Linear vibration motor

A linear vibration and motor technology, applied in the direction of electrical components, electromechanical devices, etc., can solve problems such as unbalanced vibration, affecting the performance and life of linear motors, and high noise of linear motors, achieving vibration balance, improving performance and life, and reducing vibration. Effects of Force and Torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

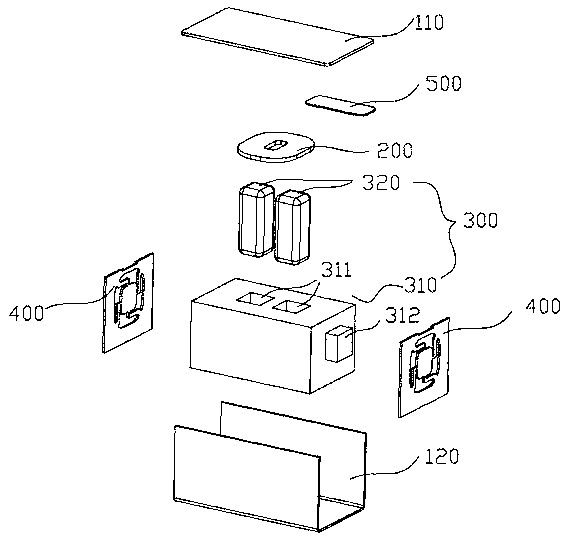

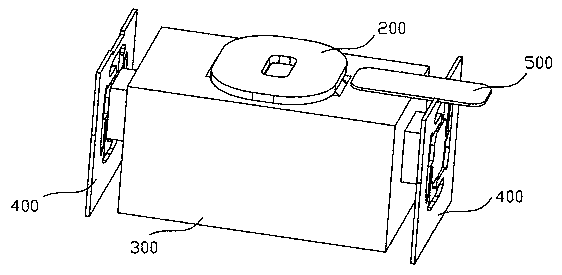

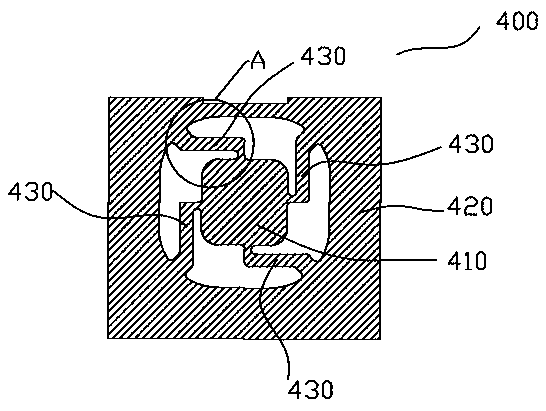

[0024] A linear vibration motor, including a motor housing, a coil 200, a vibrator 300, and an elastic element that suspends the vibrator 300 in the motor housing and provides an elastic restoring force for the vibrator 300; Elastic supports at both ends of the vibration direction, the two ends of the elastic supports are respectively connected to the vibrator 300 and the motor housing; the elastic supports are planar elastic pieces 400; the planar elastic pieces 400 include: an inner plane 410 in the middle, the The inner plane 410 is connected to the vibrator 300; the outer plane 420 located on the periphery, the outer plane 420 is connected to the motor housing; and the elastic arm 430 connecting the inner plane 410 and the outer plane 420, the elastic arm 430 provides elastic recovery for the planar elastic sheet 400 force.

[0025] By designing the elastic element as a plane, the inner plane 410 is connected to the vibrator 300, and the outer plane 420 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com