A pipe profile detection method based on three installation points

A shape detection and installation point technology, applied in the direction of measuring devices, instruments, etc., can solve the problem of not truly reflecting the installation angle deviation of the pipe fittings, the gap between the seams, etc., to improve quality reliability and credibility, reduce production costs, reduce The effect of misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

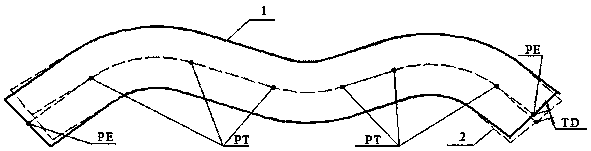

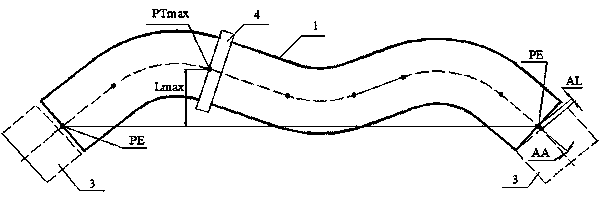

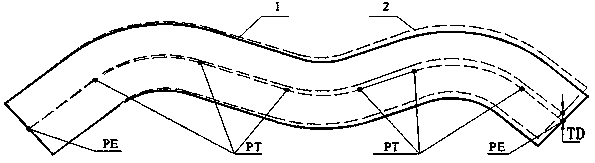

[0049] A method for detecting the shape of a pipe fitting based on three installation points includes a positioning method based on the three installation points, a deviation calculation method and detection requirements. The positioning method based on three installation points includes three installation points and a space positioning method. The three installation points refer to three points closely related to the installation location: the two end points PE of the pipe fitting, and the bending tangent point PTmax of the maximum Lmax on the line connecting the two end points PE. The space positioning method includes three steps: the first step is to determine the space triangle S from the three installation points of the theoretical pipe fittings, and determine the center of gravity G of the triangle S; the second step is to determine the same three installation points of the measured pipe fittings Determine the space triangle S1, and determine the center of gravity G1 of ...

Embodiment 2

[0054] On the basis of Example 1, for a 90°bending pipe fitting, the straight sections at both ends are 100mm and 50mm respectively, and the space coordinates of points on the centerline of the theoretical pipe fitting are T1 (0,100,0), T2 (150,100,0), T3 (200,50,0), T4 (200,0,0), the installation requires an angular deviation of ±3°, and an installation axial clearance of 0.5mm. When measuring the pipe fittings to be tested, the accuracy of the selected measuring equipment is at least 0.5 / 3=0.167mm, and the actual laser vector measuring equipment has an accuracy of 0.001mm, which can be used to measure pipe fittings. The actual measurement coordinates of the points on the centerline of the tested pipe fittings are P1 (0.800, 59.600, 125.000), P2 (90.061, 14.970, 125.000), P3 (112.021, -52.889, 125.000), P4 (88.650, -97.65, 125.000) ).

[0055] Calculation process: use computer calculation, the calculation accuracy is at least 0.5 / 100=0.005mm, the actual choice is 0.001mm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com