, vitamin E 0.5mg / L, vitamin B 12 3.0mg / L, naphthaleneoxyacetic acid 0.25mg / L, p-aminobenzoic acid 0.5mg / L, sucrose 45g / L, calcium pantothenate 5mg / L, AgNO 3 8mg / L, seaweed polysaccharide 5g / L, NAA 3.5mg / L, ZT 3.0mg / L, IBA 4.0mg / L, 2-IP 2.0mg / L, salicylic acid 0.8mg / L enzyme hydrolyzed casein 1.0g / L L, pH 5.8.

[0018] The anther calli of the Indica rice varieties Xianhui 207, 9311, and Minghui 63 were selected as donors. When the...

Embodiment 2

[0021] Prepare the culture medium of following formula (the preferred addition ratio of phytohormone):

[0022] KNO 3 1950mg / L, NH 4 NO 3 1650mg / L, KH 2 PO 4 171mg / L, CaCl 2 2H 2 O 455mg / L, MgSO 4 ·7H 2 O 370mg / L, EDTA disodium 37.5mg / L, FeSO 4 ·7H 2 O 27.5mg / L, MnSO 4 4H 2 O 22.5mg / L, ZnSO 4 ·7H 2 O 9mg / L, H 3 BO 3 6.3mg / L, KI 0.83mg / L, CuSO 4 ·5H 2 O 0.025mg / L, Na 2 MoO 4 2H 2 O 0.25mg / L, CoCl 2 ·6H 2 O 0.025mg / L, Inositol 100mg / L, Glycine 2.0mg / L, Methionine 180mg / L, Niacin 0.75mg / L, Leucine 3.0mg / L, Valine 18mg / L, Vitamin B 1 0.3mg / L, vitamin B 6 0.6mg / L, vitamin E 0.5mg / L, vitamin B 12 3.0mg / L, naphthaleneoxyacetic acid 0.25mg / L, p-aminobenzoic acid 0.5mg / L, sucrose 45g / L, calcium pantothenate 5mg / L, AgNO 3 8mg / L, seaweed polysaccharide 5g / L, salicylic acid 0.8mg / L enzyme hydrolyzed casein 1.0g / L, PH 5.8.

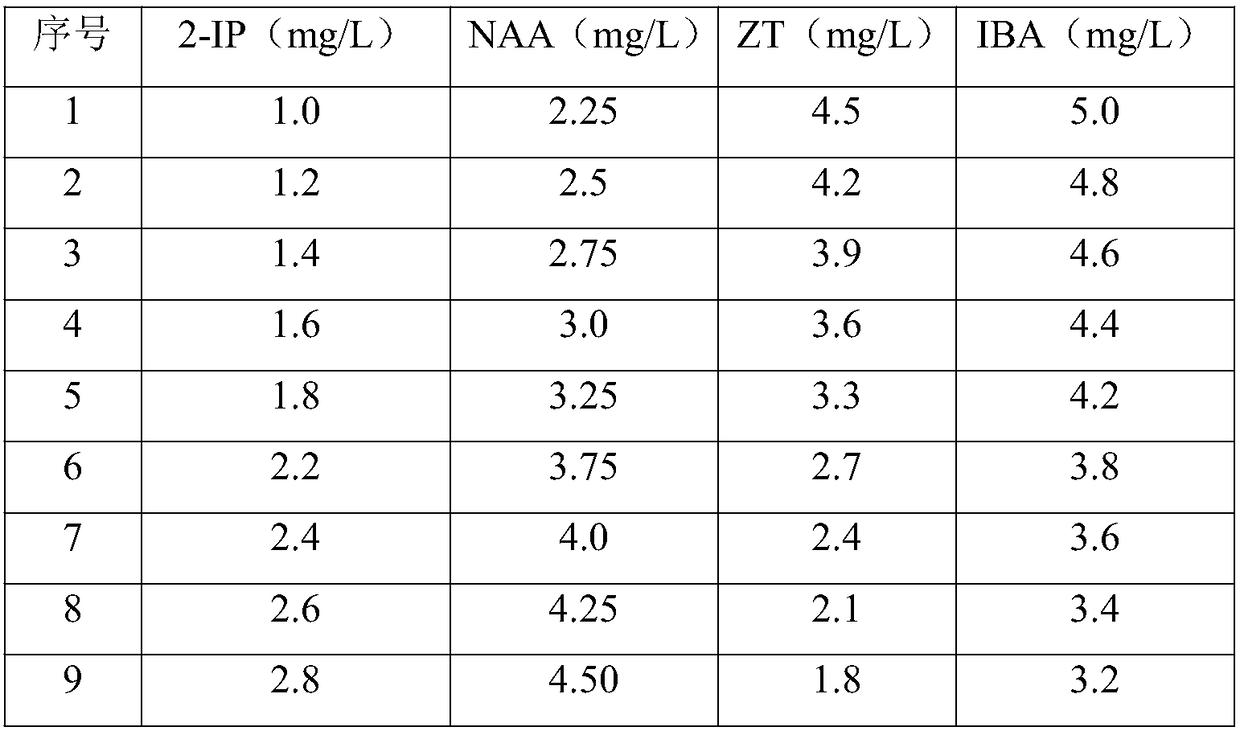

[0023] The concentration ratios of the four plant hormones are shown in Table 1.

[0024] The final concentration ratio of four kind...

Embodiment 3

[0029] Prepare the medium of the following formula (niacin and concentration preferred):

[0030] KNO 3 1950mg / L, NH 4 NO 3 1650mg / L, KH 2 PO 4 171mg / L, CaCl 2 2H 2 O 455mg / L, MgSO 4 ·7H 2 O 370mg / L, EDTA disodium 37.5mg / L, FeSO 4 ·7H 2 O 27.5mg / L, MnSO 4 4H 2 O 22.5mg / L, ZnSO 4 ·7H 2 O 9mg / L, H 3 BO 3 6.3mg / L, KI 0.83mg / L, CuSO 4 ·5H 2 O 0.025mg / L, Na 2 MoO 4 2H 2 O 0.25mg / L, CoCl 2 ·6H 2 O 0.025mg / L, Inositol 100mg / L, Glycine 2.0mg / L, Methionine 180mg / L, Leucine 3.0mg / L, Valine 18mg / L, Vitamin B 1 0.3mg / L, vitamin B 6 0.6mg / L, vitamin E 0.5mg / L, vitamin B 12 3.0mg / L, naphthaleneoxyacetic acid 0.25mg / L, p-aminobenzoic acid 0.5mg / L, sucrose 45g / L, calcium pantothenate 5mg / L, AgNO 3 8mg / L, seaweed polysaccharide 5g / L, NAA 3.5mg / L, ZT 3.0mg / L, IBA 4.0mg / L, 2-IP 2.0mg / L, salicylic acid 0.8mg / L enzyme hydrolyzed casein 1.0g / L L, pH 5.8. The concentration gradient of niacin was set to 0, 0.25, 0.5, 1.0, 1.25, 1.5mg / L respectively. Also select thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com