Vacuum melting furnace capable of continuous feeding and metal atomization powder making equipment composed of it

A vacuum melting furnace and melting furnace technology, which is applied in the field of vacuum melting furnaces and metal atomization powder making equipment, can solve the problems of unsuitable melting furnaces, etc., achieve the effects of shortening distance and feeding time, convenient operation, and improving appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

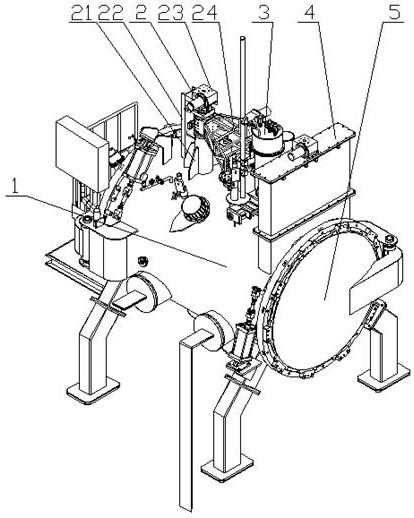

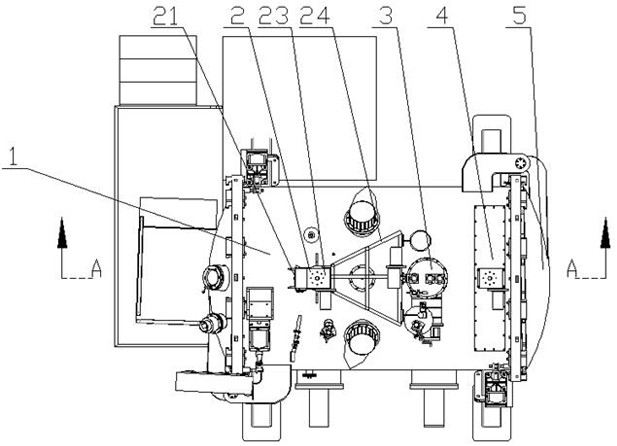

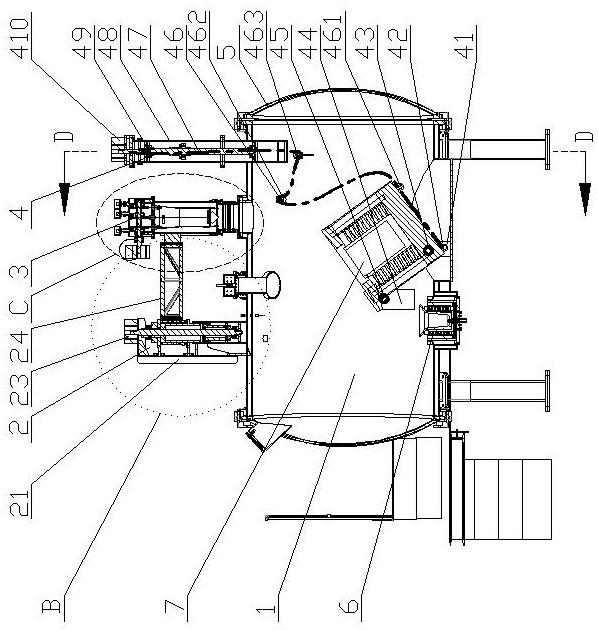

[0064] refer to Figure 1~11 : a kind of vacuum smelting furnace 7 capable of continuous charging of the present invention comprises a smelting cylinder 1, a smelting furnace 7, a feeding mechanism 4, a lifting turret mechanism 2 and a continuous feeding mechanism 3; the middle of the bottom of the smelting cylinder 1 A tundish 6 is provided, one side of which is provided with a furnace door 5; the melting furnace 7 is installed in the melting cylinder 1, and the melting furnace 7 is located on one side of the tundish 6; the melting furnace 7 is installed on the side of the melting cylinder 1 The upper dumping mechanism 4 performs flipping and dumping; the lifting turret mechanism 2 is installed on the upper side of the smelting cylinder 1, and is connected with the continuous feeding mechanism 3; The continuous feeding mechanism 3, the continuous feeding mechanism 3 is installed in the feeding port 36 directly above the smelting furnace 7; the continuous feeding mechanism 3 i...

Embodiment 2

[0103] A metal atomization pulverization equipment with continuous feeding furnace of the present invention comprises the vacuum smelting furnace 7 described in Embodiment 1, a metal atomization device, a vacuum system, a powder collection device, a control cabinet and an installation platform bracket, the The vacuum smelting furnace 7 is installed on the top of the installation platform bracket, and is provided with a continuous feeding device; the metal atomization device is installed below the metal smelting furnace 7, and its lower end is connected with the powder classification collection device; the vacuum system is installed on the metal mist One side of the atomization device, and connected to the upper end of the metal atomization device; the control cabinet is installed on different equipment installation platforms of the installation platform bracket, and connected with its corresponding control equipment.

[0104] The metal atomization device is a plasma atomization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com