An instrumental detection method for odorous substances in mulberry silk cotton products

A technology for silk floss and products, applied in the field of silk testing, can solve the problems that do not involve the unpleasant smell of silk fabrics and the health hazards of testing personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

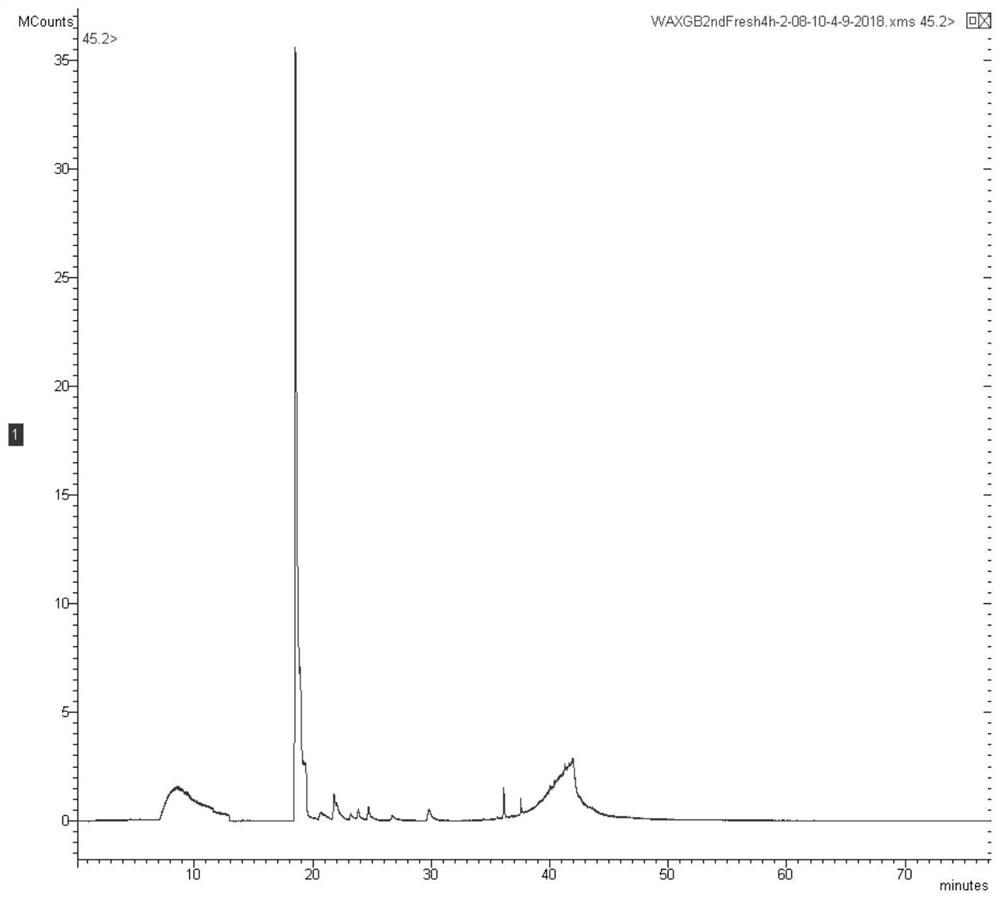

[0050] An instrument detection method for odorous substances in mulberry silk cotton products, comprising the following steps:

[0051] (1) Put 0.5g of the mulberry silk cotton product to be tested in water for 30 minutes, centrifuge and dehydrate at 10000rpm for 5 minutes, put it into an open beaker, place it at 40°C for 4 hours, and then transfer it into a headspace sampling bottle to obtain a sample bottle to be tested ;

[0052] (2) Boil 0.5g non-polluted mulberry silk cotton in boiling water for 30 minutes, dry at 120°C for 20 minutes, then place it in methanol for ultrasonic extraction for 30 minutes, dry it in the air and dry at 120°C for 20 minutes, soak in water for 30 minutes, 10000rpm Centrifuge and dehydrate for 5 minutes, put it into an open beaker, place it at 40°C for 4 hours, and then transfer it into a headspace sample bottle to obtain a blank sample bottle;

[0053] (3) Take the empty bottle, blank sample bottle, and sample bottle to be tested as the sample ...

