A kind of preparation method of multi-principal alloy nanopowder

A multi-principal alloy and nano-powder technology, applied in the direction of nanotechnology, can solve the problems of low production efficiency, high cost, and inability to meet industrial production, and achieve high production efficiency, uniform distribution, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

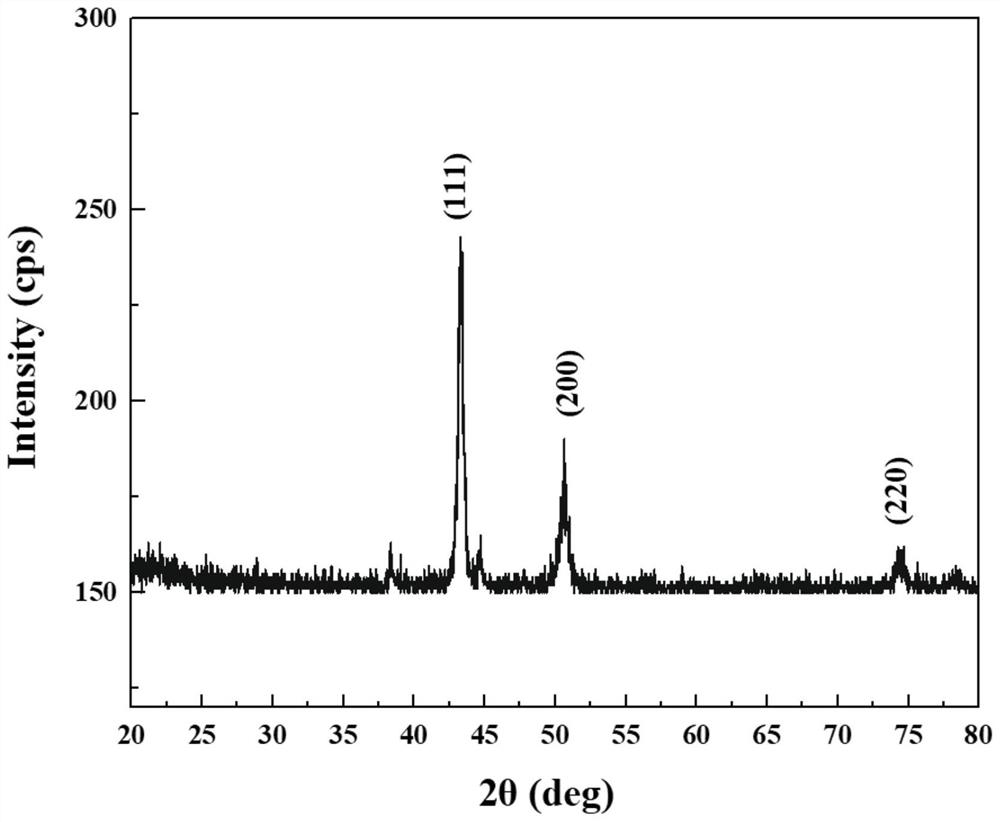

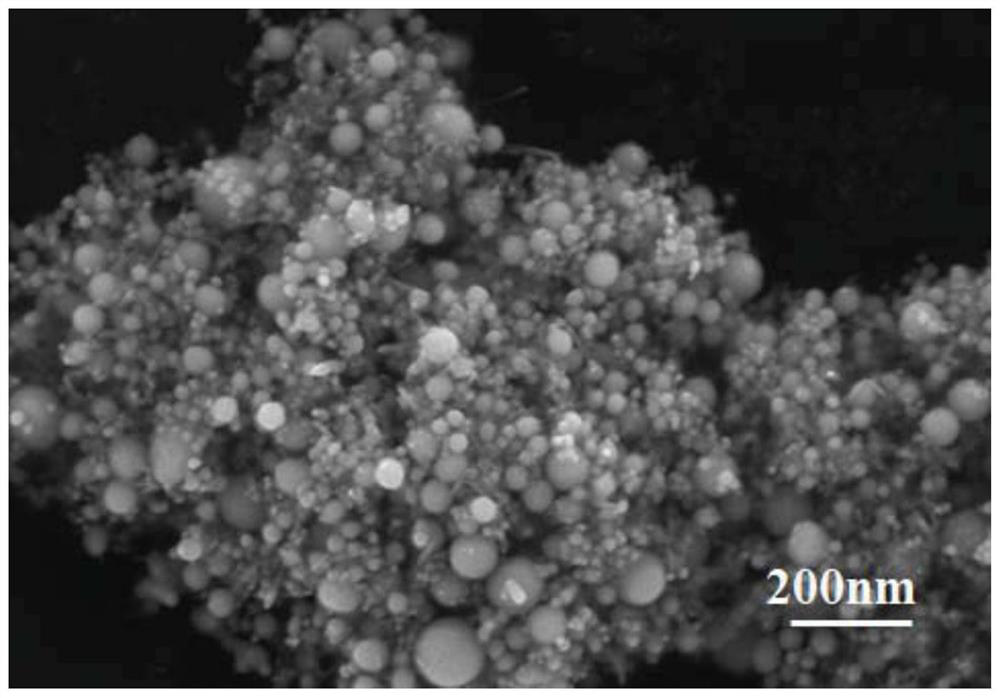

[0024] Weigh 29.01g of Co(NO 3 ) 2 .6H 2 O, 40.02g of Cr (NO 3 ) 3 .9H 2 O, 24.16g of Cu (NO 3 ) 2 .3H 2 O, 40.4g Fe (NO 3 ) 3 .9H 2 O and 29.08 g of Ni (NO 3 ) 2 .6H 2 O was dissolved in 100 mL of distilled aqueous solution containing 10 mL of ammonia water, and stirred to obtain a mixed solution containing metal salts; then 85.58 g of sucrose was weighed and added to the above mixed solution, and after stirring, the pH of the mixed solution was adjusted to 8 with ammonia water to obtain a transparent sol; then the above transparent sol was heated in an oil bath at 110°C to remove solvent water to obtain a loose, foamy gel, which was further heated at 110°C for 20 min to obtain a solid precursor; then the above solid precursor was The body was placed in a vacuum tube furnace at 400 °C for 30 minutes to undergo redox reaction, and then a reducing gas H was introduced. 2 Continue to react for 10min to obtain a face-centered cubic crystal structure (such as figure...

