Installation and debugging combined tool applied to compressor instrument probe

A technology of installation, debugging, and combination of tools, applied in the direction of manufacturing tools, instruments, measuring devices, etc., can solve the problems of difficulty in guaranteeing, the gap between the instrument probe and the surface of the compressor shaft does not change, and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

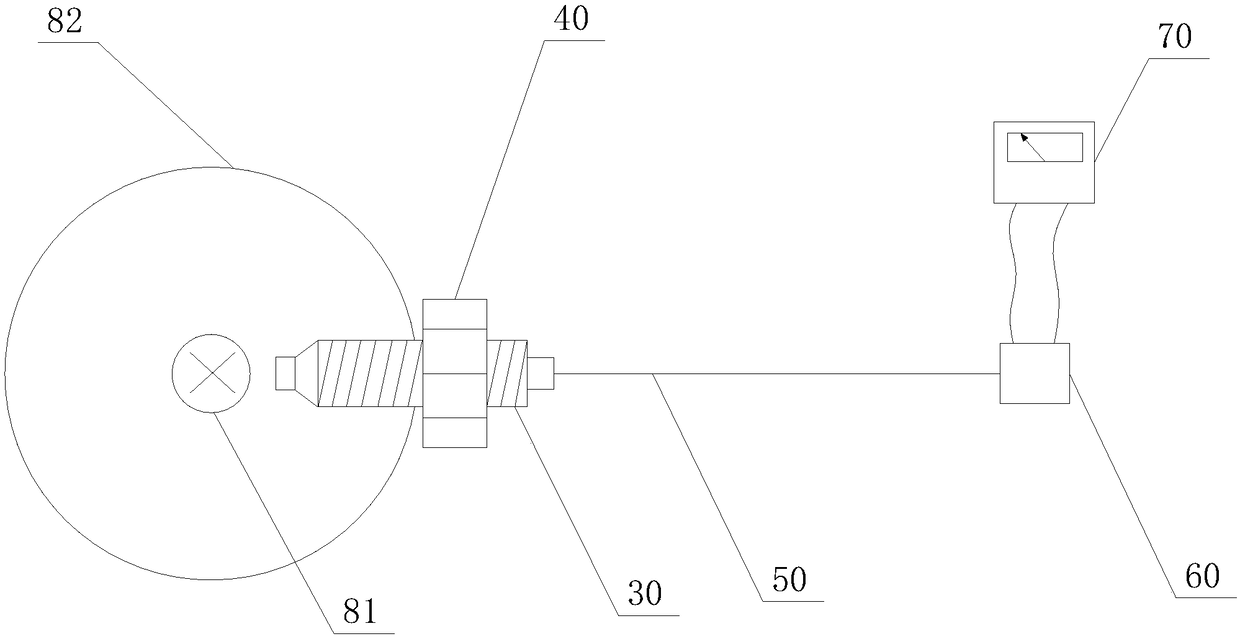

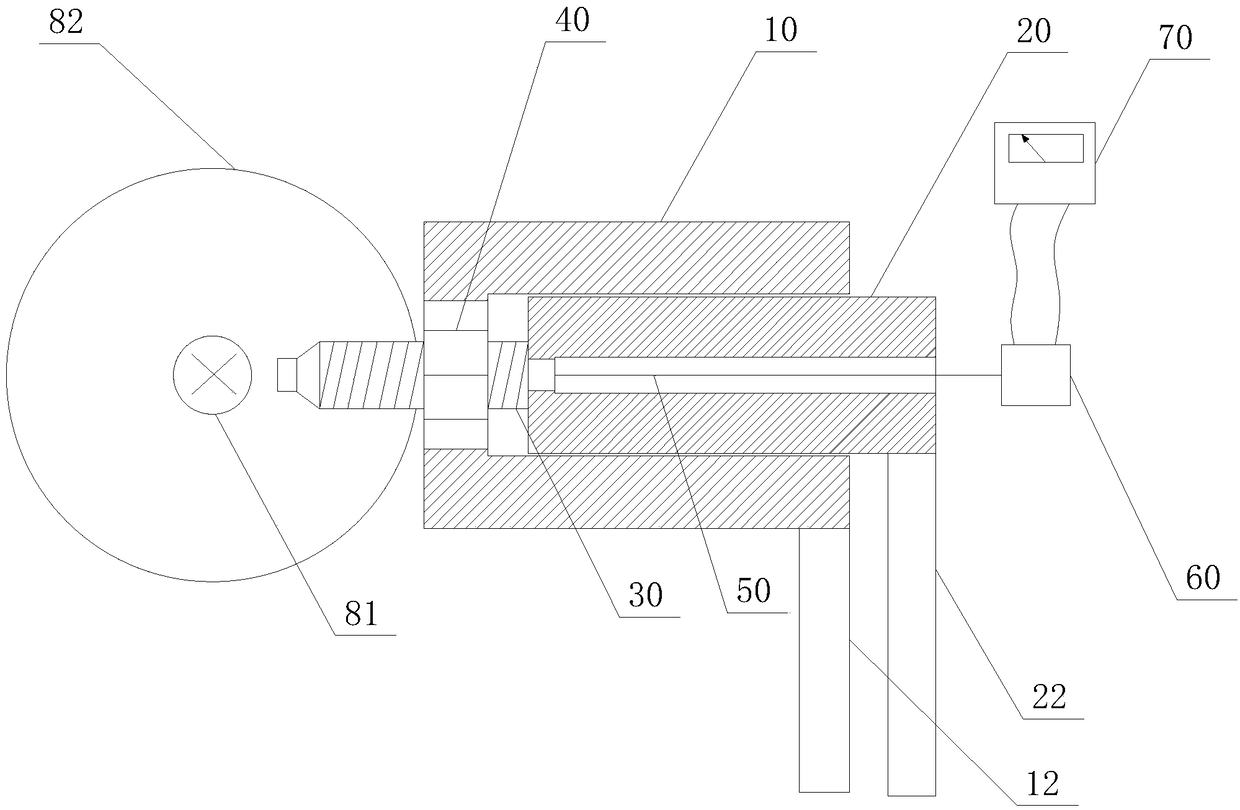

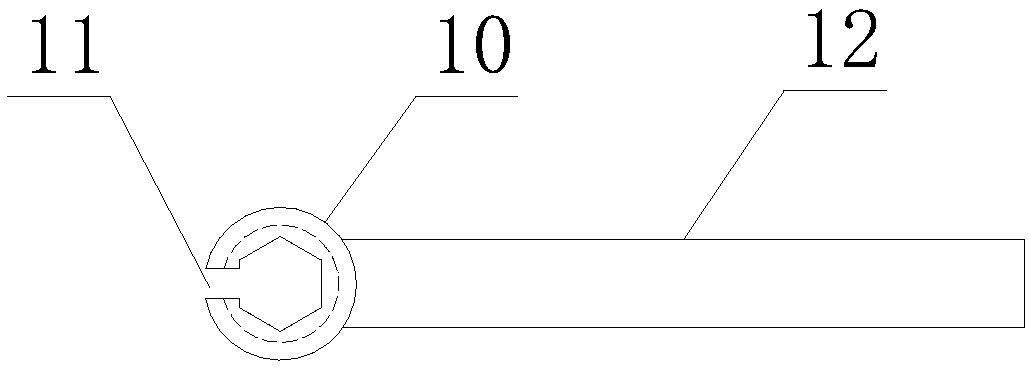

[0026] Such as figure 2 As shown: the present invention includes an outer rotation sleeve 10 and an inner rotation sleeve 20 arranged coaxially, and the outer rotation sleeve 10 is sleeved on a lock nut 40 for fixing the instrument probe 30 and is connected to the The locking nut 40 is engaged to realize the synchronous rotation of the locking nut 40 with the outer rotating sleeve 10, and the inner rotating sleeve 20 is sleeved on the instrument probe 30 and engaged with the instrument probe 30 to realize the described The instrument probe 30 rotates synchronously with the inner rotating sleeve 20 . The present invention can realize that the locking nut 40 fixes the instrument probe 30 without changing the gap between the instrument probe 30 and the side of the compressor shaft 81, so as to ensure that the instrument probe 30 meets the installation tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com