Range hood with bellows for noise filtering function

A technology for noise filtering and range hoods, applied in the direction of removing oil fumes, mechanical equipment, machines/engines, etc., can solve the problems of increasing the size of the range hood, increasing the overall weight of the range hood, etc., to reduce narrow-band noise and broadband noise, and minimize Minimized size design, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

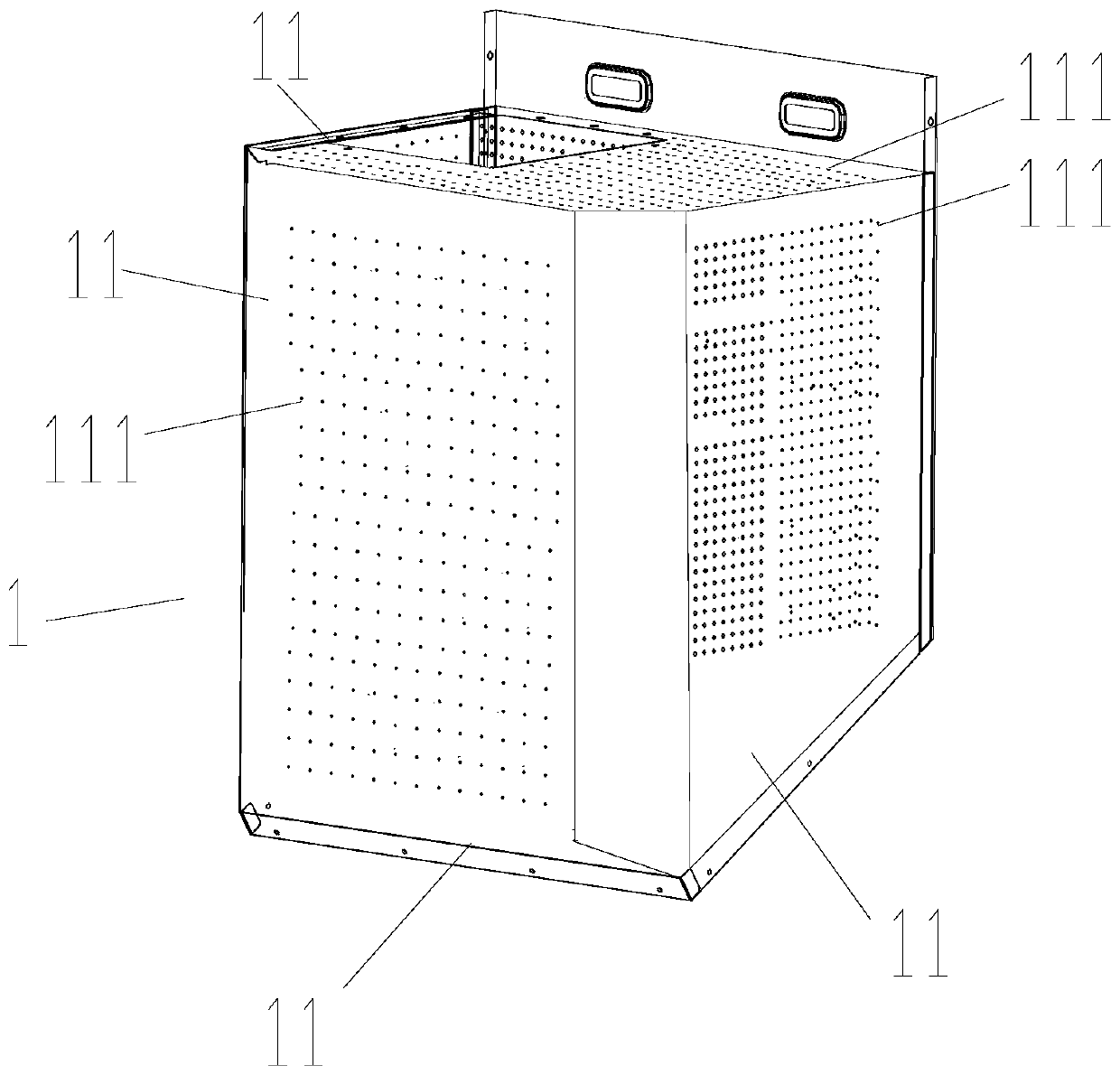

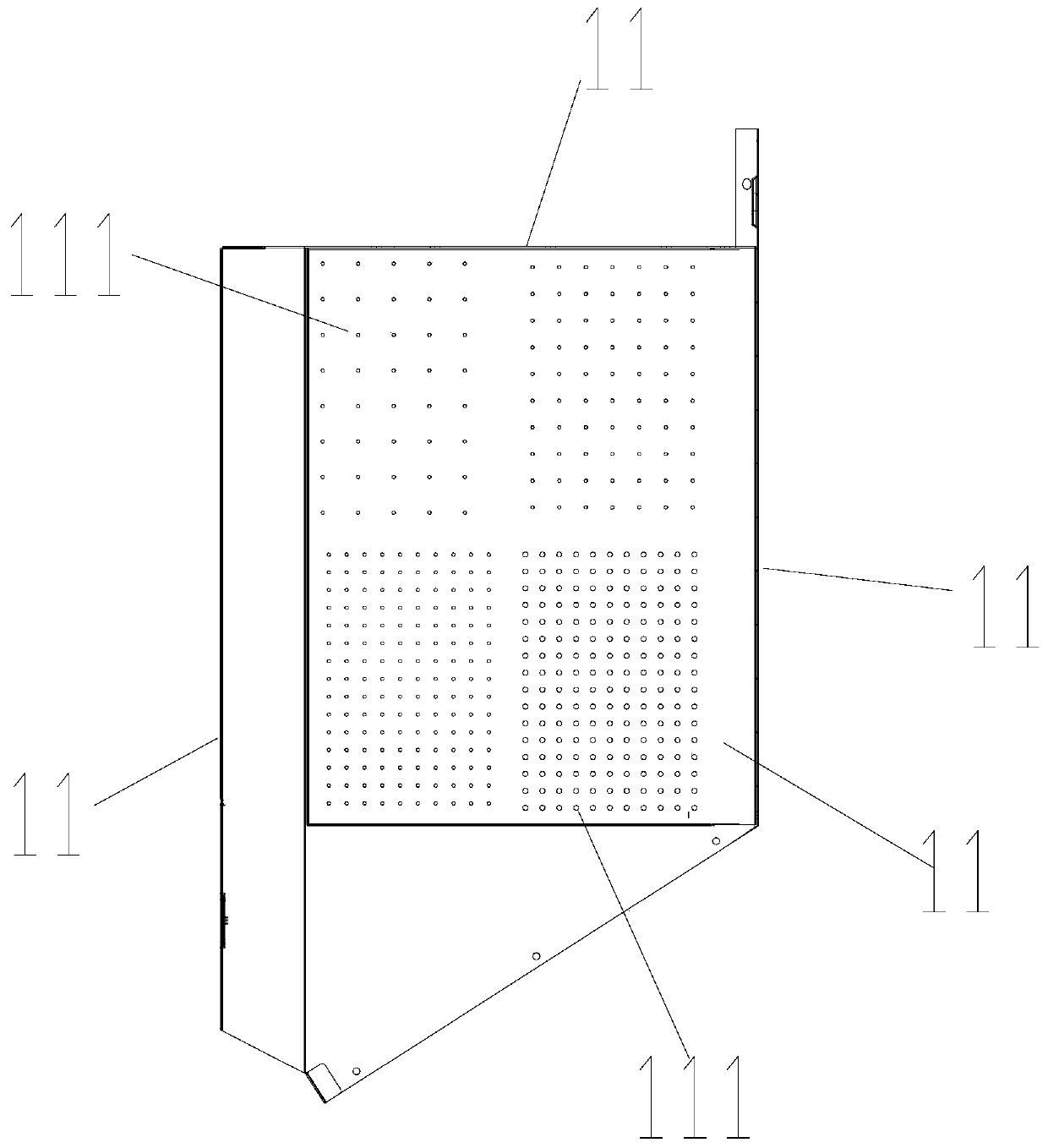

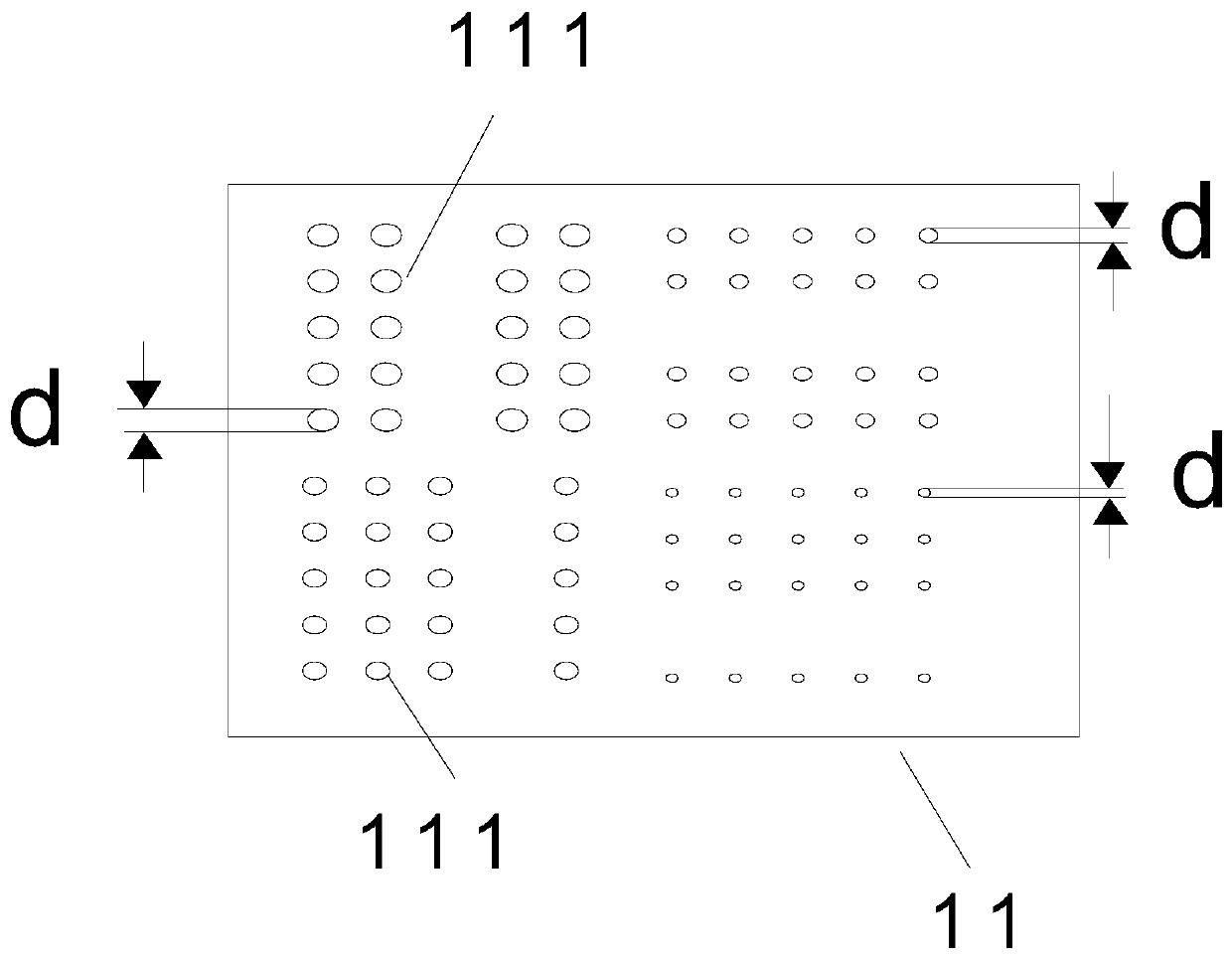

[0042] A range hood with a bellows for noise filtering, such as Figure 1-4 As shown, the main body of the hood and the bellows 1 capable of eliminating multi-frequency noise are provided, and the bellows 1 is assembled inside the main body of the hood. The bellows 1 is formed by splicing a plurality of panels 11, and the panels 11 are distributed with a plurality of through holes 111 for eliminating noise.

[0043] The main body of the hood is provided with an outer cover 2 , and the bellows 1 is assembled inside the outer cover 2 . There are multiple panels 11 , and multiple panels 11 are spliced to form a continuous