Embodiment 2

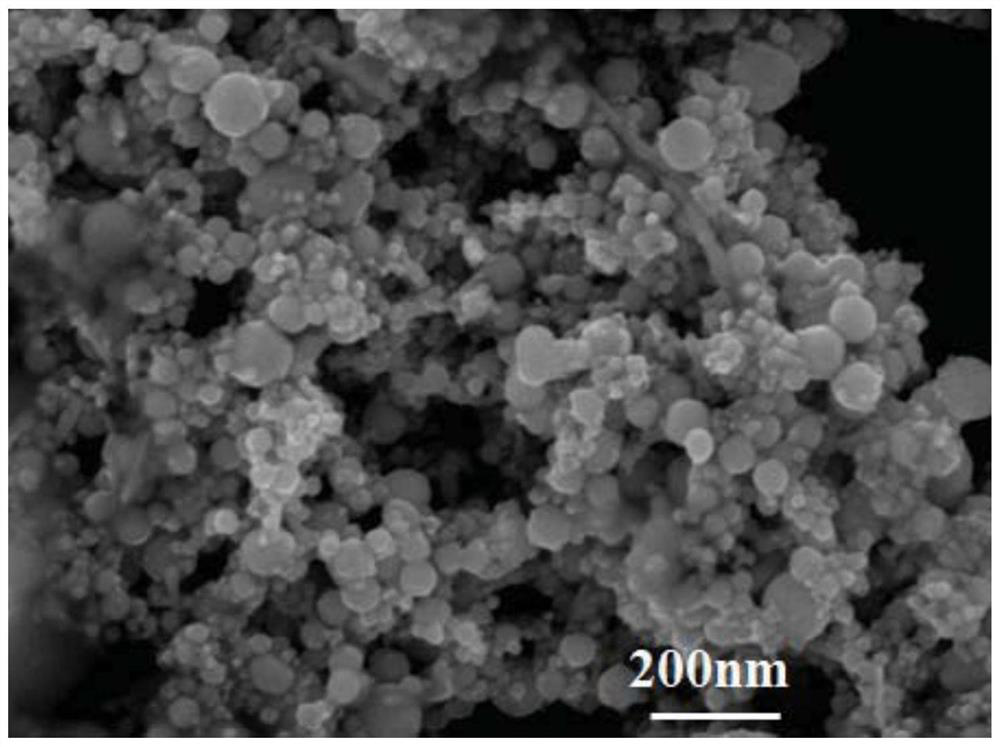

[0026] Weigh 29.01g of Co(NO 3 ) 2 .6H 2 O, 40.02g of Cr (NO 3 ) 3 .9H 2 O, 24.16g of Cu (NO 3 ) 2 .3H 2 O, 40.4g Fe (NO 3 ) 3 .9H 2 O, 29.08g of Ni (NO 3 ) 2 .6H 2 O and 9.10 g of Zn (NO 3 ) 2 .6H 2O was dissolved in 50 mL of distilled aqueous solution containing 5 mL of ammonia water, stirred evenly to obtain a mixed solution containing metal salts; then weighed 25.125 g of hexamethyltetramine and 52.60 g of ethylenediaminetetraacetic acid and added it to the above mixed solution, stirred evenly, and used Ammonia water adjusted the pH of the mixed solution to 7 to obtain a transparent sol; then the above transparent sol was heated in an oil bath at 150°C to remove the solvent water to obtain a loose, foamy gel, which was further heated at 150°C Heating for 50min to obtain a solid precursor; then the above-mentioned solid precursor is placed in a vacuum tube furnace at 500°C to undergo a redox reaction for 45min, and then a reducing gas H is introduced 2 Cont...

Embodiment 3

[0028] Weigh 21.83g of Co(NO 3 ) 2 .6H 2 O, 30.01g of Cr (NO 3 ) 3 .9H 2 O, 18.12g of Cu(NO 3 ) 2 .3H 2 O, 30.3g Fe (NO 3 ) 3 .9H 2 O, 21.81g of Ni (NO 3 ) 2 .6H 2 O and 12.74g AgNO 3 Dissolve in 50mL distilled water solution containing 5mL ammonia water, stir to obtain a mixed solution containing metal salt; then weigh 50.47g of hexamethyltetramine and add it to the above mixed solution, stir well and adjust the pH of the mixed solution with ammonia water to be 6, A transparent sol was obtained; then the above-mentioned transparent sol was heated in an oil bath at 200° C. to remove solvent water to obtain a loose, foamy gel, which was further heated at 200° C. for 40 min to obtain a solid precursor; then the The above-mentioned solid precursors were placed in a vacuum tube furnace at 600 ° C to undergo redox reaction for 60 minutes, and then the reducing gas H was introduced. 2 Continue to react for 20min to obtain AgCoCrCuFeNi hexa-alloy nano-powders with an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com