Comb-cutting type sunflower harvesting method and header

A technology for sunflowers and sunflowers, which is applied to the combing sunflower harvesting method and the field of headers, which can solve the problems of high loss rate of headers, inconvenience, and large damage caused by reels hitting sunflower plates, so as to prevent damage and reduce blows , The effect of simplifying the header structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

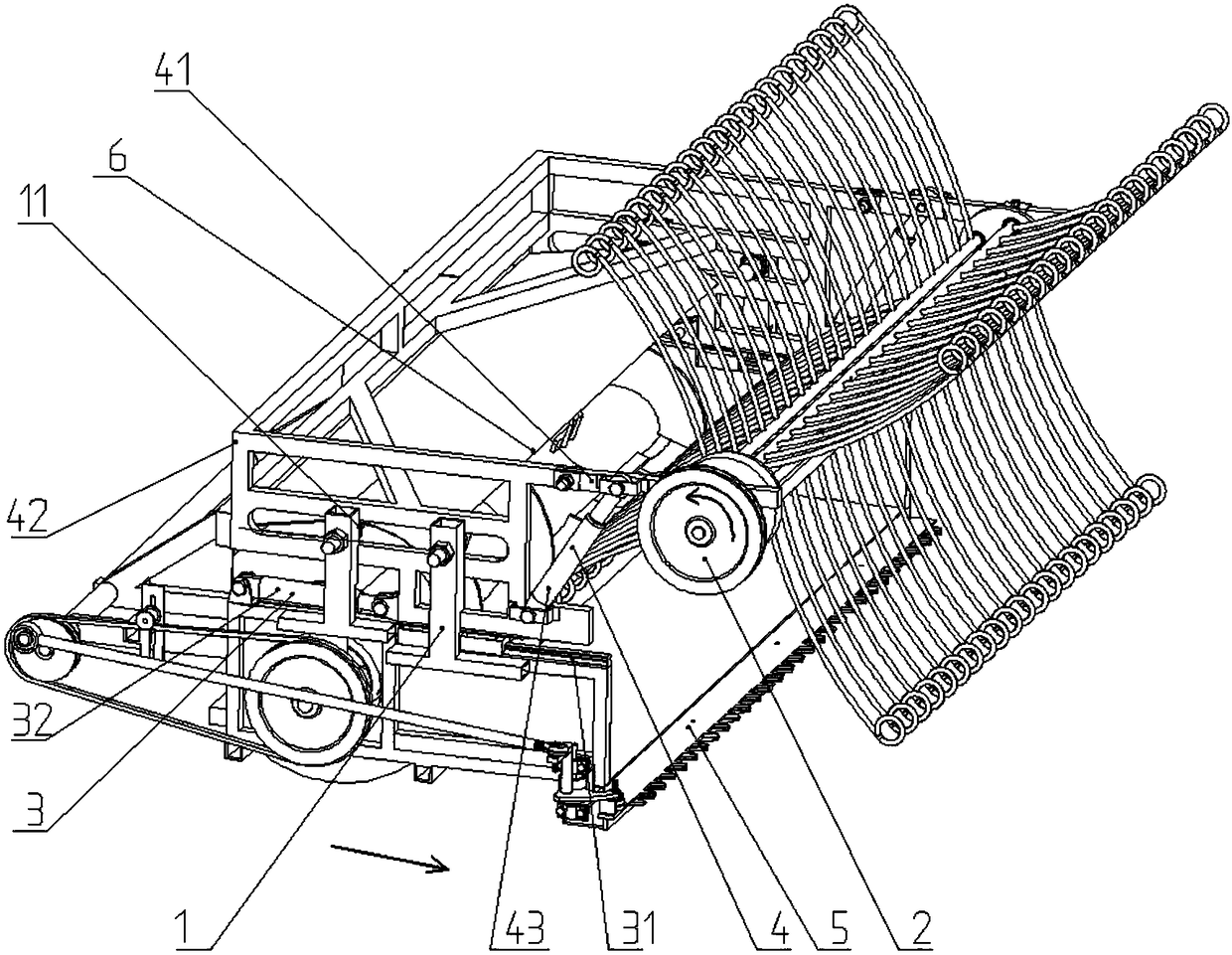

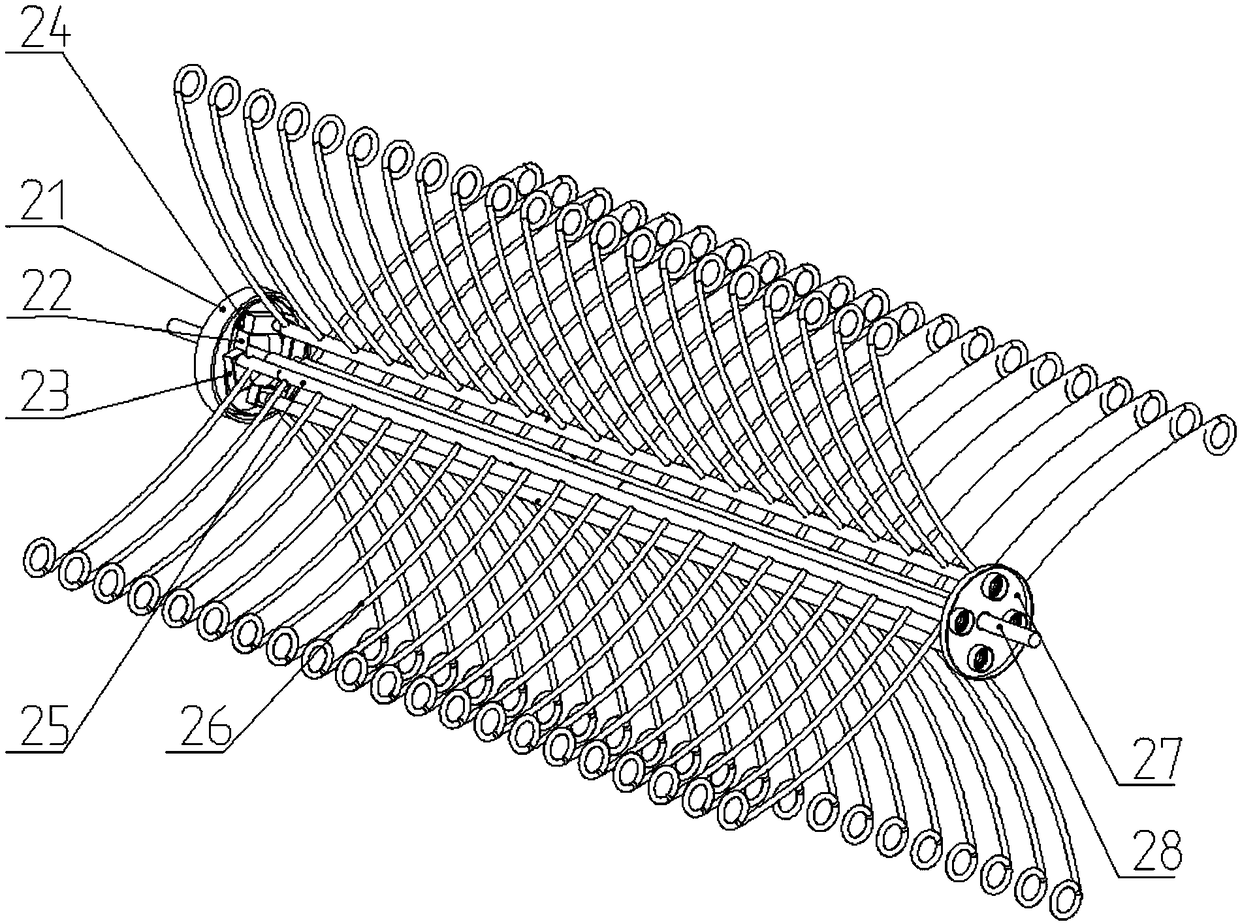

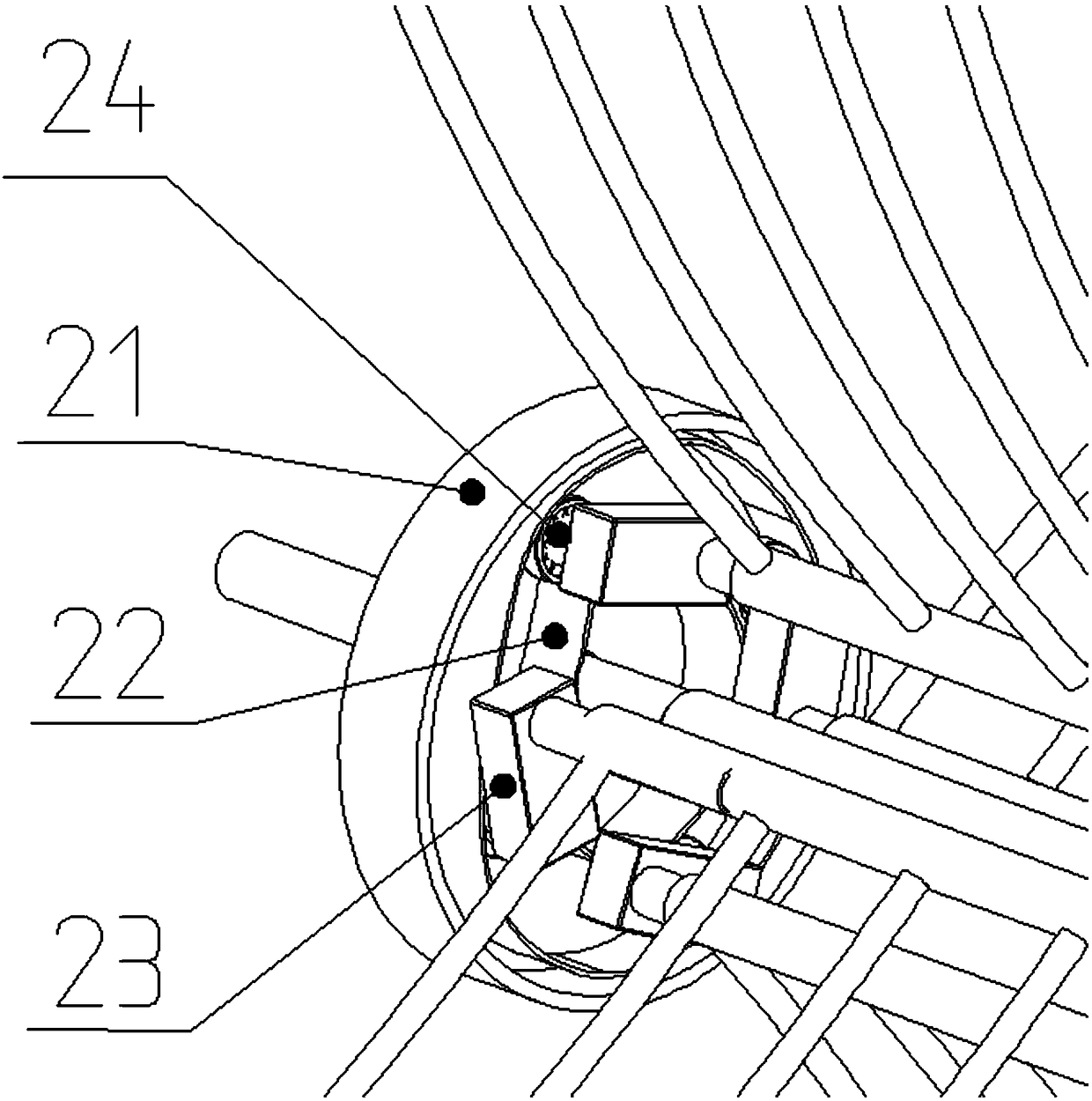

[0026] Such as figure 1 As shown, a comb-type sunflower harvesting header includes a frame 1, a comb-type reeling mechanism 2, a translation mechanism 3, a lifting mechanism 4, a cutting mechanism 5, and a conveying mechanism 6. The comb-type reeling mechanism 2 is set on the translation mechanism 3 by the lifting mechanism 4 or set on the lifting mechanism 4 by the translation mechanism 3. The translation mechanism 3 or the lifting mechanism 4, the cutting mechanism 5 and the conveying mechanism 6 are all set on the frame 1. This embodiment In an example, the comb-type reeling mechanism 2 is arranged on the translation mechanism 3 through the lifting mechanism 4, and the translation mechanism is arranged on the frame 1.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com