Mechanism for eliminating engaging backlash between oscillating teeth and sliding sheets as well as design method capable of prolonging life of engaging teeth

A movable tooth sliding piece and design method technology, applied to mechanical equipment, belts/chains/gears, transmission parts, etc., can solve problems such as shortening the life of movable tooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

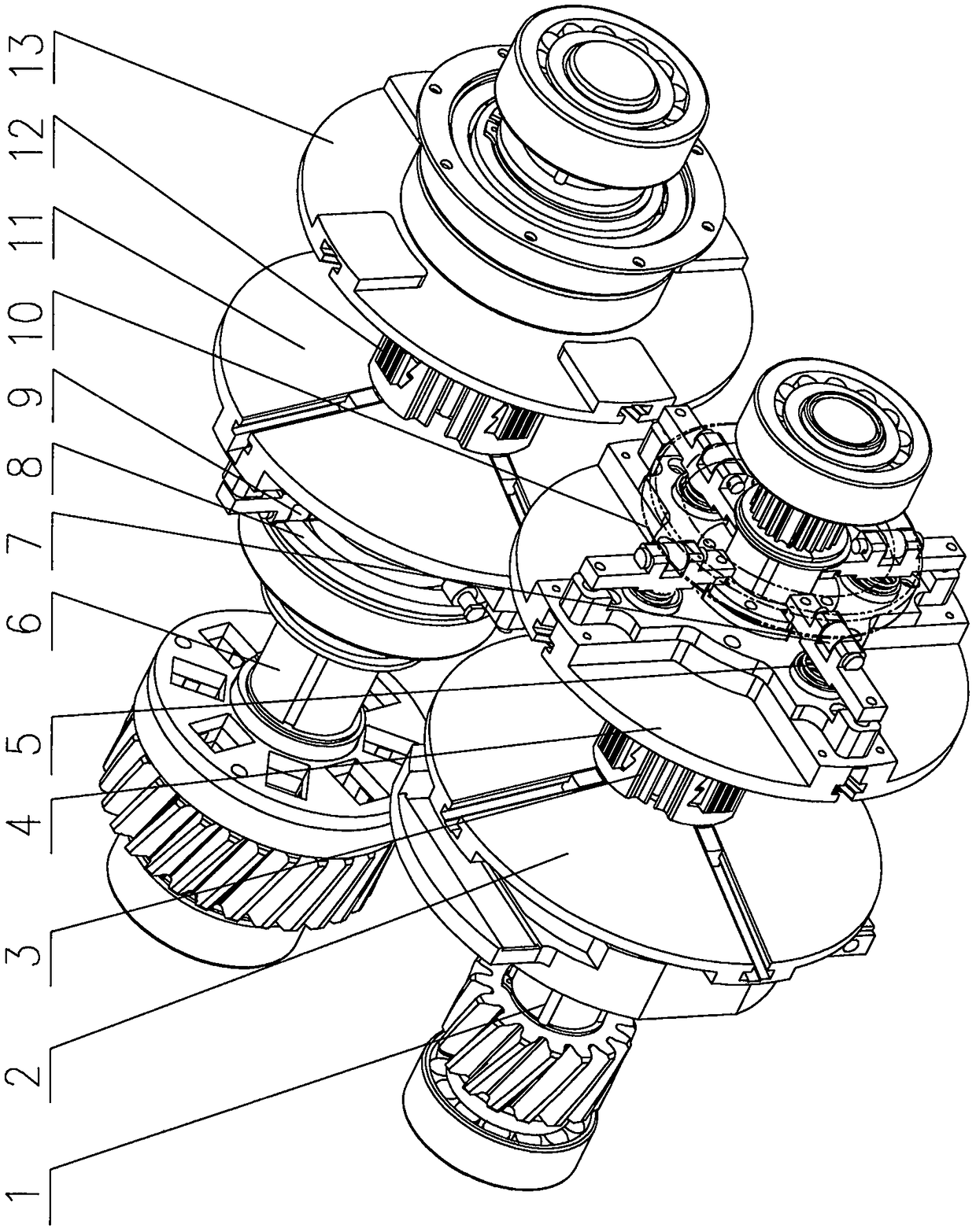

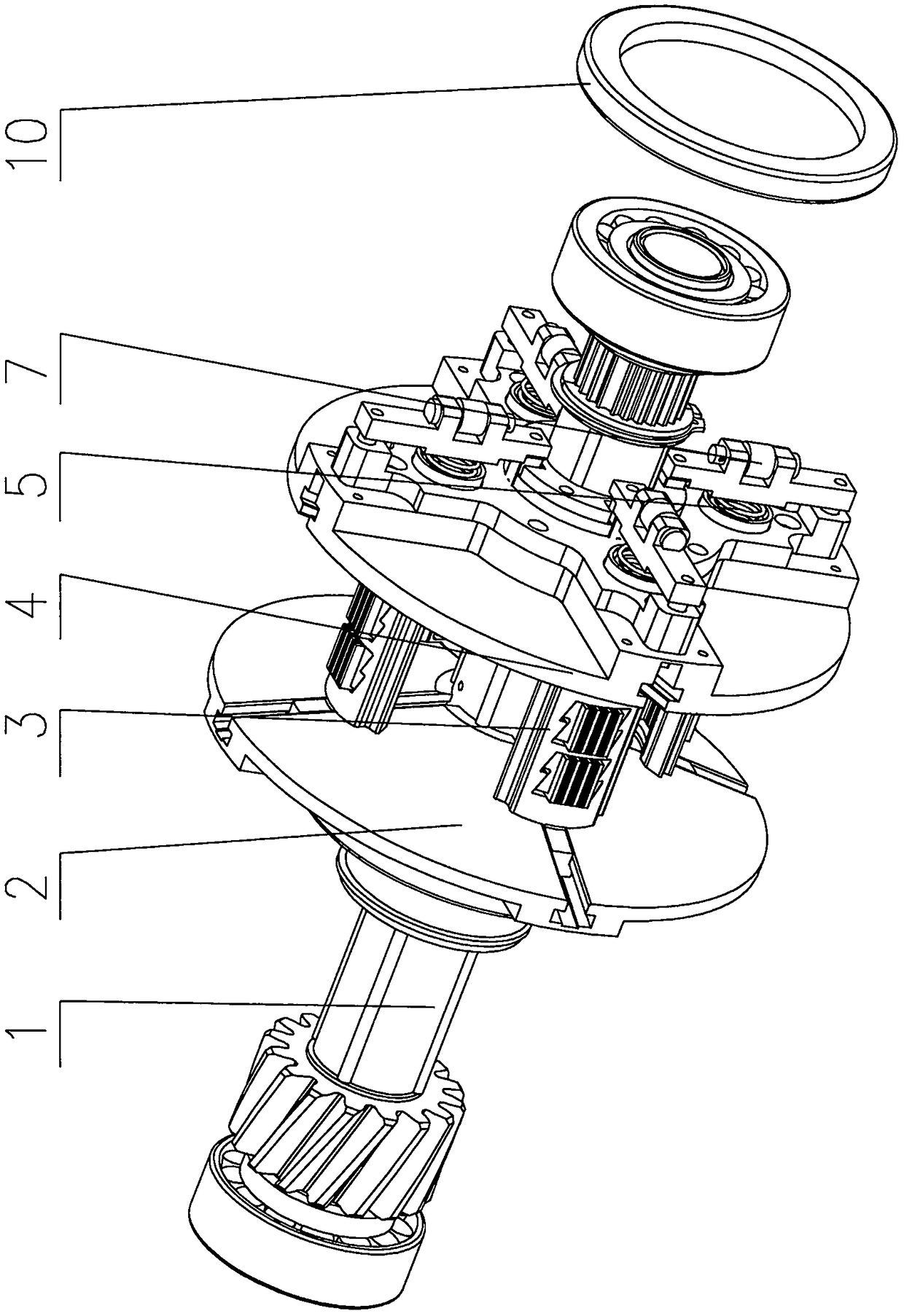

[0054] Specific embodiments of the present invention such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 11 Shown:

[0055] The specific structure of its core part is: through the cooperation of a special wedge-shaped sliding vane warehouse 14 and the wedge-shaped movable tooth unit beam 3, use its axial movement to obtain the circumferential tangential displacement, so as to adjust the circumferential tangential displacement of the sliding vane. To eliminate the meshing gap between the slide plate and the sprocket. For its enlarged view, see: Figure 11 ;

[0056] The detailed structure of relevant parts and components of the present invention and the assembly relationship with the transmission assembly are referred to: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 .

[0057] As shown in the figure: the slide 15 is placed in the wedge-shaped slide bin 14, and the wedge-shaped slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com