and limited enclosure around the bellows 1 . Specifically, there are five panels 11 in this embodiment, and the five panels 11 are spliced to form a polyhedron with an open bottom.

[0044] It should be noted that the number of panels 11 of the present invention can be 5, or any number of 2 or more, as long as the panels 11 can only be spliced to form a ...

Embodiment 2

[0054] A range hood with a bellows for noise filtering, such as Figure 5 As shown, other characteristics are the same as those in Embodiment 1, except that: the bellows 1 is also provided with a sound-absorbing part 12, and the sound-absorbing part is assembled with the main body of the cigarette machine. The thickness of the sound absorbing part 12 is defined as H 2 , and H 2 ≤0.6H 1 .

[0055] The sound absorbing part 12 of this embodiment is fixed in the gap.

[0056]The density and material of the sound-absorbing part 12 also have an important influence, and sound waves will directly pass through the ultra-low-density sound-absorbing part, and there is no way to increase the friction loss of sound energy. Under high density, the noise sound wave will be reflected directly, and there is no way to enter the hole of the bellows 1 .

[0057] Therefore, the sound absorbing part 12 of the present invention is preferably fiber, PP cotton, polyester fiber, carbon fiber or po...

Embodiment 3

[0060] A range hood with a bellows for noise filtering, such as Figure 6 As shown, other features are the same as those in Embodiment 1, except that the panel 11 of this embodiment is specifically a metal panel 11 . The bellows 1 eliminates noise with a frequency range of 100 Hz to 8000 Hz.

[0061] It should be noted that the panel 11 of the present invention may also be a plastic panel 11 or an alloy panel 11 , and the specific implementation depends on the actual situation.

[0062] The thickness of the panel 11 of the present invention is less than 20 mm, because too thick will increase the weight of the bellows 1 .

[0063] The panel 11 of this embodiment is integrally connected with a strengthening structure 112 . The specific strengthening structure 112 is a reinforcing rib.

[0064] It should be noted that the reinforcing structure 112 of the present invention can also be one of reinforcing ribs, convex or concave, or can be any combination of multiple types. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com