Embodiment 2

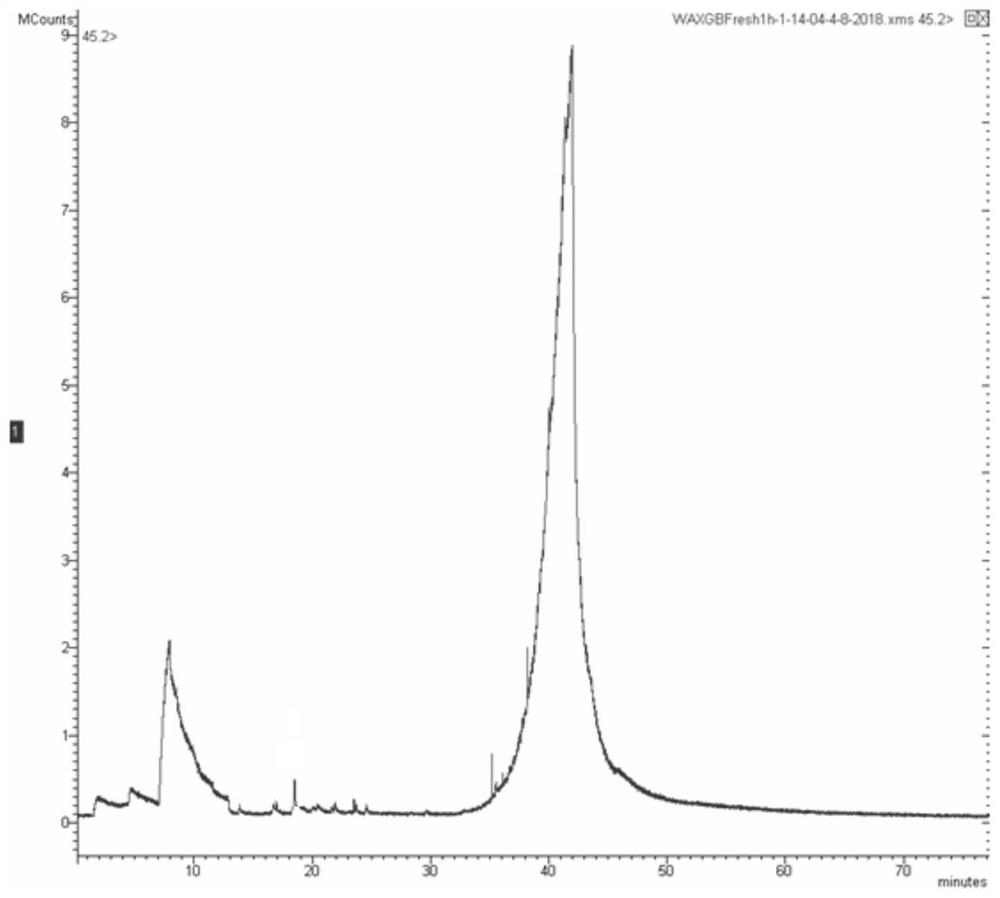

[0062] (1) Boil five 0.50g non-polluting mulberry silk cotton products in boiling water for 30 minutes, dry them at 120°C for 20 minutes, then place them in methanol for ultrasonic extraction for 30 minutes, dry them in the air and dry them at 120°C for 20 minutes; then soak them in water , After centrifugation and dehydration, place at 40°C for 240 minutes, and then put them into headspace sampling vials respectively to obtain five blank vials;

[0063] (2) Dilute the 1,2-dimethylhydrazine (CAS No: 540-73-8) standard with methanol to obtain standard working solutions with different concentrations, 10μg / mL, 50μg / mL, 200μg / mL, 500μg / mL, 1000μg / mL; 5μL of the standard working solution was injected into each blank vial using a micro syringe to obtain a standard working solution vial, and the concentration of 1,2-dimethylhydrazine in the standard working solution vial was 0.1 mg / kg, 0.5mg / kg, 2mg / kg, 5mg / kg, 10mg / kg;

[0064] (3) Using the empty bottle, blank sample bottle, and ...

Embodiment 3

[0066] According to the method of Example 2, standard working solution sample vials were prepared, in which the concentrations of 1,2-dimethylhydrazine were 1 mg / kg, 5 mg / kg and 50 mg / kg, respectively.

[0067] Take the empty bottle, blank sample bottle, and standard working solution sample bottle as the sampling bottle in turn, and use headspace solid phase microextraction-gas chromatography-mass spectrometry to measure the blank sample chromatogram and standard working curve chromatogram, according to 1,2 -The mass spectrogram, retention time and response value thereof of dimethylhydrazine, obtain mass spectrometry response value, measure 6 times for every sample, then calculate average recovery rate and relative standard deviation, bring into mass spectrometry response value-concentration standard working curve, obtain 1 , the detection concentration of 2-dimethylhydrazine, the results are shown in Table 1, the recoveries of 6 parallel samples of all the levels of addition a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com