Outdoor power distribution cabinet

A power distribution cabinet and outdoor technology, applied in substation/power distribution device housing, electrical components, substation/switch layout details, etc., can solve the problem of not being able to block the fire source at the first time, short-circuit spontaneous combustion of internal components, poor heat dissipation, etc. problem, to achieve good heat dissipation effect, solve spontaneous combustion, and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

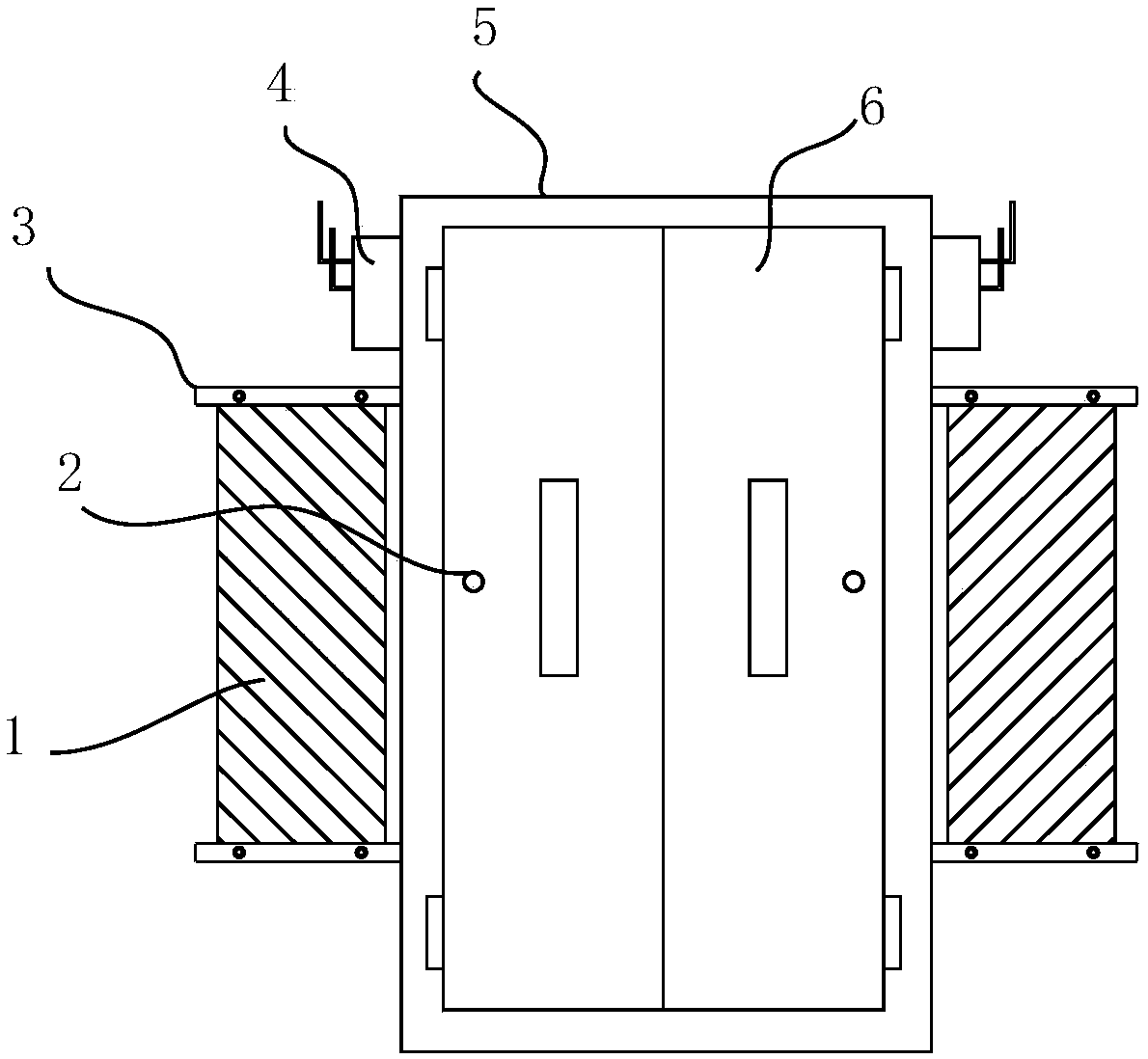

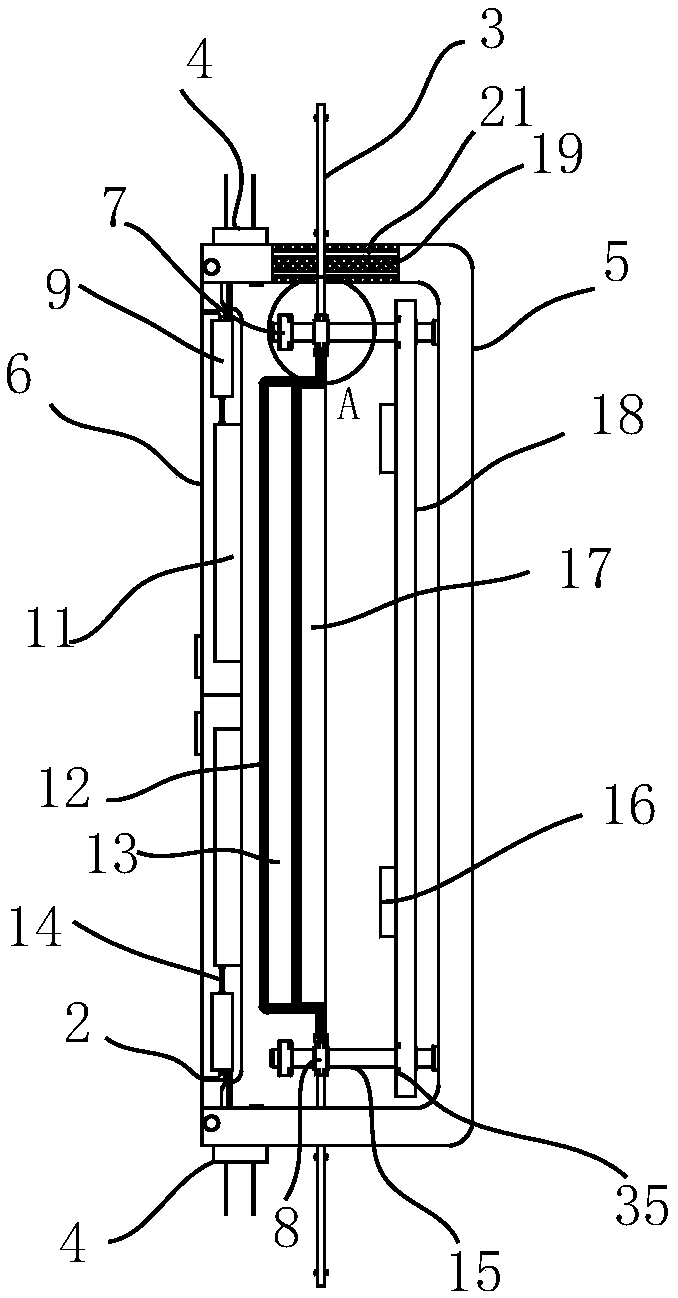

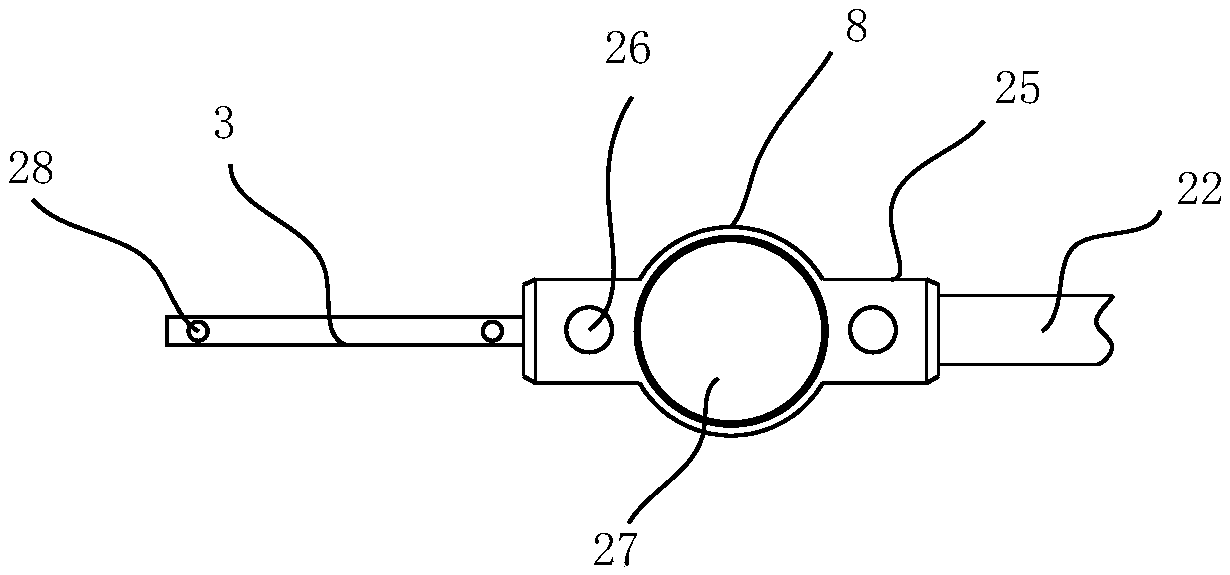

[0026] Such as figure 1 , figure 2 as well as Figure 6 As shown, the outdoor power distribution cabinet includes a cabinet body 5, the front end of the cabinet body 5 has two cabinet doors 6, an electrical chamber is arranged inside the cabinet body 5, and four positioning guide rods 15 are vertically arranged in the electrical chamber. The root of the positioning guide rod 15 is fixedly installed with a power distribution main board 18, and the side of the power distribution main board 18 opposite to the cabinet door 6 is provided with an electronic component 16, and a sliding sleeve 8 is slidably arranged on the four positioning guide rods 15, and the sliding sleeve 8 A fixing part 25 is arranged on each side, and a first magnet 26 is embedded in the outer end of the fixing part 25, and a second magnet 24 is embedded in the other side of the fixing part 25, facing the power distribution board 18 of the second magnet 24. The corresponding third magnet 35 is embedded and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com