Ingot casting quality evaluation method based on numerical simulation

A quality evaluation and numerical simulation technology, applied in the field of metal material casting, can solve the problems of increasing the amount of follow-up sample processing, the inability to evaluate the relationship between the quality of the pouring process steel ingot, and the difficulty of popularization and application, so as to shorten the research and development time, good promotion, and The effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

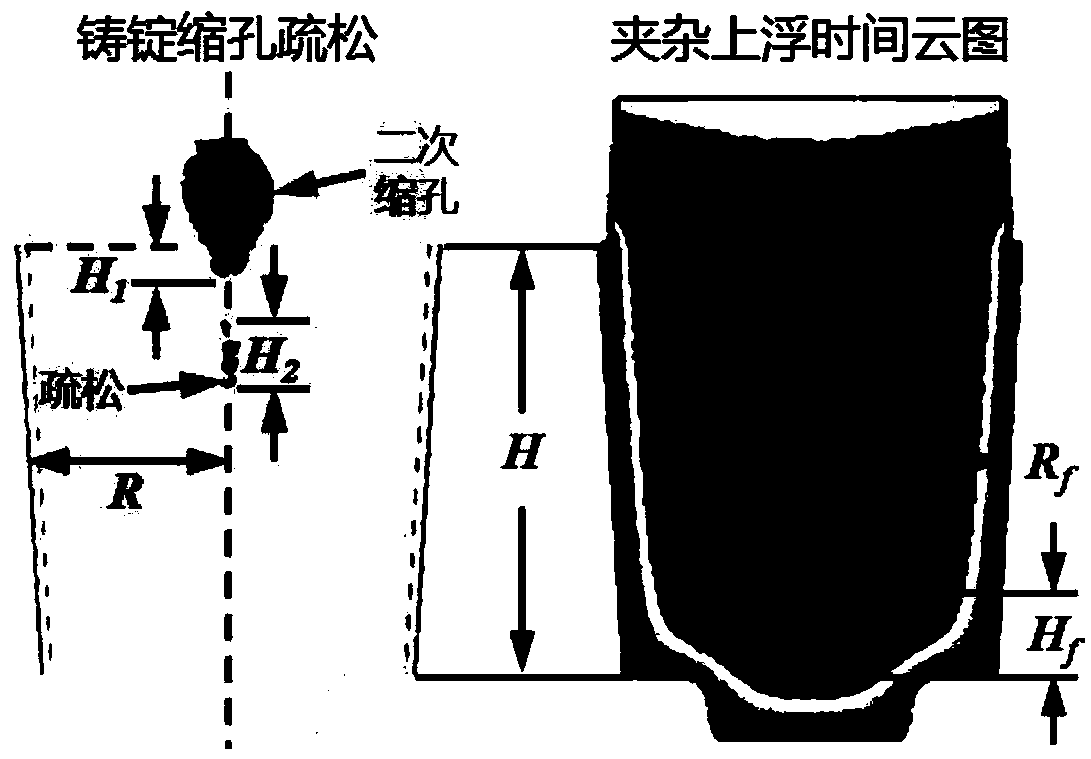

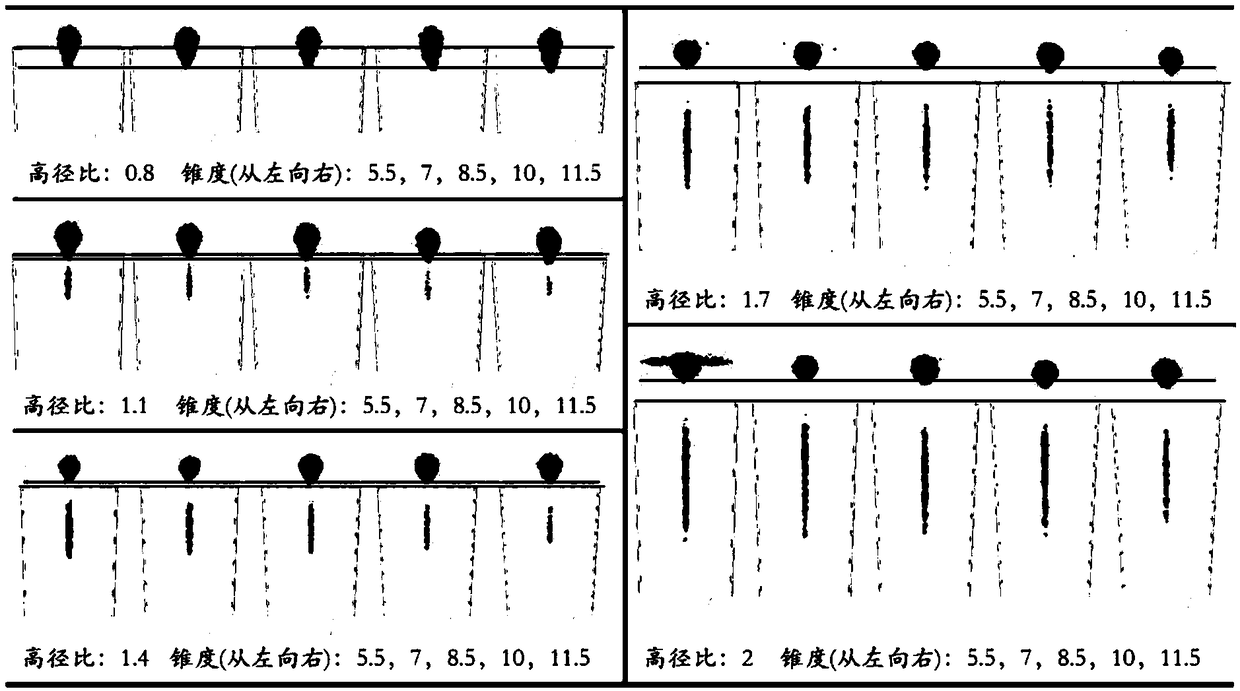

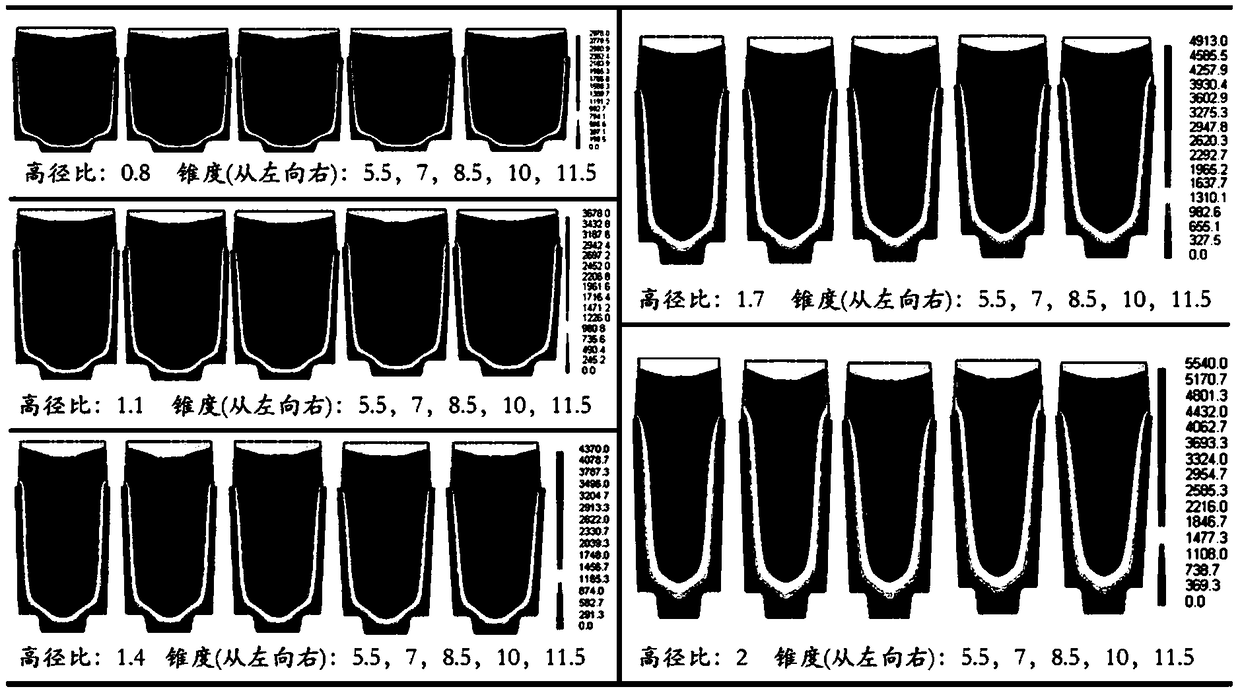

[0029] The selected ingot is 96T steel ingot, the ingot shape (steel ingot mold side mold) is made of cast iron, the size parameters are: height 2889mm, upper radius 1091mm, lower radius 973mm, height-to-diameter ratio 1.4, taper 8.2, volume 9.94m 3 . The pouring alloy material is 70Cr3Mo, the pouring temperature is 1550°C, and the pouring speed is 80Kg / s. The ratio of mold height to diameter and mold taper are selected as factors affecting the quality of ingots. Each factor takes five levels. Among them, the ratio of height to diameter is 0.8, 1.1, 1.4, 1.7 and 2.0, and the taper is 5.5, 7.0, 8.5, 10.0 and 11.5, two factors and five levels of full factorial orthogonal experiments, a total of 25 groups of experiments, while changing the height-to-diameter ratio and taper of the ingot shape, keep the volume of the ingot shape unchanged.

[0030] On the premise that the casting alloy material and casting process parameters remain unchanged, the above 25 groups of tests are simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com